Vertical reinforcement connection method of prefabricated hollow concrete composite shear wall

A technology of hollow concrete and laminated shear walls, which is applied in the fields of construction, building structure, and building material processing, can solve problems such as inconvenient operation, achieve reliable connection, and speed up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

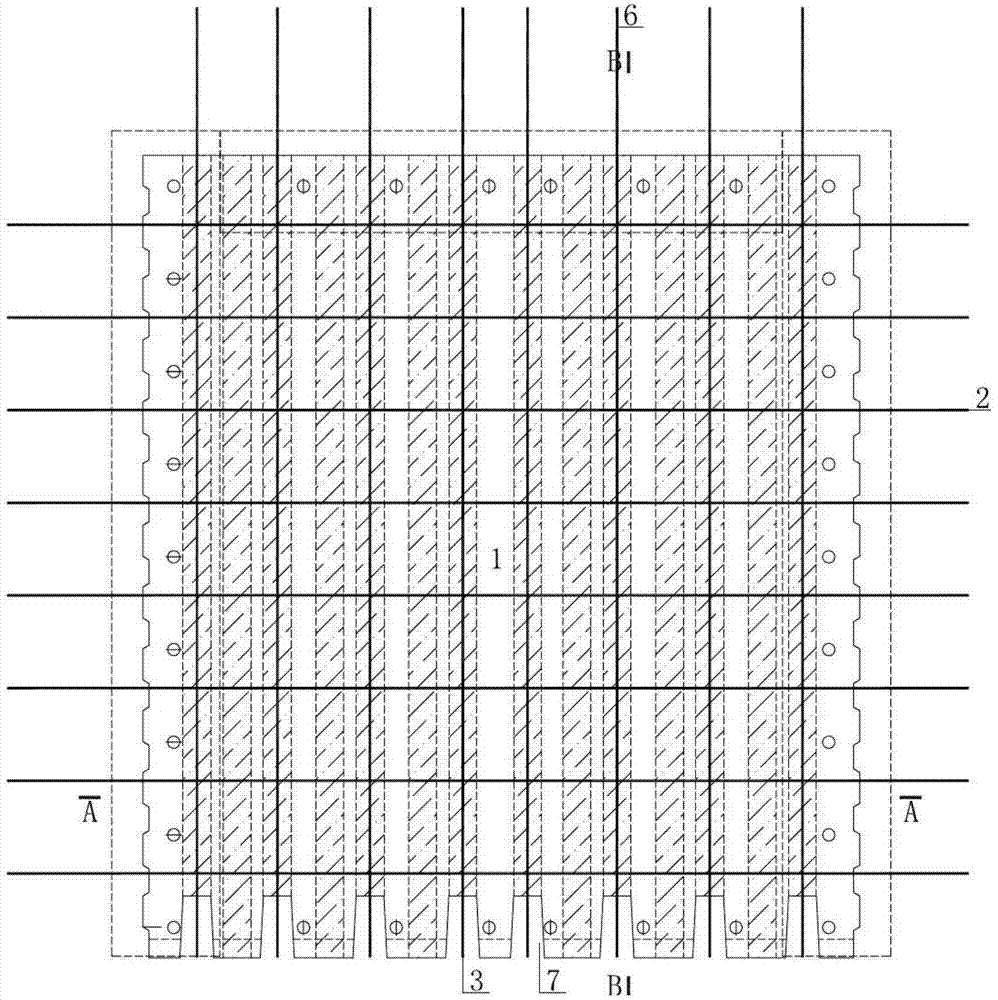

[0026] Specific embodiment 1 (standard floor position)

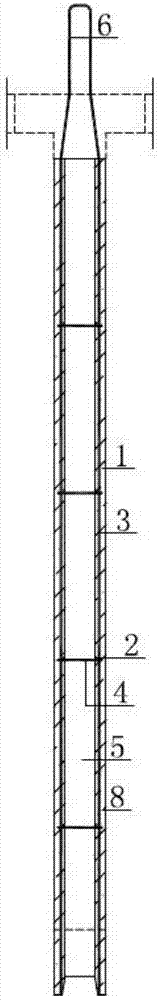

[0027] Step 1. At the end of the prefabricated shear wall member 1, reserve the vertical reinforcing bar 3 of the member to the upper part. The throwing length ranges from 15d to 40d, where d is the diameter of the vertical steel bars 3 of the component, and the spacing of the vertical external steel bars 6 of the component is the same as that of the vertical steel bars 3 of the component, which is 100mm to 300mm;

[0028] Step 2, the lower part of the prefabricated shear wall member 1 is provided with an installation slot 7;

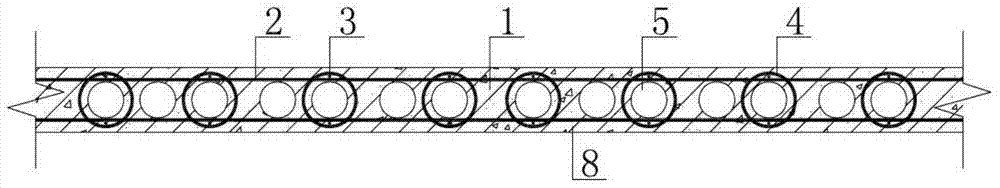

[0029] Step 3, the vertical reinforcing bars 3 of the component are located on both sides of the vertical hollow hole 5 of the component, and the vertical reinforcing bar 3 of the component bypasses the vertical hollow hole 5 of the component through the circular tie reinforcing bar 4 of the component to realize the tie;

[0030] Step 4. First, the vertical hollow hole 5 of the upper prefabricate...

specific Embodiment 2

[0032] Specific embodiment 2 (top level position)

[0033] Step 1. At the end of the prefabricated shear wall component 1, reserve the vertical reinforcement 3 of the prefabricated component to the upper part. When it is the top floor of a floor, the length of the prefabricated vertically thrown steel bars 6 is the top elevation of the floor roof minus 20mm, and the distance between the vertically thrown steel bars 6 of the prefabricated components is the same as that of the vertical steel bars 3 of the prefabricated components, which is 100mm ~300mm;

[0034] Step 3, the prefabricated component is anchored in the cast-in-place beam at the elevation of the top floor;

[0035] Step 4: By pouring concrete 9 into the hollow part of the prefabricated shear wall component 1, the installation of the prefabricated shear wall component 1 is completed, so that the prefabricated shear wall component 1 forms a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com