Inlaid frame manufacturing method for producing environment-friendly flame-retardant acoustic board

A technology with a built-in frame and a manufacturing method, which is applied in the directions of sound insulation, building components, fire prevention, etc., can solve the problems of sound-absorbing panels breaking and falling off, increasing construction difficulty, labor and time-consuming, etc., and achieving the effect of increasing the overall strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention will be further described:

[0025] Manufacturing method of the built-in frame for the production of environmentally friendly flame-retardant sound-absorbing panels:

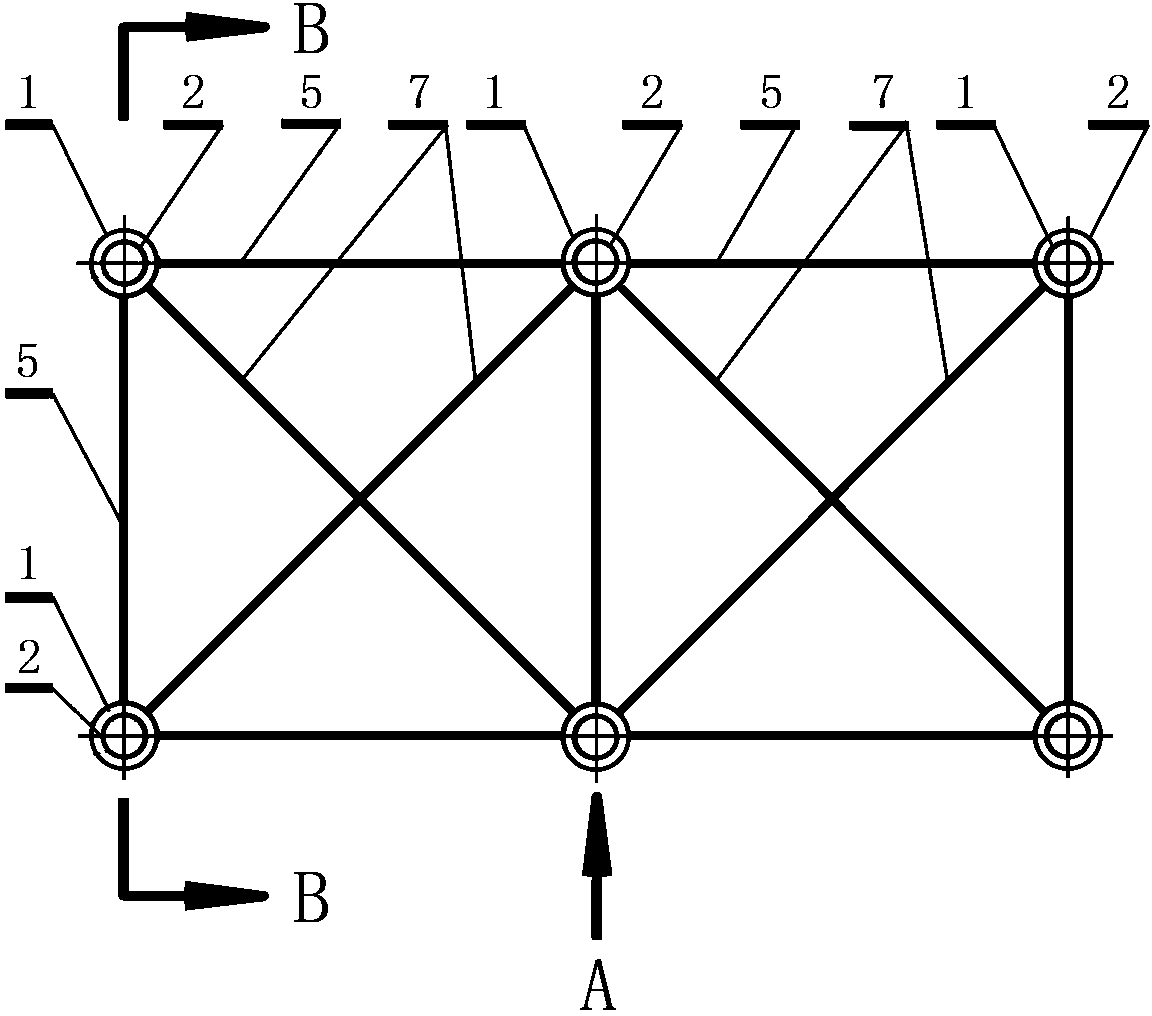

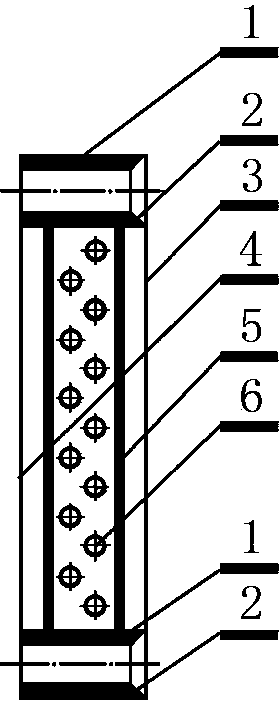

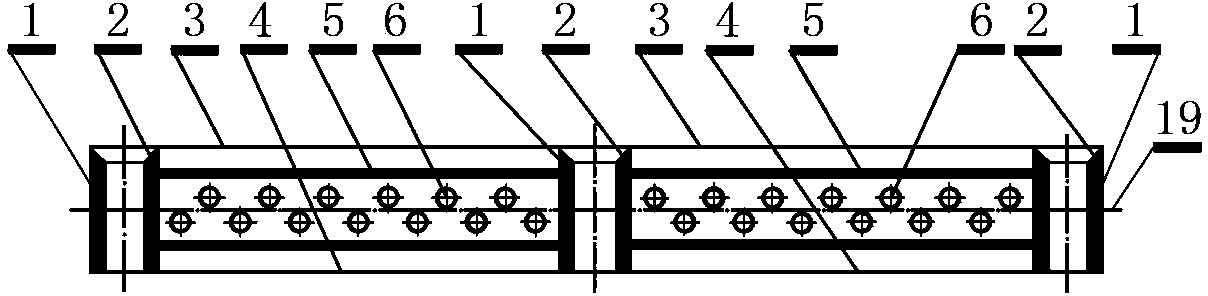

[0026] (1) The built-in frame used to produce environmentally friendly flame-retardant sound-absorbing panels is a rectangular steel structure frame, and the built-in frame is composed of 6 short steel pipes 1, 7 punched steel mesh 5 and 4 reinforcing ribs 7;

[0027] (2) The height of the short steel pipe 1 is controlled at 20 mm, the outer diameter is controlled at 12 mm, and the inner diameter is controlled at 8 mm. The expanded metal mesh 5 is welded into a rectangular frame, and the horizontal centerline 19 at 1 / 2 of the height of the short steel pipe 1 overlaps with the horizontal centerline 19 at 1 / 2 of the width of the punched steel mesh 5. In the rectangular frame, the short steel pipe 1 and the short The diagonal line at 1 / 2 of the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com