Oil leakage prevention heavy load terrace structure resisting deformation of foundation

A technology for foundation deformation and oil seepage prevention, applied in the field of building foundations, can solve the problems of difficult to meet the requirements of environmental protection departments to prevent oil seepage, difficult to oil-proof concrete floor surface, difficult to control the quality of painting, etc. The effect of controlling oil leakage, avoiding blind spots of anti-seepage, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

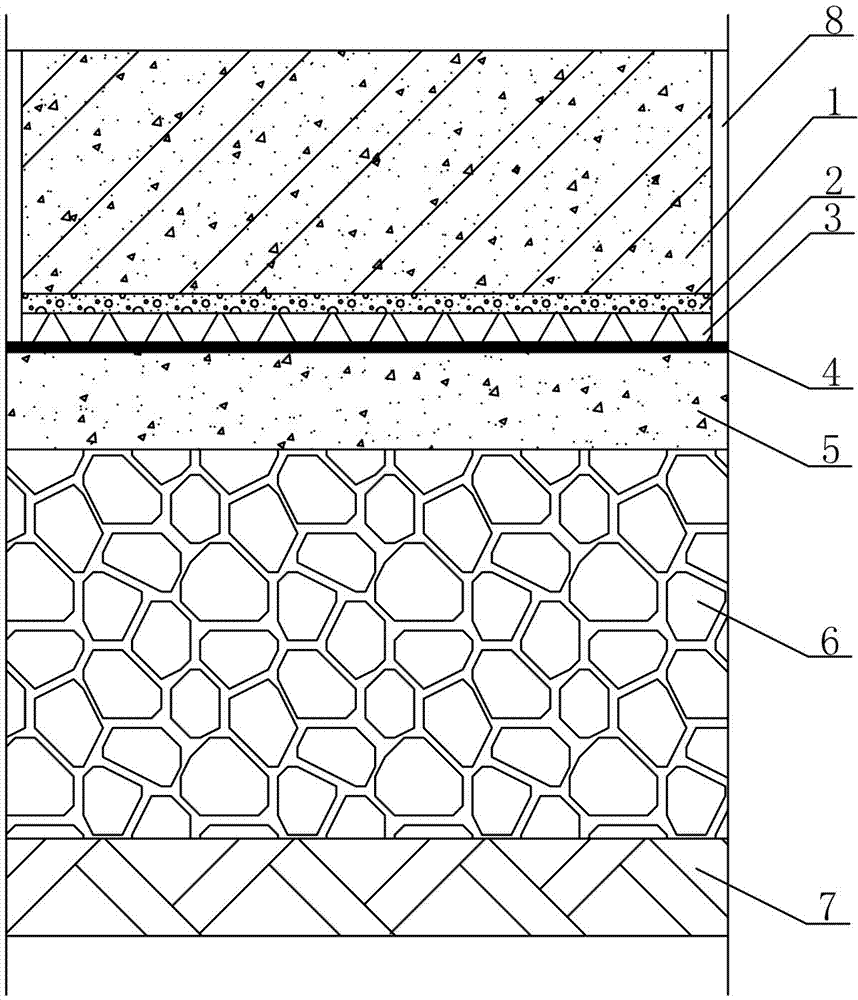

[0011] See attached figure 1 ~ attached figure 2 , the present invention is composed of a gravel cushion 6, a concrete cushion 5, a geomembrane 4, a composite diversion layer 3, a mortar layer 2 and an oil-resistant reinforced concrete surface layer 1 sequentially arranged on a foundation 7 rammed with plain soil. Oil floor, oil drainage ditch 8 is arranged around the anti-seepage oil floor. A composite diversion layer 3 and a geomembrane layer 4 are arranged between the concrete cushion 5 and the mortar layer 2; the composite diversion layer 3 is a diversion mesh sheet of a geomembrane for upper and lower composite water seepage and reverse filtration. , the diversion net sheet is a three-dimensional drainage channel structure, and the three-dimensional drainage channel confluences the seepage oil to the oil drainage trench 8; It overlaps with the geomembrane layer 4.

[0012] The present invention is constructed as follows: According to the geological conditions of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com