Photoelectric type high backfill earthwork settling volume testing device and mounting method thereof

A testing device and settlement technology, which can be used in measuring devices, height/level measurement, and on-site foundation soil survey, etc. It can solve problems such as construction inconvenience and errors, and achieve the effects of convenient operation, high precision and large measuring range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

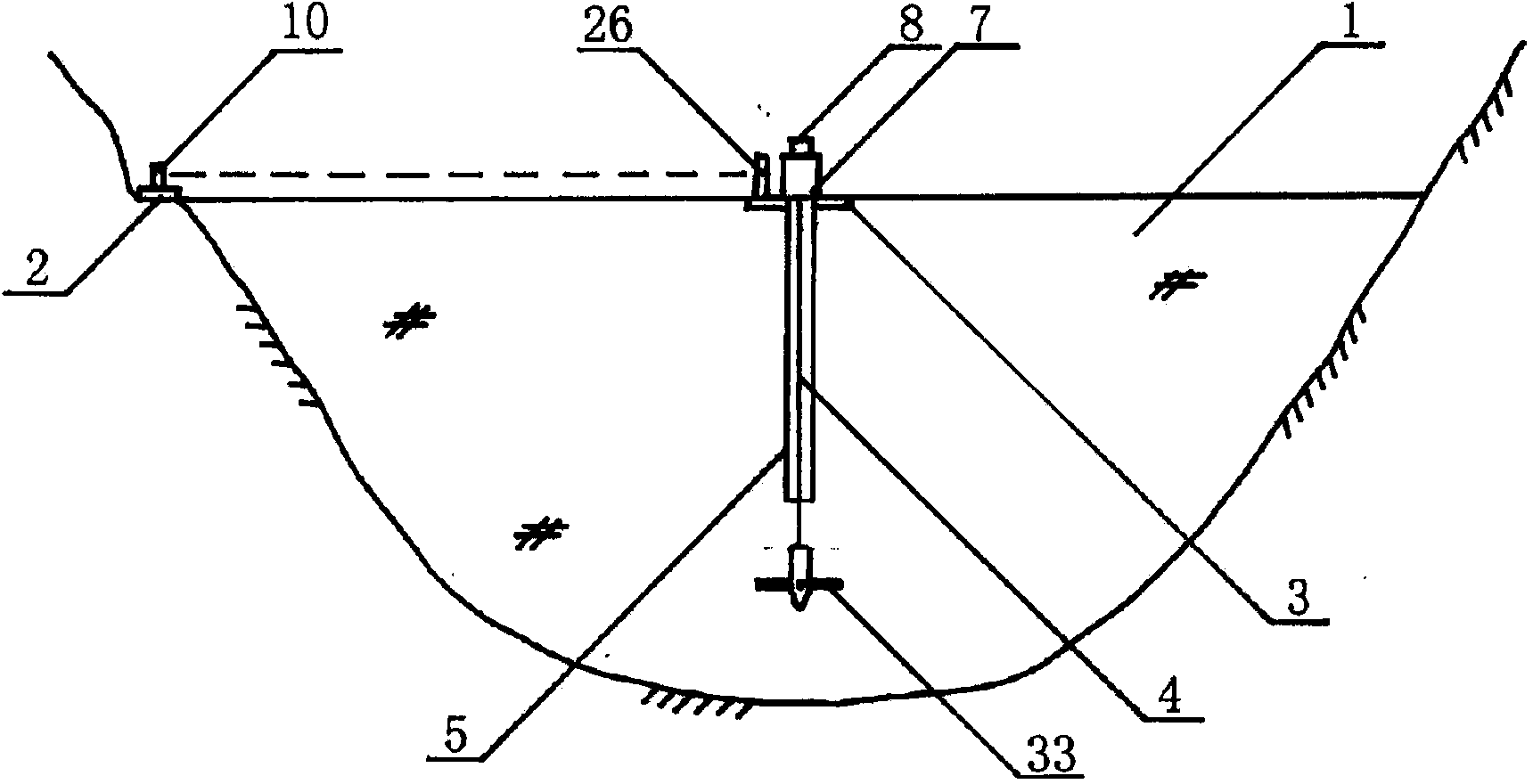

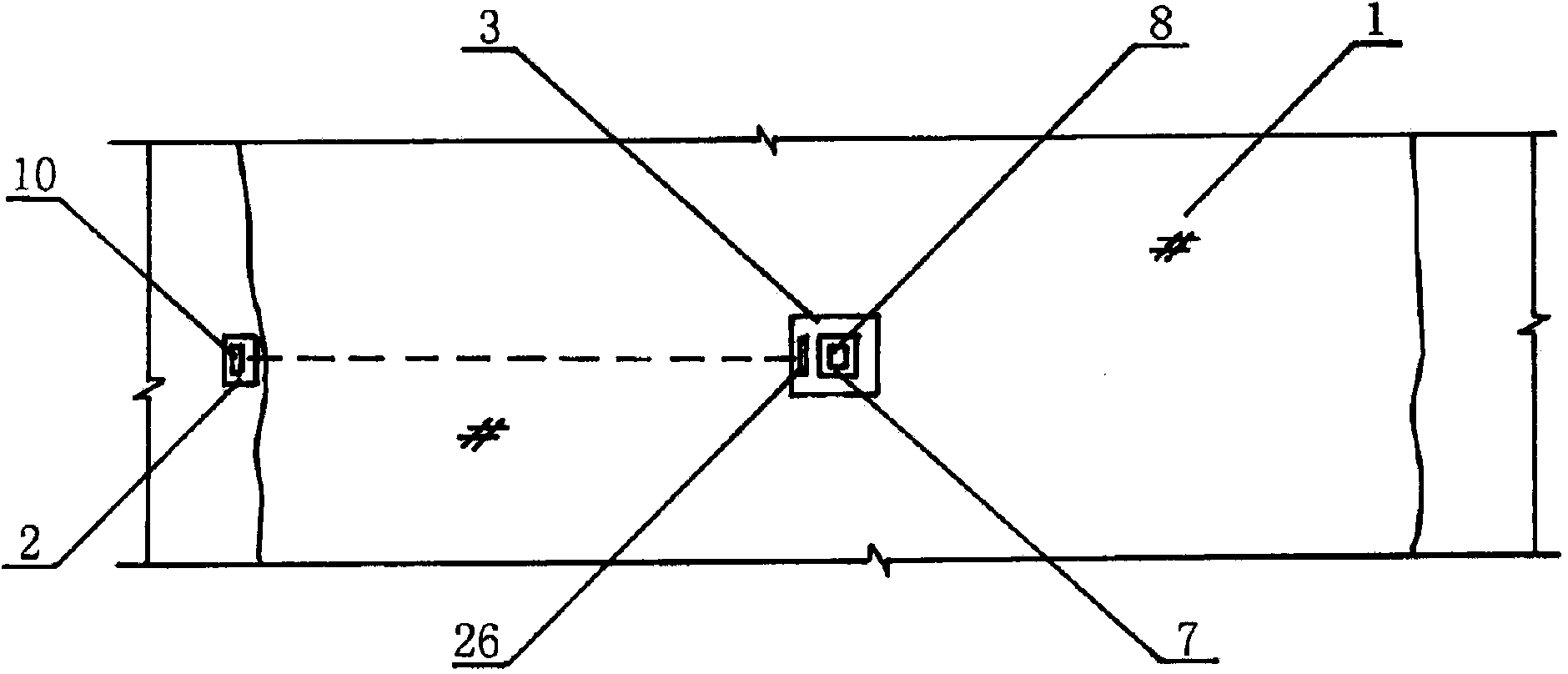

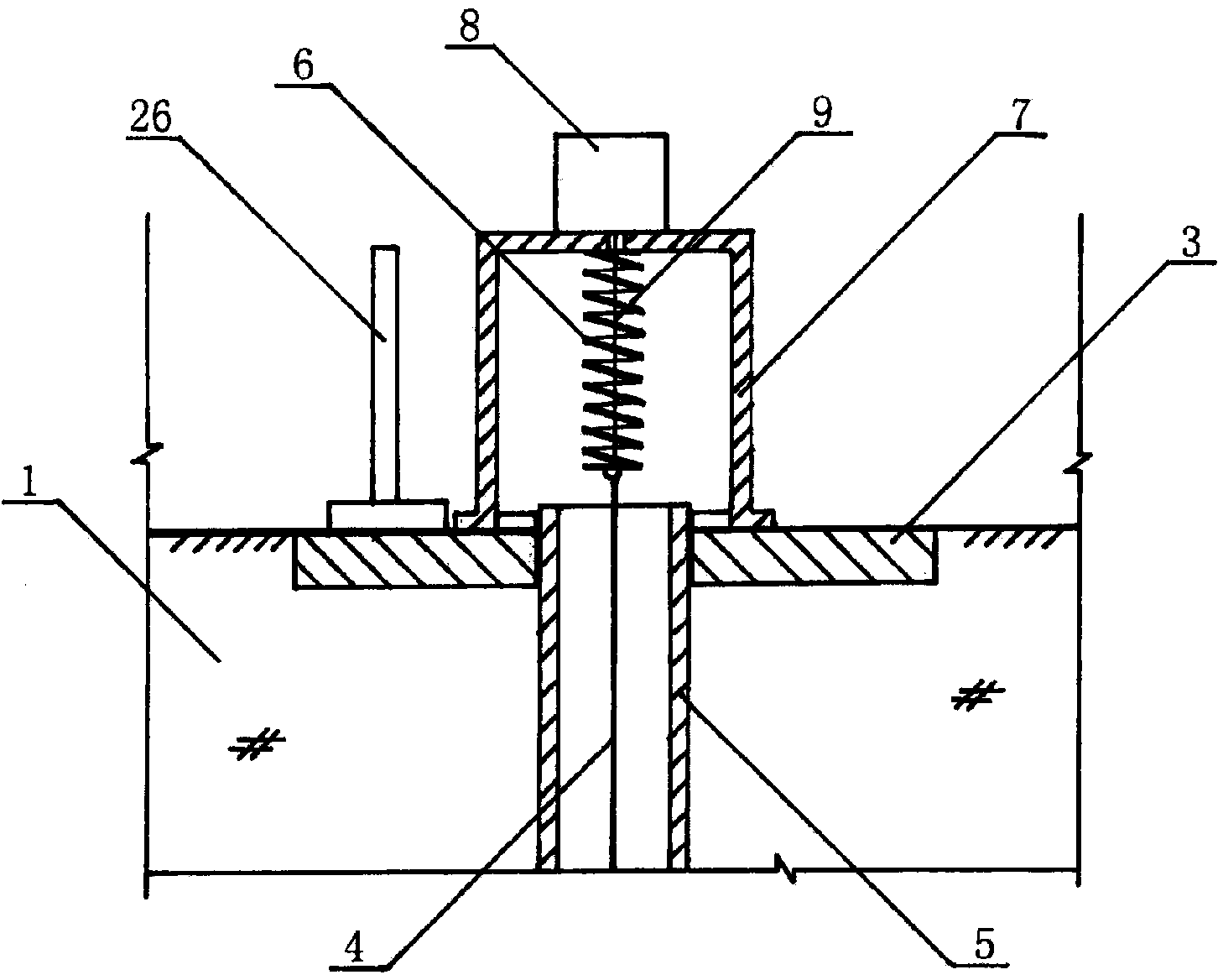

[0034] see Figure 1 to Figure 12 , is a kind of optoelectronic type high-fill earthwork settlement test device of the present invention, comprising top surface settlement test device, soil subsidence test device, is characterized in that: the horizontal laser reference device 10 of described top surface settlement test device is arranged On the test bench a2 at the relatively non-displacement place, the optical guide wire displacement sensor 26 of the top surface settlement test device is placed on the test bench b3 at the top test point of the high fill earthwork 1, and the horizontal laser reference device 10 sends a horizontal laser to the optical guide wire displacement sensor 26, and when the top surface of the high fill earthwork 1 settles, the laser point emitted by the horizontal laser reference device 10 to the optical guide wire displacement sensor 26 will move upwards, and the The optical guide wire type displacement sensor 26 outputs the signal of the settlement a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com