Method for preparing anion far-infrared short fibers employing waste renewable polyester bottle flakes

A far-infrared negative ion, recycled polyester technology, applied in the chemical characteristics of fibers, single-component polyester rayon, melt spinning, etc. It can achieve excellent radiation protection effect, easy industrialization implementation, and the effect of solving environmental protection problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

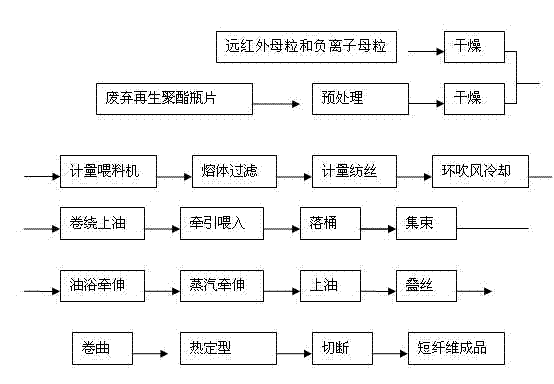

Image

Examples

Embodiment 1

[0040] Pre-treatment (including sorting, crushing and cleaning) and drying of waste recycled PET bottle flakes are carried out, and then the washed bottle flakes are put into the vacuum drum dryer. Steam or heat transfer oil, rotate the drum at the same time, keep the temperature at 140 ℃, start the vacuum pump at the same time, keep the vacuum at 0.08MPa, dry for 9 hours, the moisture content of the dried polyester bottle flakes is 90, and the far-infrared mother The granules and negative ion masterbatch are dried. The drying process is mainly to put them into a sealed silo, and the bottom of the silo is fed with dried hot air, the temperature is kept at 125 °C, and the drying time is 10.5 hours. And the moisture content of negative ion masterbatch is 55ppm.

[0041] Then, the dried waste recycled PET bottle flakes, far-infrared masterbatch and negative ion masterbatch are sent to the metering feeder for mixing. The dried far-infrared masterbatch and negative ion masterbatch...

Embodiment 2

[0046] Pre-treatment (including sorting, crushing and cleaning) and drying of waste recycled PET bottle flakes are carried out, and then the washed bottle flakes are put into the vacuum drum dryer. Steam or heat transfer oil, rotate the drum at the same time, keep the temperature at 150 ℃, start the vacuum pump at the same time, keep the vacuum degree at 0.09MPa, the drying time is 11 hours, the moisture content of the dried polyester bottle flakes is below 85ppm, and the remote The infrared masterbatch and the negative ion masterbatch are dried. The drying process is mainly to put the far infrared masterbatch and the negative ion masterbatch into the sealed silo. The bottom of the silo is fed with dry hot air, and the temperature is kept at 135 ° C and the drying time is 11 hour, the moisture content of the dried far-infrared masterbatch and negative ion masterbatch is 50ppm.

[0047] Then, the dried waste recycled PET bottle flakes, far-infrared masterbatch and negative ion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com