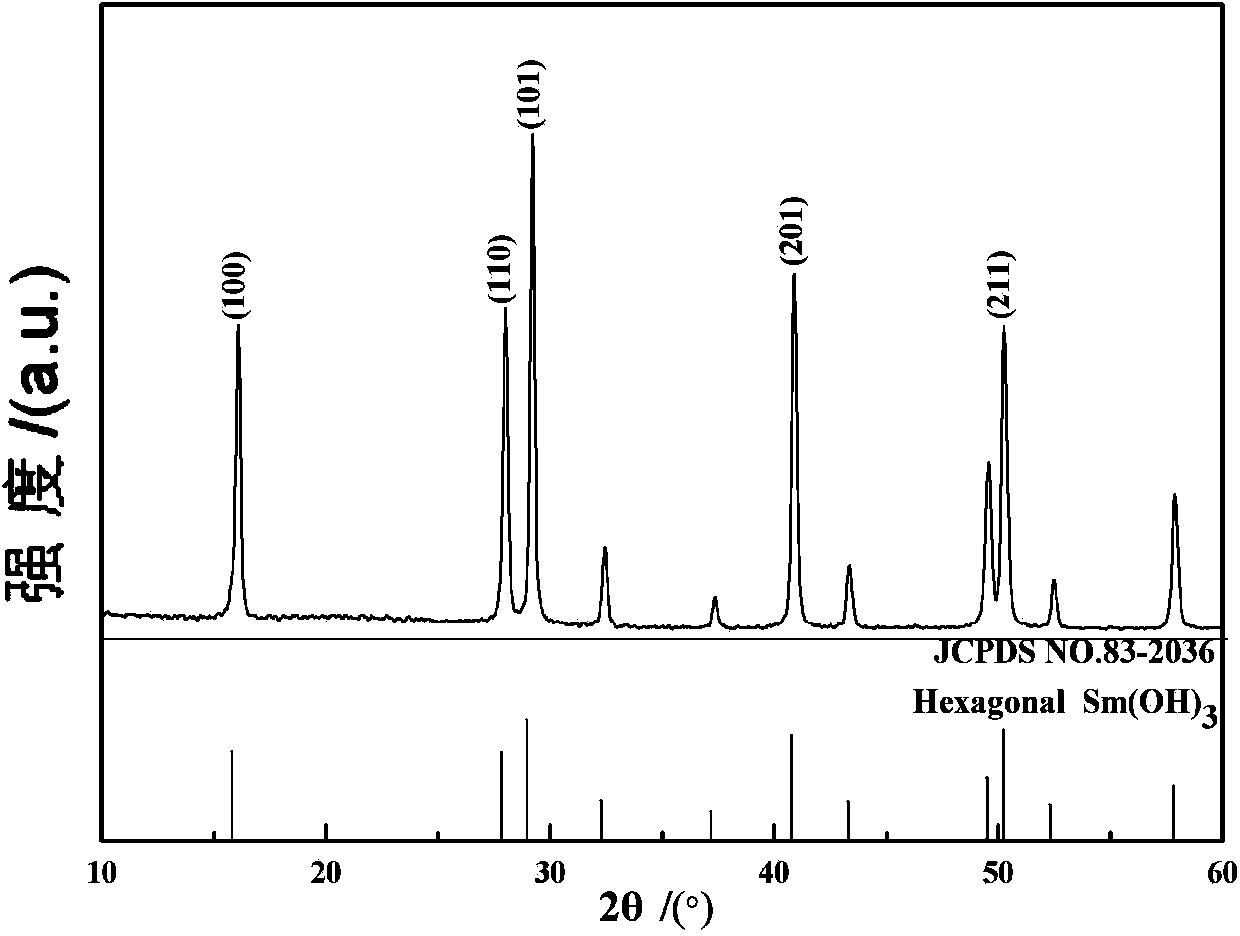

Preparation method of hexagonal-prism-shaped Sm(OH)3 nanocrystalline

A nanocrystal and hexagonal prism technology is applied in the field of preparation of nano-semiconductor materials, which can solve the problems of weak crystallinity and uneven product size distribution, and achieve the effects of strong crystallinity, controllable grain growth and strong feasibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Analytical pure Sm(NO 3 ) 3 ·6H 2 O was dissolved in 30mL distilled water to make Sm 3+ Solution A with a concentration of 0.025mol / L;

[0020] 2) Under magnetic stirring, use analytically pure diethylenetriamine to adjust the pH value of solution A to 9.0, and continue stirring for 1.5 hours to form a reaction precursor;

[0021] 3) Pour the reaction precursor liquid into the hydrothermal reaction kettle, the filling ratio is controlled at 60%, and the hydrothermal kettle is sealed, then put into the electric blast drying oven, and react at 120°C for 8 hours, and cool naturally after the reaction to room temperature, then open the hydrothermal kettle, and filter the suspension obtained in the hydrothermal kettle to obtain a solid product; the solid product is successively washed by centrifugation with distilled water and absolute ethanol, and the number of times of centrifugal washing is 4 to 6 times, and then The washed solid product was dried in an electric va...

Embodiment 2

[0023] 1) Analytical pure Sm(NO 3 ) 3 ·6H 2 O was dissolved in 33mL distilled water to form Sm 3+ Solution A with a concentration of 0.150mol / L;

[0024] 2) Under magnetic stirring, use analytically pure diethylenetriamine to adjust the pH value of solution A to 9.5, and continue stirring for 1 hour to form a reaction precursor;

[0025] 3) Pour the reaction precursor liquid into the hydrothermal reaction kettle, the filling ratio is controlled at 66%, and the hydrothermal kettle is sealed, then put into the electric blast drying oven, and react at 100°C for 12h, and cool naturally after the reaction to room temperature, then open the hydrothermal kettle, and filter the suspension obtained in the hydrothermal kettle to obtain a solid product; the solid product is successively washed by centrifugation with distilled water and absolute ethanol, and the number of times of centrifugal washing is 4 to 6 times, and then The washed solid product was placed in an electric vacuum o...

Embodiment 3

[0027] 1) Analytical pure Sm(NO 3 ) 3 ·6H 2 O was dissolved in 33mL distilled water to form Sm 3+ Solution A with a concentration of 0.055mol / L;

[0028] 2) Under magnetic stirring, use analytically pure diethylenetriamine to adjust the pH value of solution A to 9.7, and continue stirring for 1.5 hours to form a reaction precursor;

[0029] 3) Pour the reaction precursor liquid into the hydrothermal reaction kettle, the filling ratio is controlled at 66%, and the hydrothermal kettle is sealed, and then put into the electric blast drying oven, and react at 120°C for 24h, and naturally cool to At room temperature, open the hydrothermal kettle again, and filter the suspension obtained in the hydrothermal kettle to obtain a solid product; the solid product is sequentially washed with distilled water and absolute ethanol, and the number of centrifugal washing is 4 to 6 times, and then the washed The final solid product was placed in an electric vacuum oven and dried at 60°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com