Membrane refining process of medicinal sodium chloride

A technology of sodium chloride and membrane method, applied in the field of refining process of medicinal sodium chloride, can solve the problems of low production efficiency, long time-consuming, product quality decline, etc., and achieves prolonging the brushing cycle, reducing production costs, and resisting pollution. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

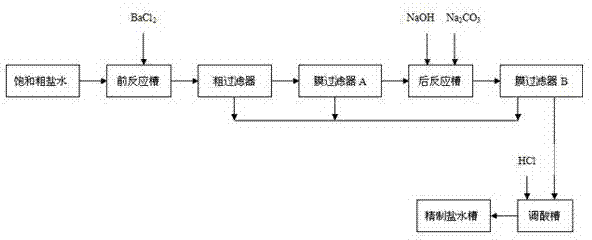

Image

Examples

Embodiment 1

[0038] 1. The sodium chloride content in saturated brine is 285g / L, the calcium content is 0.78g / L, the magnesium content is 0.10g / L, the sulfate content is 1.6g / L, and the suspended matter content is 1.05g / L. Add 3.47g / L of barium chloride solid into the front reaction tank, let it stand for 1h after mechanical stirring, intercept large particles of mechanical impurities through the screening device, and then carry out cross-flow filtration through the inorganic first membrane filter to remove the impurities in the feed liquid. Suspended solids and sulfate ions were sampled and tested, and the barium content was 82mg / L, the sulfate content was 0.86mg / L, and the SS content was ≤0.5mg / L. The pore size of the inorganic first membrane filter is 20nm, the filtration temperature is 75°C, the membrane surface flow velocity is 2m / s, the operating pressure is 0.2Mpa, and the stable flux of cross-flow filtration is about 269 L / m -2 h.

[0039]2. After passing through the first inorgan...

Embodiment 2

[0046] 1. The sodium chloride content in saturated brine is 285g / L, the calcium content is 0.78g / L, the magnesium content is 0.10g / L, the sulfate content is 1.6g / L, and the suspended matter content is 1.05g / L. Add 3.47g / L of barium chloride solid into the front reaction tank, let it stand for 1h after mechanical stirring, intercept large particles of mechanical impurities through the screening device, and then carry out cross-flow filtration through the inorganic first membrane filter to remove the impurities in the feed liquid. Suspended solids and sulfate ions were sampled and tested, and the barium content was 82mg / L, the sulfate content was 0.86mg / L, and the SS content was ≤0.5mg / L. The pore size of the inorganic first membrane filter is 20nm, the filtration temperature is 75°C, the membrane surface flow velocity is 2m / s, the operating pressure is 0.2Mpa, and the stable flux of cross-flow filtration is about 267 L / m -2 h.

[0047] 2. The clear liquid through the inorganic...

Embodiment 3

[0054] 1. The sodium chloride content in saturated brine is 285g / L, the calcium content is 0.78g / L, the magnesium content is 0.10g / L, the sulfate content is 1.6g / L, and the suspended matter content is 1.05g / L. Add 3.47g / L of barium chloride solid into the front reaction tank, let it stand for 1h after mechanical stirring, intercept large particles of mechanical impurities through the screening device, and then carry out cross-flow filtration through the inorganic first membrane filter to remove the impurities in the feed liquid. Suspended solids and sulfate ions were sampled and tested, and the barium content was 82mg / L, the sulfate content was 0.86mg / L, and the SS content was ≤0.5mg / L. The pore size of the inorganic first membrane filter is 20nm, the filtration temperature is 75°C, the membrane surface flow velocity is 2m / s, the operating pressure is 0.2Mpa, and the stable flux of cross-flow filtration is about 268 L / m -2 h.

[0055] 2. After the clear liquid of the inorgani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com