Preparation method of graphene-ZnO nanoparticle composite material

A nanoparticle and composite material technology, applied in the field of nanomaterial manufacturing, can solve the problems of high product energy consumption, large ZnO nanoparticle size, complex process, etc., and achieve the effect of reducing the grain size and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The raw materials graphene oxide and zinc chloride are dissolved in deionized water according to the mass ratio of 1:1, mixed evenly by ultrasonic, then centrifuged and cleaned;

[0015] Heat the obtained product in air to 1000 degrees Celsius for 5 seconds, and take out the product after cooling to room temperature to obtain a graphene-ZnO nanoparticle composite material.

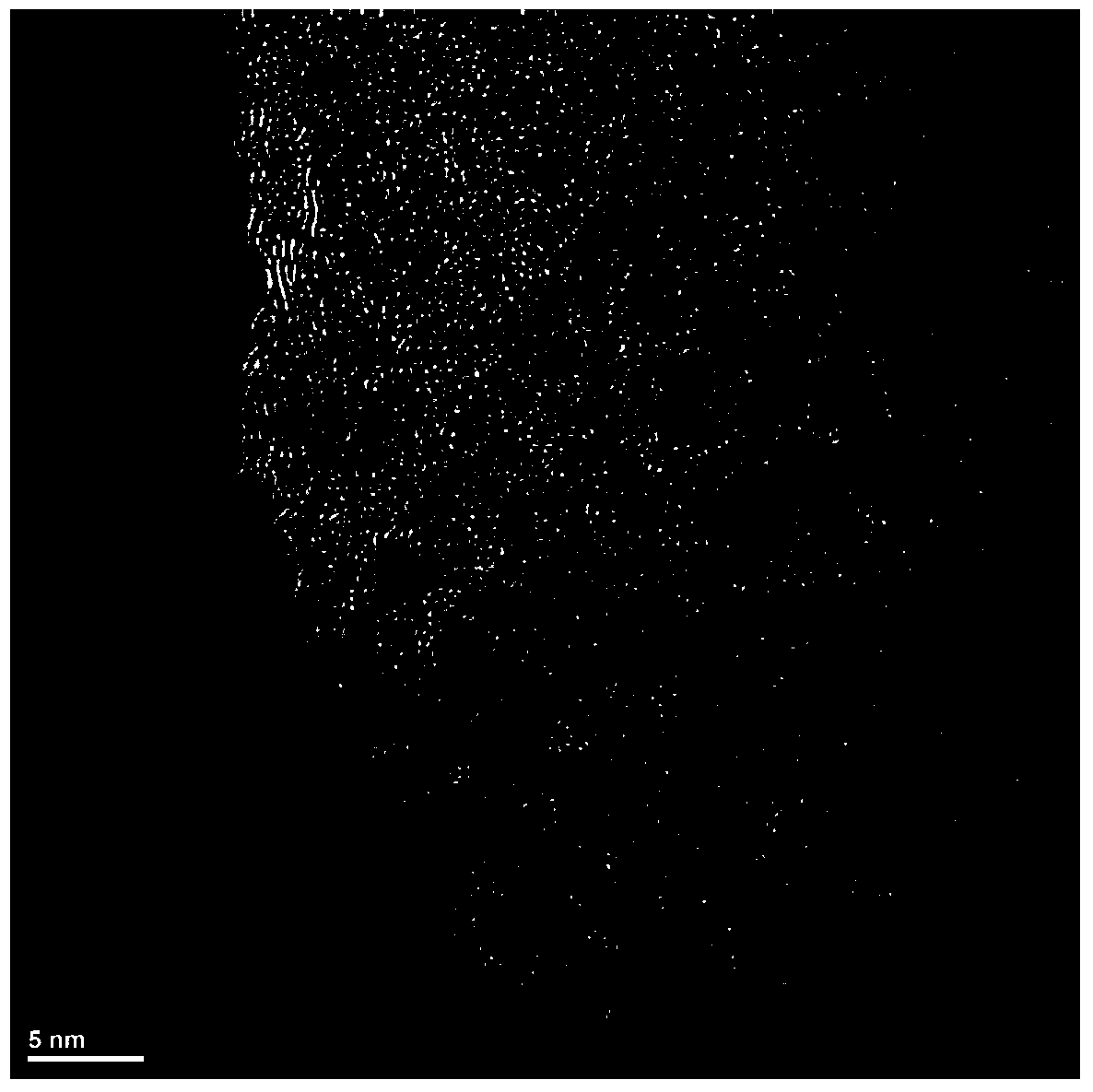

[0016] The product was characterized by transmission electron microscopy, and the results were as follows: figure 1 As shown, it can be seen that ZnO nanoparticles are attached to the graphene surface, and the ZnO particle size is less than 10 nm.

Embodiment 2

[0018] The raw material graphene oxide and zinc sulfate are dissolved in deionized water according to the ratio of 10:1 in mass ratio, stirred and mixed evenly, separated by filtration and cleaned;

[0019] The obtained product was heated to 150 degrees Celsius in an oxygen environment for heat treatment for 10 hours, and after the product was cooled to room temperature, it was taken out to obtain a graphene-ZnO nanoparticle composite material.

[0020] The obtained result is similar to Example 1.

Embodiment 3

[0022] The raw material graphene oxide and zinc phosphate are dissolved in deionized water according to the mass ratio of 1:10, and then centrifuged and cleaned after stirring and mixing evenly;

[0023] The obtained product was heated to 500 degrees Celsius in air for heat treatment for 2 hours, and after the product was cooled to room temperature, it was taken out to obtain a graphene-ZnO nanoparticle composite material.

[0024] The obtained result is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com