Automatic leveling telescoping boom engineering vehicle with fork head

A telescopic boom and automatic leveling technology, which is applied to cranes and other directions, can solve problems such as easy access to upper wires, small working space of cranes, and limited activities, so as to facilitate disassembly and maintenance, increase activity space, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

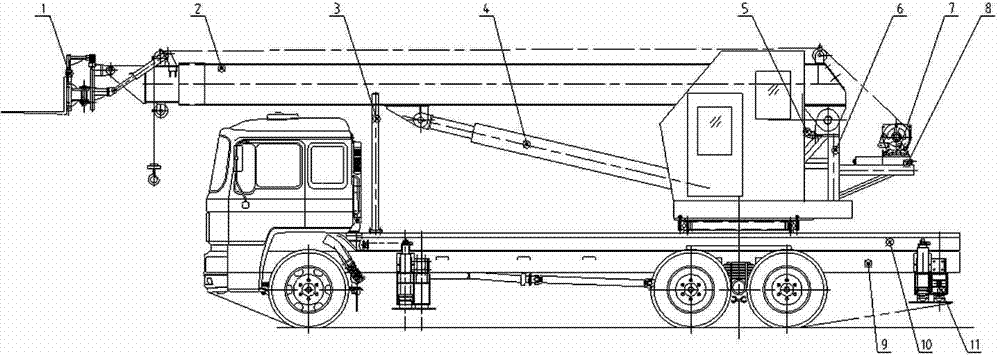

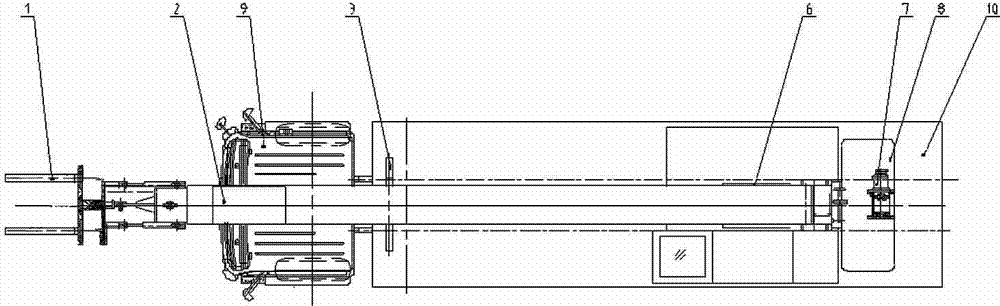

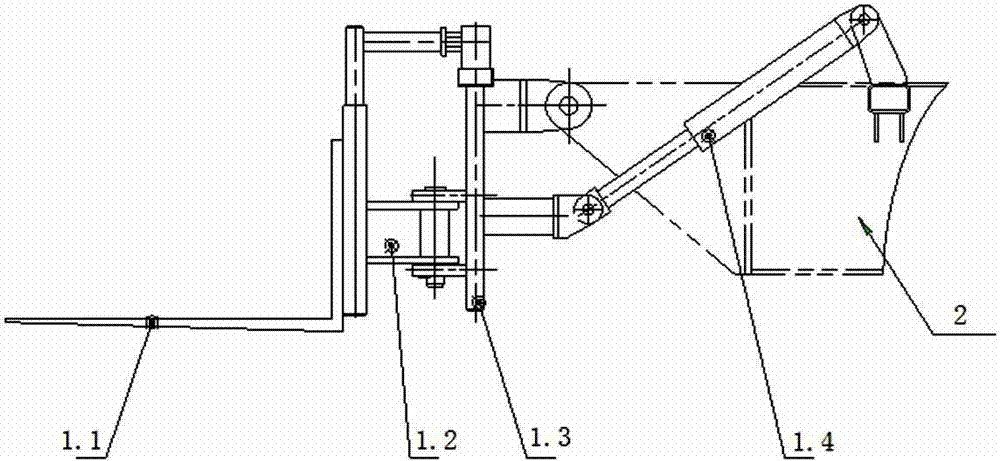

[0025] Such as figure 1 , figure 2 As shown in the figure, an engineering vehicle with a fork that can automatically level the telescopic boom is mainly used for hoisting objects that are far away or high and the hoisting space is limited to a certain extent. The detachable H-shaped outriggers ensure the stability of the engineering vehicle when forklifting heavy objects. It includes fork head assembly 1, boom assembly 2, bracket 3, lifting hydraulic cylinder 4, leveling device 5, slewing mechanism 6, hydraulic winch 7, counterweight 8, frame 9, subframe 10, H Type hydraulic outrigger assembly 11. The fork head assembly 1 is hinged to the boom assembly 2, the bracket 3 is connected to the subframe 10 through bolts, one end of the lifting hydraulic cylinder 4 is hinged to the middle of the boom assembly 2, and the other end is hinged to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com