Cleaning device for back face of breathable net belt of artificial board preforming press

A cleaning device and ventilation net technology, applied in cleaning methods and tools, cleaning methods using tools, and dust removal, etc., can solve problems such as inability to remove fiber impurities, cracking of slabs, and inability to remove gas, so as to reduce the workshop environment Pollution, reduce scrap rate, improve product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

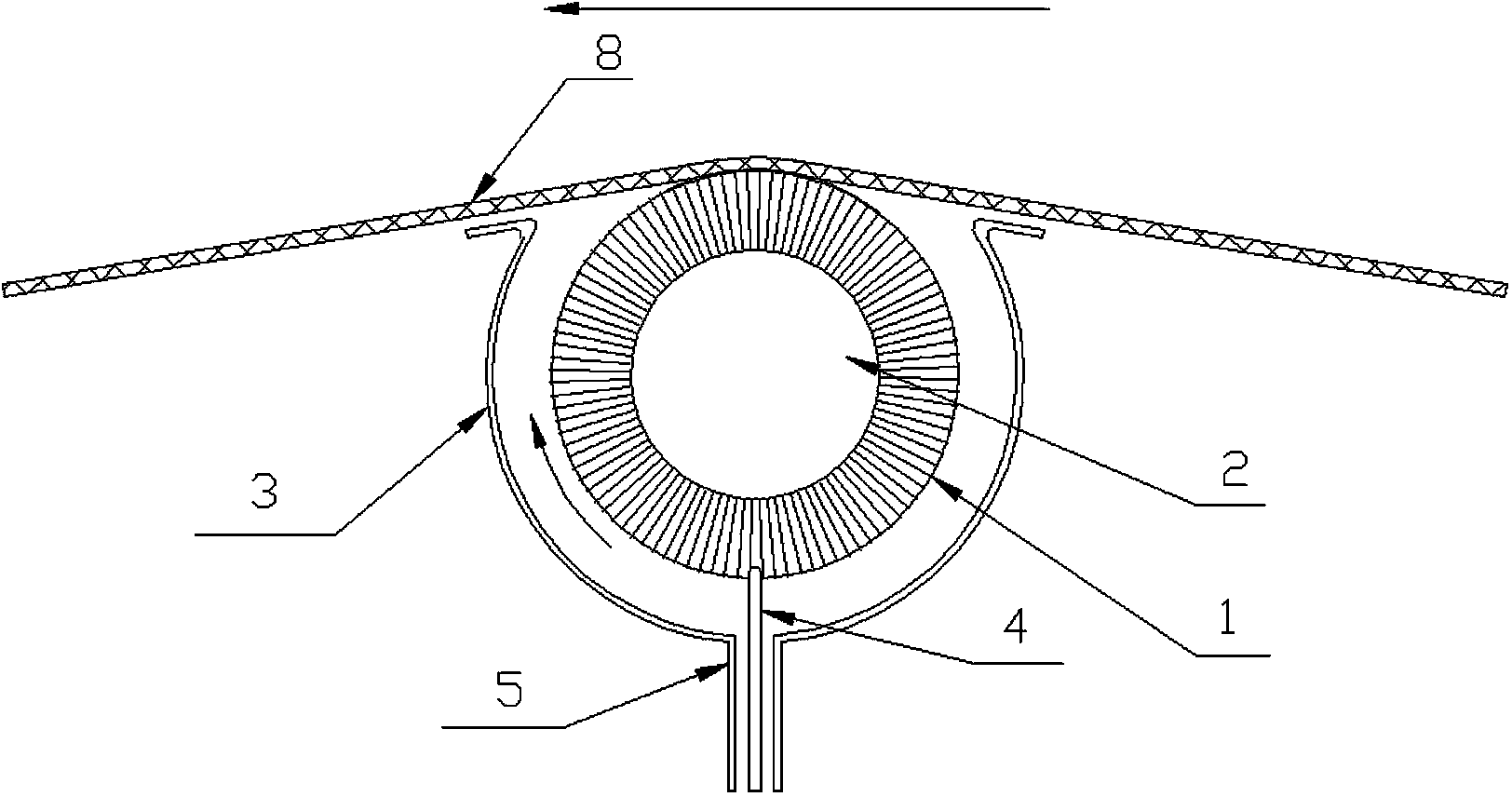

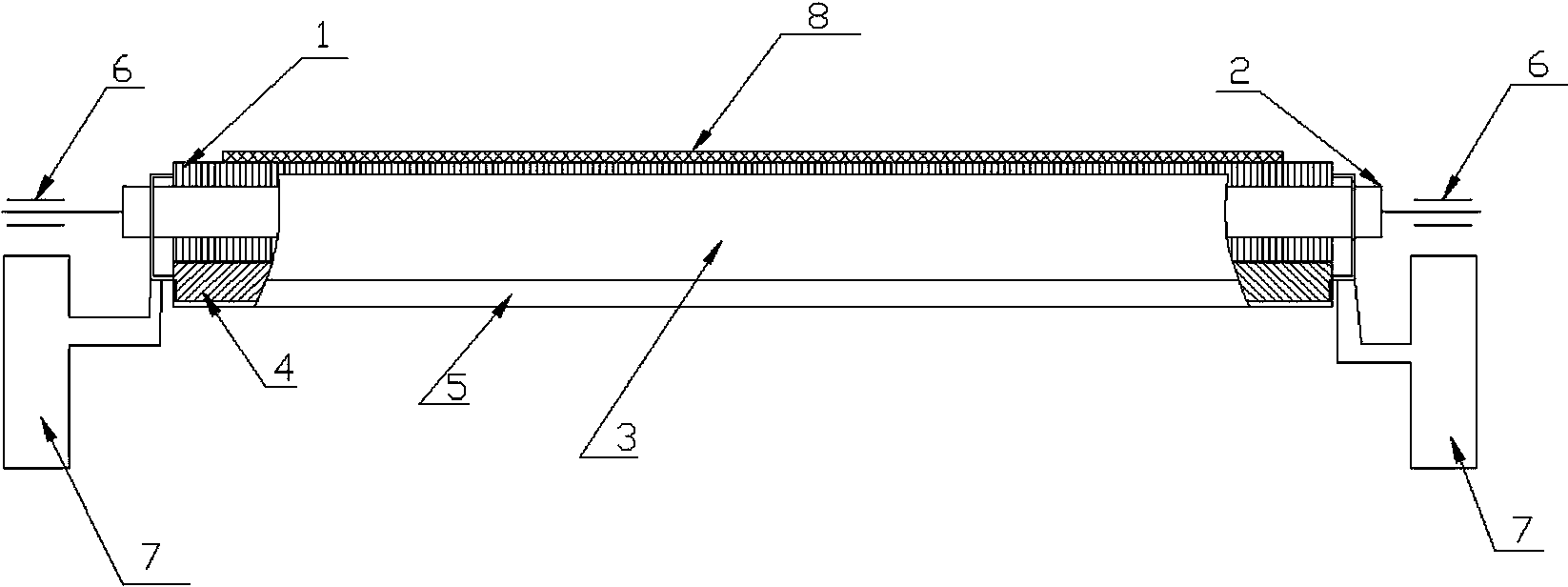

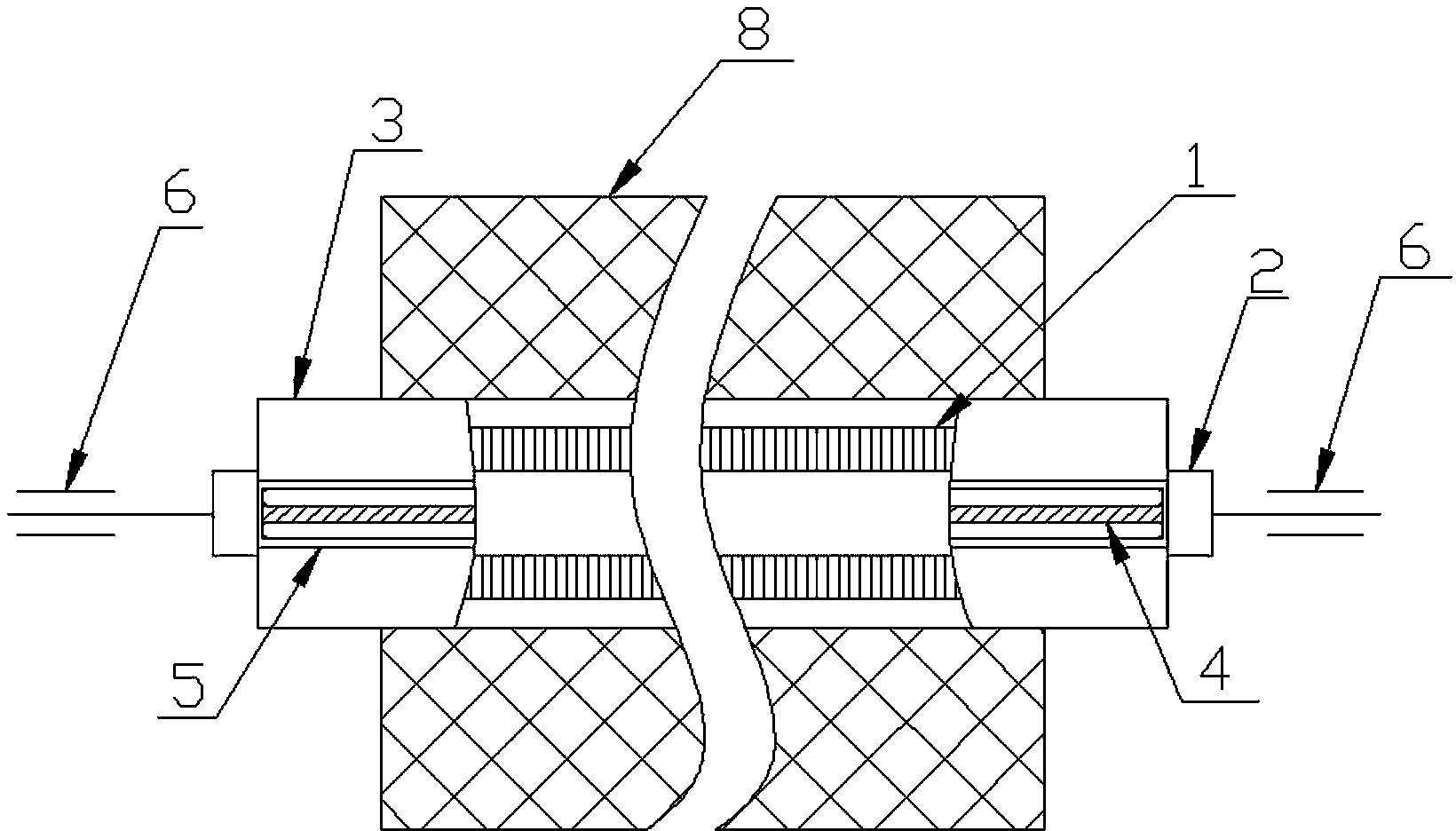

[0023] A device for cleaning the reverse side of the breathable mesh belt of a wood-based panel pre-pressing machine, comprising a brush 1, a roller 2, a shield 3, a paddle 4, an air suction port 5 and a bracket 7, and the brush 1 is arranged on the side of the roller 2 On the outer surface, the left and right ends of the roller 2 are respectively fixed on the bracket, the left and right ends of the shield 3 are fixed on the bracket, and the brush 1 and the roller 2 are wrapped, and the pick 4 is set In the middle of the air suction port 5, the left and right ends are fixed in the slots of the air suction port 5, the air suction port 5 is arranged in a vertical direction below the guard 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com