Mechanism for controlling flow directions of airflow and biomass burner using same

A technology of flow direction and airflow control, applied in combustion methods, combustion equipment, fuel supply, etc., can solve the problems of biomass burners not working normally, increasing maintenance costs and operating costs, hindering continuous production, etc., and achieving simple structure , low cost, convenient production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

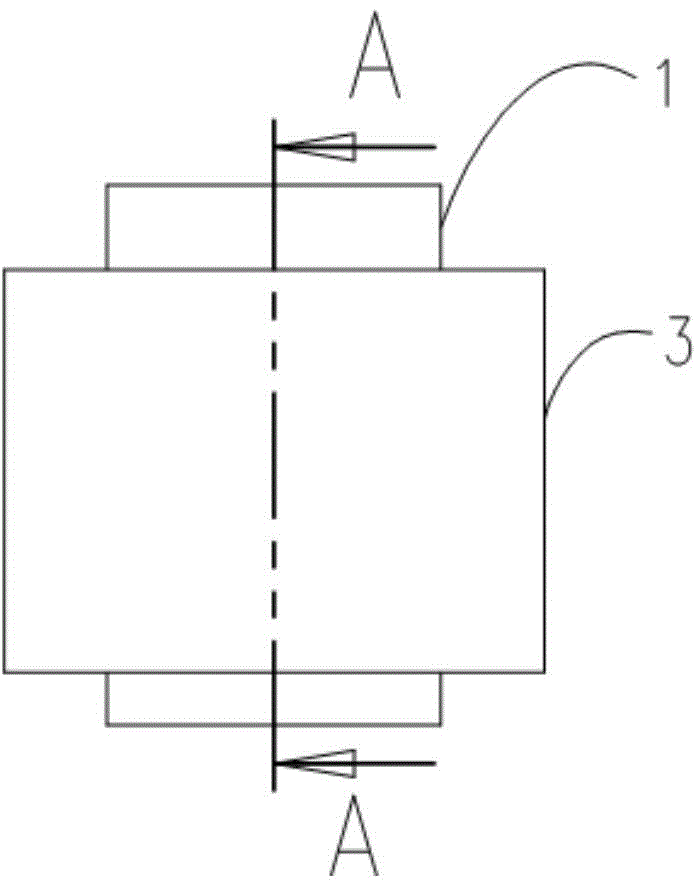

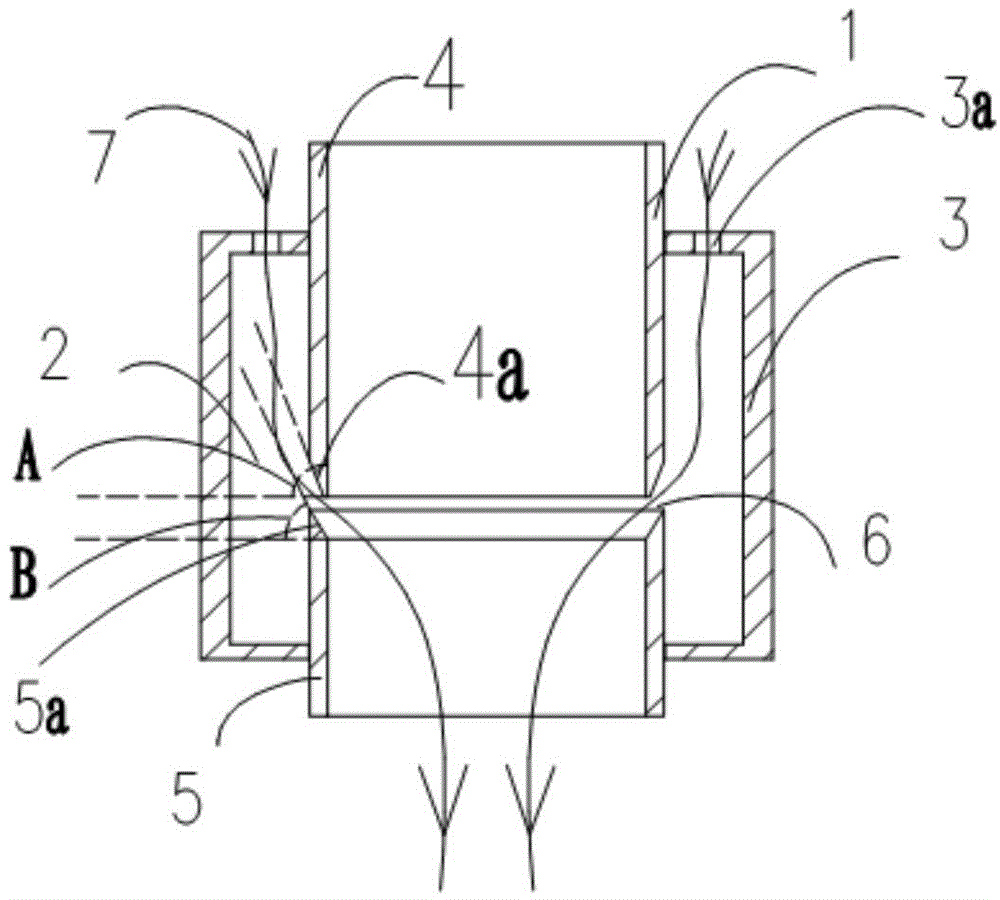

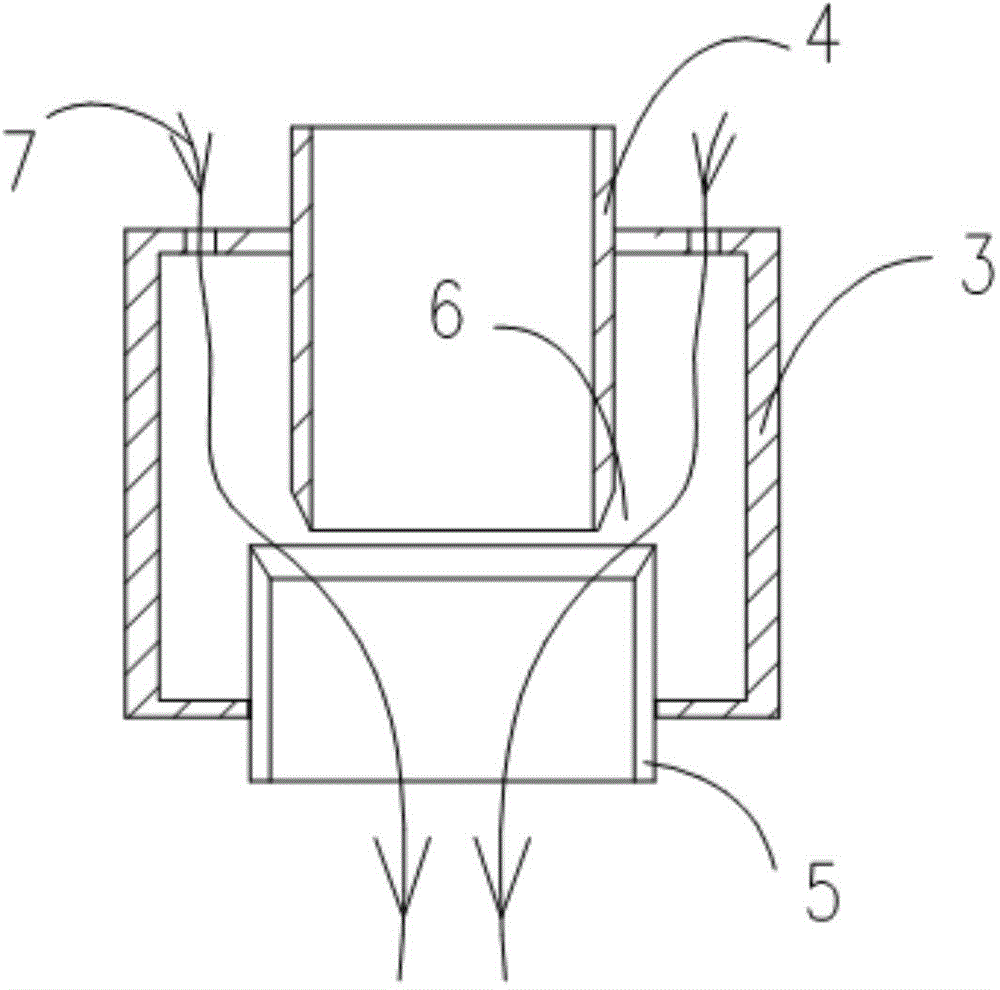

[0030] figure 1 It is a schematic diagram of the appearance of Embodiment 1 of a mechanism for controlling the flow direction of airflow in the present invention; figure 2 It is a schematic diagram of the internal structure of Embodiment 2 of a mechanism for controlling the flow direction of airflow in the present invention; figure 1 and figure 2 As shown, a mechanism for controlling the flow direction of airflow includes a cylinder 1 and a sleeve 3 arranged on the outer wall of the cylinder and forming a closed space 2 with the cylinder, and the cylinder 3 includes a first cylinder segment 4 and the second cylinder section 5 are two sections up and down, the two are coaxially arranged, and there is a distance 6 between the first cylinder section 4 and the second cylinder section 5; the first cylinder section 4 The outer wall near the end of the second cylindrical section 5 is provided with an outer chamfer 4a with a slope A; Chamfering 5a, an annular opening 6 is formed ...

Embodiment 2

[0033] image 3 It is a schematic diagram of the internal structure of Embodiment 2 of a mechanism for controlling the flow direction of airflow in the present invention; image 3 As shown, the outer diameter of the first cylindrical section 4 is D1, the outer diameter of the second cylindrical section 5 is D2, and D1=0.7*D2.

Embodiment 3

[0035] Figure 4 It is a schematic structural diagram of a biomass burner using the mechanism for controlling the flow direction of the airflow. Such as Figure 4 As shown, a biomass burner includes a silo 8, a screw feeder 9 connected to the bottom of the silo, and a feeding channel 10 connected to the outlet end of the screw feeder 9. The feeding channel 10 is connected to the combustion chamber. In the chamber 11, the combustion chamber 11 is also provided with a flame nozzle 11a, including the above-mentioned mechanism for controlling the flow direction of the airflow and the wind source 12. The mechanism for controlling the flow direction of the airflow is arranged at the outlet end of the screw feeder 9 and Between the feeding channels 10; the biomass particles sheared by the screw feeder 9 enter the cylinder 3, and the wind source 12 is introduced and blown in from the annular opening 6 to send the biomass particles into the feeding channel 10. Combustion in the combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com