An underwater mud-water separation device for test pools

A mud-water separation and test pool technology, applied in separation methods, filtration separation, water/sludge/sewage treatment, etc., can solve problems such as large equipment, and achieve the effects of convenient operation, improved work efficiency, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

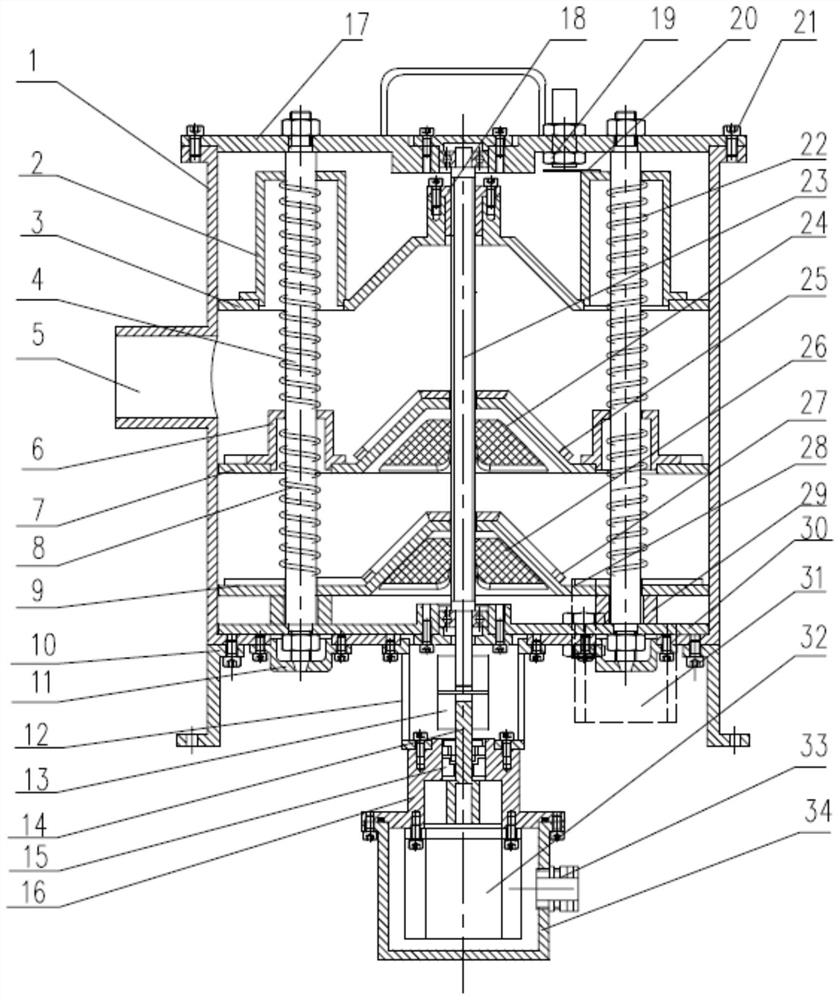

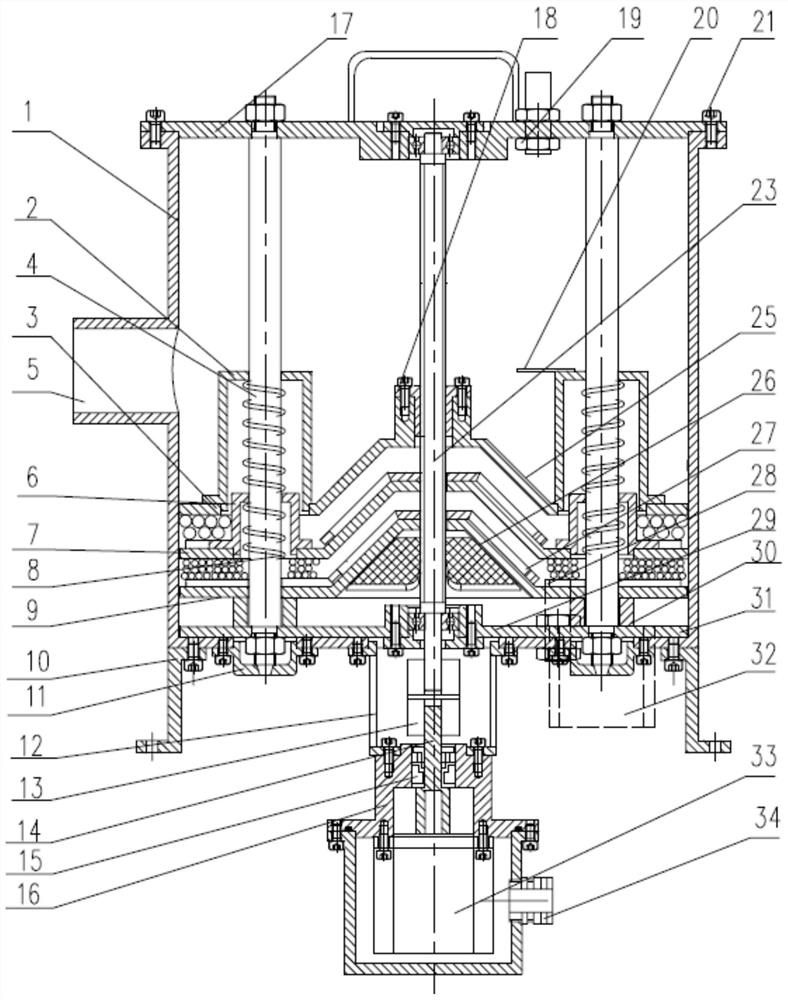

[0024] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0025] like figure 1 and figure 2 As shown, the underwater mud-water separation device for the test pool of this embodiment includes a filter cylinder 1, the top of the filter cylinder 1 is installed with an upper cover plate 17, the bottom is installed with a lower fixed plate 29, and the filter cylinder 1 is installed on the bottom. The bottom surface is supported by the support base 10; the fender 3, the coarse filter plate 7 and the fine filter plate 9 are installed in parallel and at intervals from top to bottom in the filter cylinder 1, and a lead screw 23 is installed in the middle of the filter cylinder 1, and the lead screw The guide rods 4 are respectively installed at both ends of the 23. The lead screw 23 and the guide rod 4 pass through the fender 3, the coarse filter plate 7 and the fine filter plate 9 in turn, and are on the lead scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com