Air-oxygen mixing structure for breathing machine and breathing machine

An oxygen mixing and ventilator technology, applied in the field of ventilators, can solve problems such as inaccurate detection, insufficient gas mixing, unstable pressure at the flow detection port, etc., achieve sufficient mixing, prevent turbulence from affecting flow detection, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

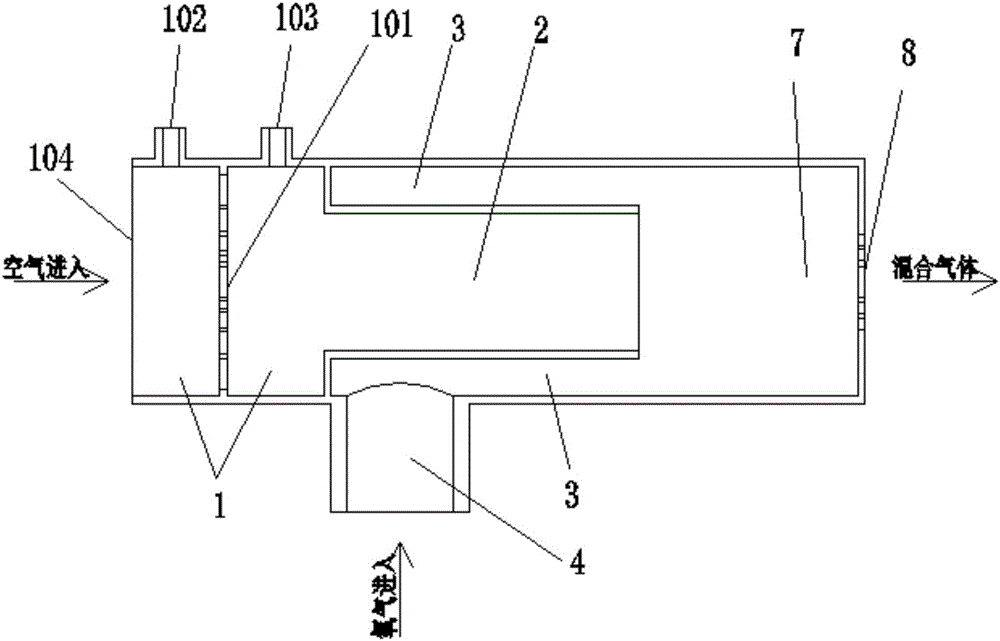

[0074] Such as figure 1 As shown, this embodiment provides an air-oxygen mixing structure for a ventilator, including:

[0075] Air flow detection chamber 1, air diversion chamber 2, oxygen diversion chamber 3, mixing chamber 7;

[0076] The inlet end of the air flow detection chamber 1 is an air inlet 104, and the outlet end of the air flow detection chamber 1 communicates with the inlet end of the air diversion chamber 2; the air flow detection chamber 1 is provided with a pressure drop perforated wall 101, and the pressure drop perforated wall The front and rear sides of 101 are respectively provided with flow detection port 1 102 and flow detection port 2 103;

[0077] The air guiding cavity 2 is a cylindrical cavity, the oxygen guiding cavity 3 is an annular cavity arranged on the periphery of the air guiding cavity 2, and the outer wall of the oxygen guiding cavity 3 is provided with an oxygen inlet 4; the air guiding cavity 2 and the outlet end of the oxygen guide ch...

Embodiment 2

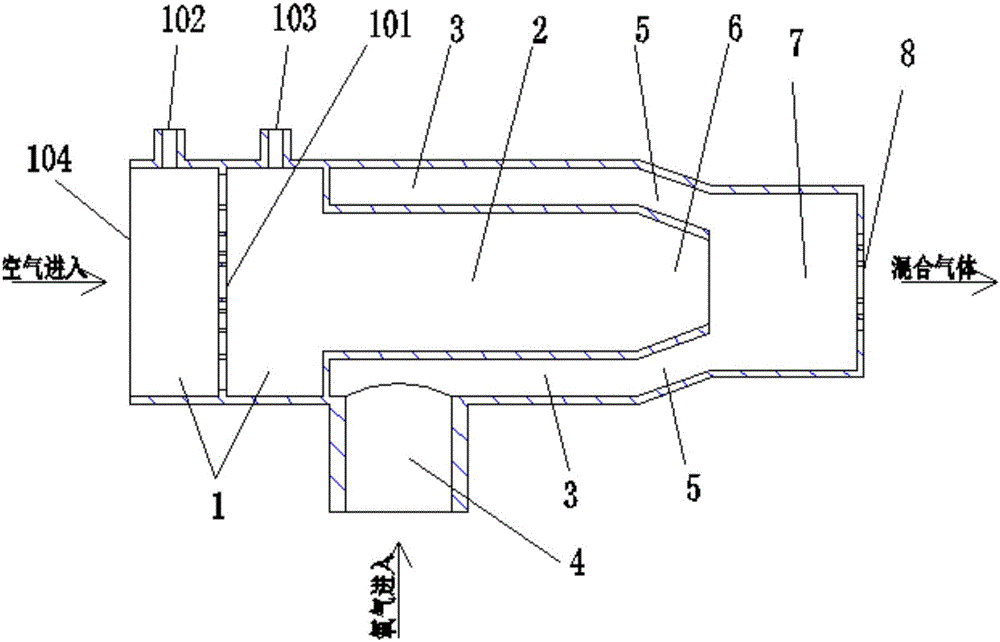

[0088] Such as figure 2 As shown, this embodiment provides an air-oxygen mixing structure for a ventilator, including:

[0089] Air flow detection chamber 1, air diversion chamber 2, oxygen diversion chamber 3, air mixing diversion chamber 6, oxygen mixing diversion chamber 5, mixing chamber 7;

[0090] The inlet end of the air flow detection chamber 1 is an air inlet 104, and the outlet end of the air flow detection chamber 1 communicates with the inlet end of the air diversion chamber 2; the air flow detection chamber 1 is provided with a pressure drop perforated wall 101, and the pressure drop perforated wall The front and rear sides of 101 are respectively provided with flow detection port 1 102 and flow detection port 2 103;

[0091] The air guiding cavity 2 is a cylindrical cavity, the oxygen guiding cavity 3 is an annular cavity arranged on the outer periphery of the air guiding cavity 2, and the outer wall of the oxygen guiding cavity 3 is provided with an oxygen inl...

Embodiment 3

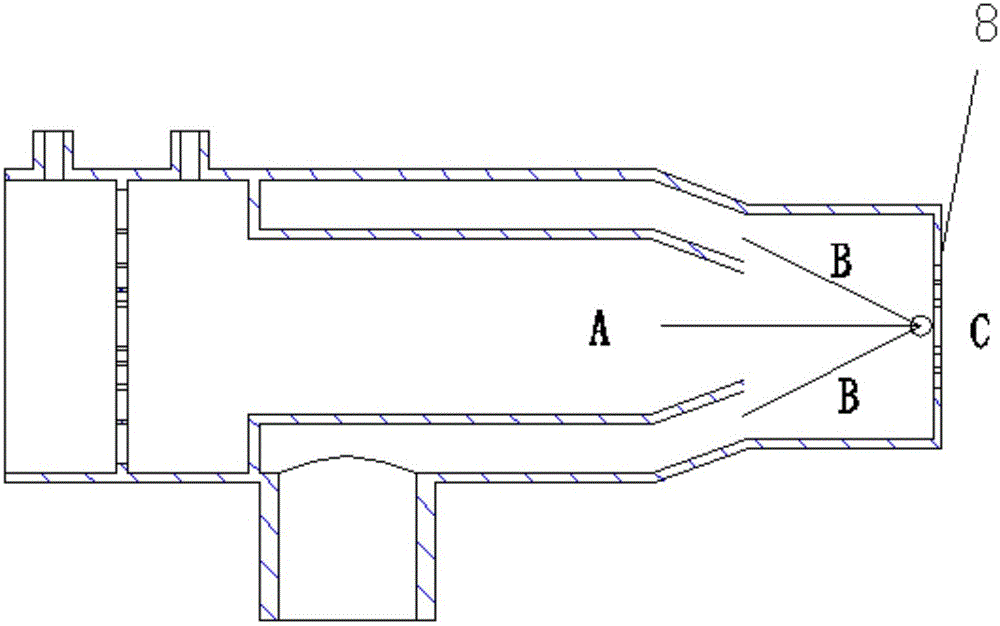

[0102] The difference between this embodiment and embodiment 2 is:

[0103] The cross-sectional area ratio of the oxygen guiding cavity 3 and the air guiding cavity 2 is 1:2;

[0104]The oxygen mixing diversion cavity 5 is inclined inwardly at an angle of 15°;

[0105] The total area of circular holes on the pressure drop perforated wall accounts for 50% of the area of the pressure drop perforated wall;

[0106] The total area of the circular holes on the mixed perforated wall 8 accounts for 60% of the area of the mixed perforated wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com