Elastic grinding head and grinding machine

An elastic grinding head and grinding machine technology, which is applied to the parts of grinding machine tools, grinding machines, abrasives, etc., can solve the problems of complicated steps in the process of removing sandpaper, deformation of grinding heads, shortening of service life, etc., and achieve quick replacement or removal. The effect of eliminating, reducing inhalation, and reducing the incidence of occupational diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

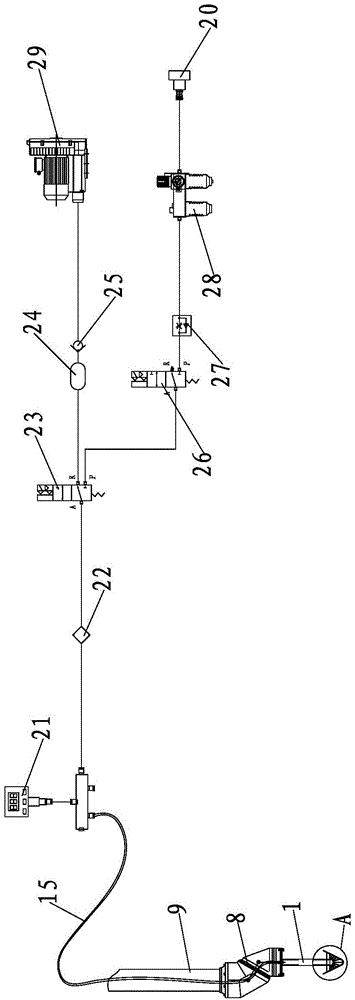

Method used

Image

Examples

Embodiment Construction

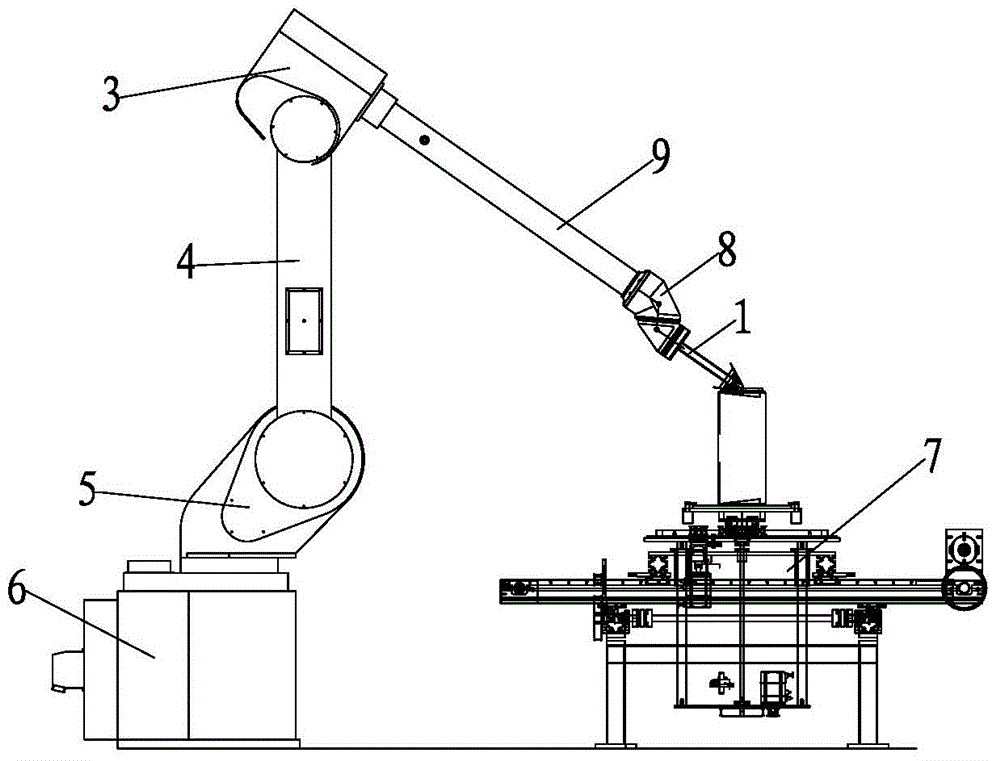

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

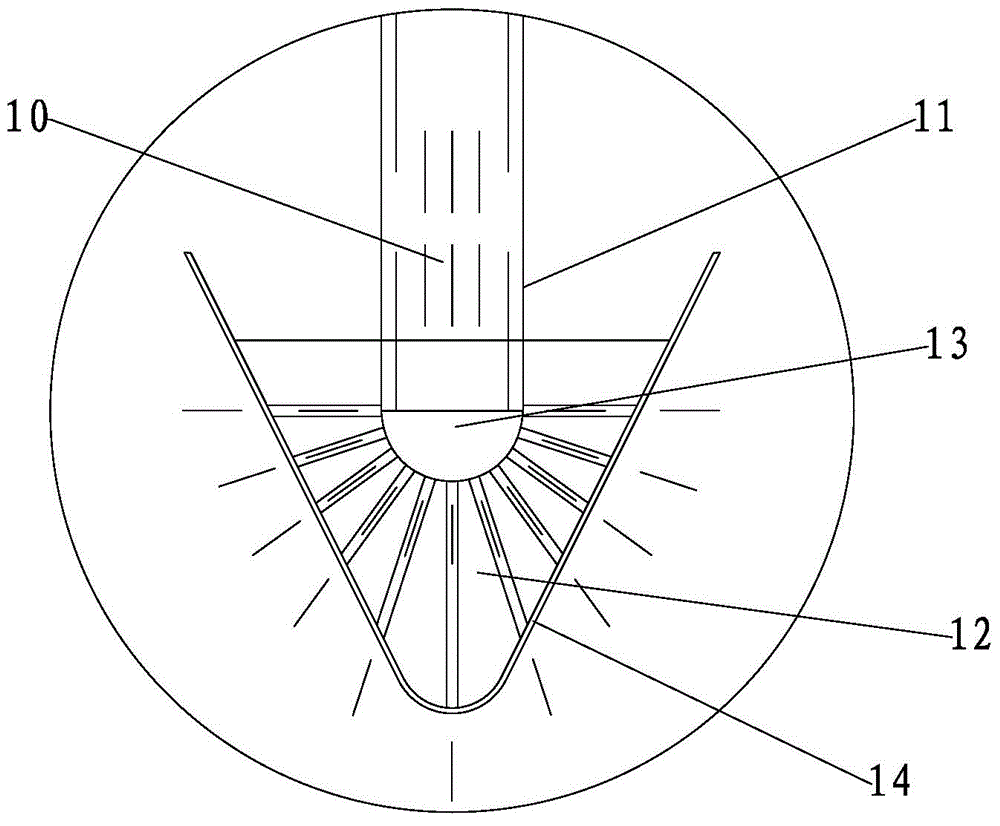

[0024] refer to figure 2 , an elastic grinding head 1, mainly used for grinding wood plastic products, including a vacuum rod 11, the vacuum rod 11 is provided with an inner cavity 10 along the length direction, and an elastic grinding head main body 12 is connected to the front end of the vacuum rod 11. The elastic A first through hole is opened on the grinding head main body 12 , the first through hole communicates with the inner chamber 10 of the vacuum rod 11 , and sandpaper 14 is arranged on the outer wall of the elastic grinding head main body 12 . In this embodiment, the elastic grinding head main body 12 is detachably connected to the front end of the vacuum rod 11 , and can be connected to the vacuum rod 11 by clamping, screwing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com