Intelligent detection system for Duty parameters of machine tool

A technology of working condition parameters and intelligent detection, which is applied in the direction of manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of failure to realize real-time monitoring, insufficient intelligence of the detection process, and increased management difficulty, etc., to achieve high versatility Sex and practical value, promotion of machine tool processing automation, strong compatibility and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific examples.

[0043] Main hardware part:

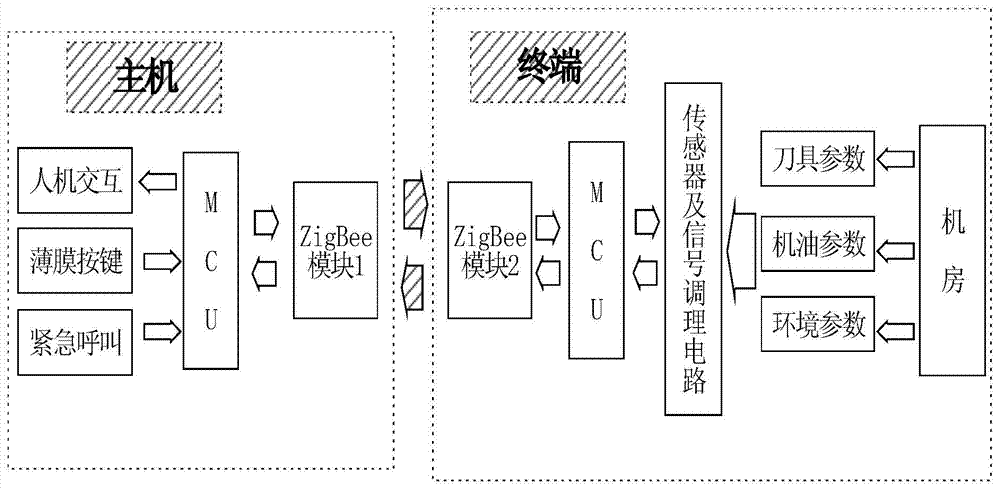

[0044] The detection system is designed as figure 1 As shown, the system includes two parts: the host and the terminal. The host is composed of MCU minimum system, ZigBee module 1, man-machine interface, membrane button circuit, and sound and light alarm circuit (emergency call). The terminal is composed of the minimum system of single-chip microcomputer, ZigBee module 2, tool parameter detection module, engine oil parameter detection module, and environmental parameter detection module. Among them, ZigBee module 1 and ZigBee module 2 adopt the same hardware circuit.

[0045] The system uses the stabilized power supply obtained by AC-DC conversion from the mains as the power supply for the system. The host sends corresponding control commands to the terminal through the ZigBee module 1 according to the requirements. After receiving the command,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com