Gear edge and corner grinding machine

A technology for grinding machines and gears, which is applied in the direction of belts/chains/gears, gear teeth, mechanical equipment, etc., which can solve problems such as low efficiency, poor adaptability to gear chamfering, and poor processing accuracy, and achieve high efficiency and good processing accuracy , good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

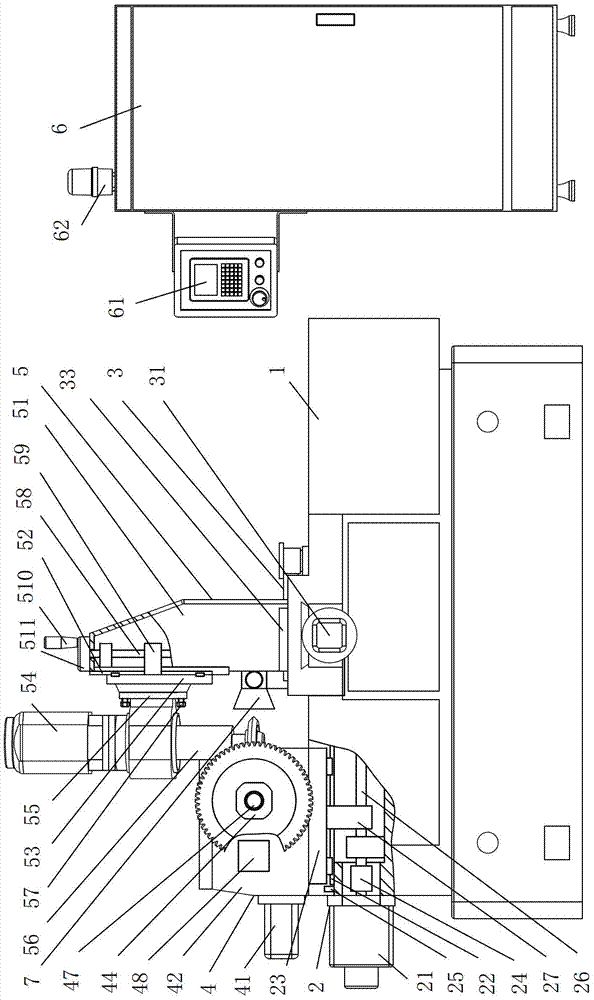

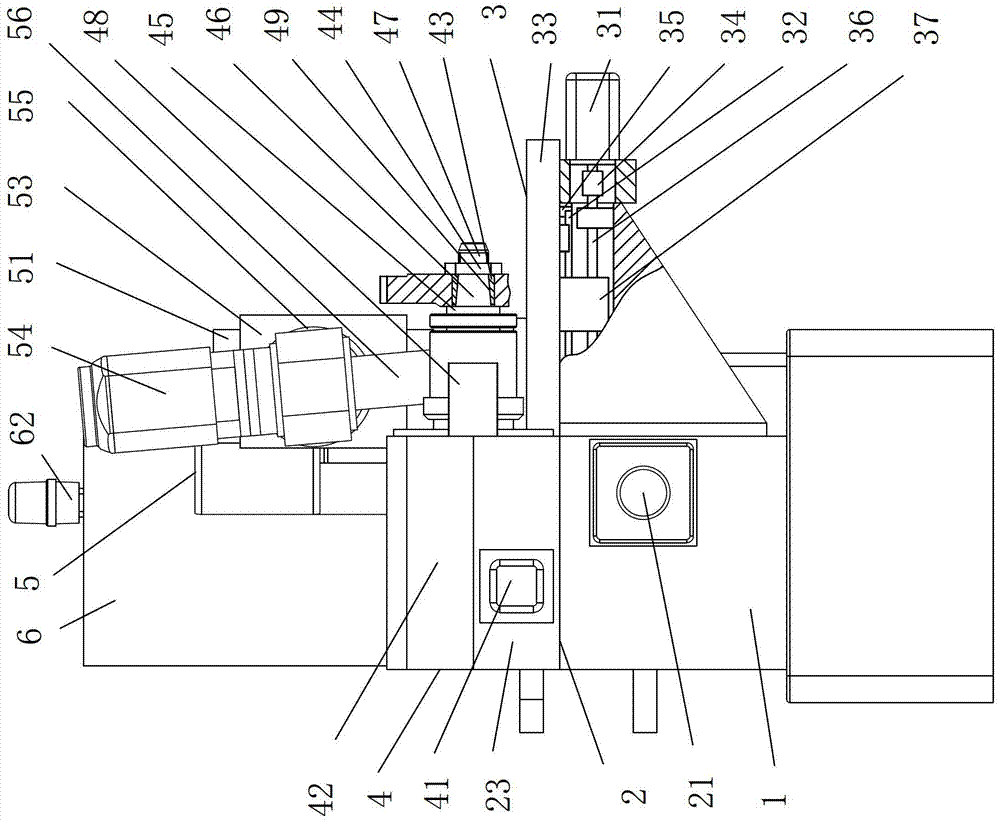

[0020] as attached figure 1 , attached figure 2 Shown: a gear edge grinding machine, including a base 1, an X-direction movement unit 2 and a Y-direction movement unit 3 respectively connected to the base 1, a gear positioning and rotating device 4 connected to the X-direction movement unit 2, and a Y-direction movement unit 4 connected to the Y-direction movement unit. The grinding device 5 and the controller 6 are connected to the movement unit 3 .

[0021] The X-direction motion unit 2 includes an X-direction servo motor 21 screwed to the base 1, an X-direction slide 23 connected to the base 1 through an X-direction linear guide 22, an X-direction ball screw, and an X-direction coupling 24 and two X-direction limit switches 25 that are opposite to one end of the X-direction slide seat 23 and are screwed to the base 1; the two ends of the X-direction screw 26 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com