A kind of preparation method of polysaccharide-based silver nanoparticles

A technology of silver nanoparticles and polysaccharides is applied in the field of preparation of silver nanoparticles to achieve the effects of good dispersion stability, continuous large-scale production and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The prepared mass concentration is 0.5mg / mL, carboxyl content is 2.07mmol / g oxidized Ketran polysaccharide solution is added to the molar concentration of 1mmol / L water-soluble silver nitrate solution to form a mixed solution; 100° C. for constant temperature reaction for 2 h, cooled to room temperature, filtered, centrifuged, dispersed, dialyzed and freeze-dried to obtain polysaccharide-based silver nanoparticles.

Embodiment 2

[0022] The prepared mass concentration is 2.0mg / mL, carboxyl content is 4.87mmol / g oxidized Ketran polysaccharide solution is added to the water-soluble silver nitrate solution with molar concentration of 100mmol / L to form a mixed solution; 100° C. for constant temperature reaction for 2 h, cooled to room temperature, filtered, centrifuged, dispersed, dialyzed and freeze-dried to obtain polysaccharide-based silver nanoparticles.

Embodiment 3

[0024] This example is basically the same as Example 1, except that the mass concentration of oxidized cotran polysaccharide is 1.0 mg / mL, the carboxyl content is 4.87 mmol / g, and the molar concentration of the water-soluble silver nitrate solution is 10 mmol / L.

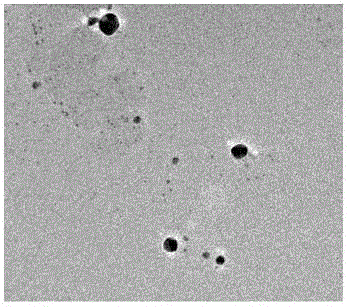

[0025] Disperse the above-mentioned silver nanoparticles prepared in distilled water to obtain a silver nanoparticle solution with a concentration of 0.5 mg / mL, and observe its TEM image, as shown in figure 1 As shown, the morphology of the silver nanoparticles is spherical, the particle size is uniform, and the average particle size is 15nm. Stored at room temperature for half a year without agglomeration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com