Micronano-structured and silver phosphate based composite visible light catalytic material and preparing method thereof

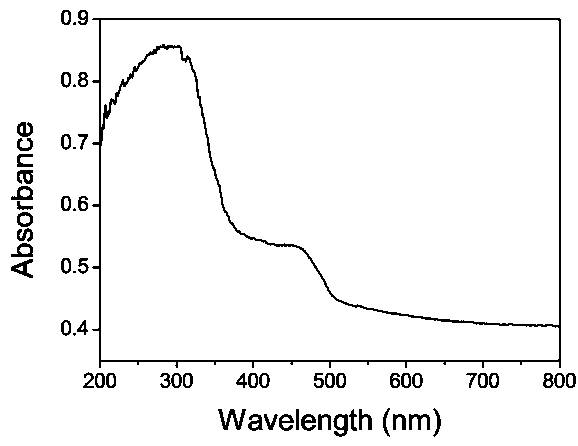

A catalytic material, silver phosphate-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of accelerating the separation of photogenerated electron pairs, small size, etc., and achieve energy saving and environmental protection performance, high light Effects of Energy Utilization and Wide Visible Light Response Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

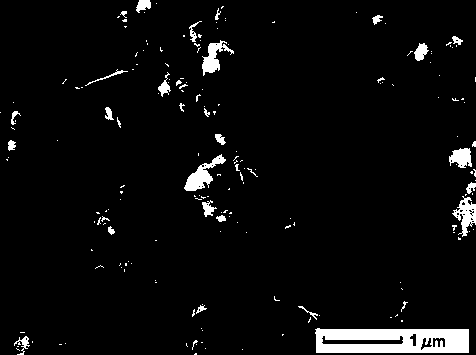

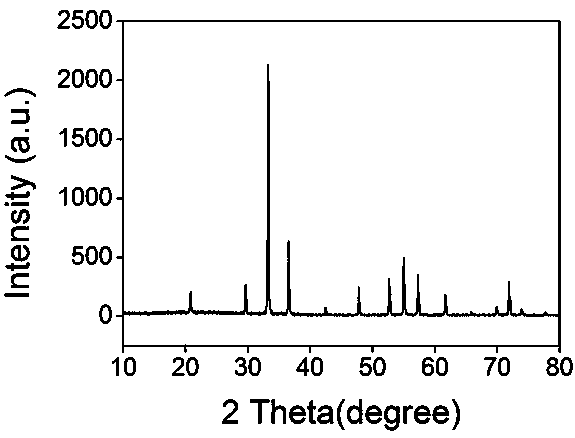

[0026] Disperse 10 mg of graphene oxide in 50 ml of deionized water and sonicate for 5 hours to obtain a graphene oxide dispersion, weigh 1.529 g of silver nitrate and 200 mg of ZnO and dissolve them in 50 ml of deionized water for 30 minutes to obtain a mixed precursor solution A, Add the mixed precursor solution A dropwise to the above graphene oxide dispersion under magnetic stirring, and continue to stir at a speed of 100 rpm at room temperature for 6 hours to obtain the mixed precursor solution B; weigh 0.426 g Na 2 HPO 4 The solid was dissolved in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution, and the prepared disodium hydrogen phosphate solution was added dropwise to the mixed precursor solution B under agitation until gray-green turbidity appeared in the reaction system, and the addition was completed The resulting mixed solution was continuously stirred at a speed of 200 rpm for 30 min, and the obtained product was filtered with suction, wa...

Embodiment 2

[0028] Disperse 20 mg of graphene oxide in 50 ml of deionized water and sonicate for 5 hours to obtain a graphene oxide dispersion; weigh 1.529 g of silver nitrate and 300 mg of ZnO in 50 ml of deionized water and sonicate for 30 min to obtain a mixed precursor solution A; Add the mixed precursor solution A dropwise to the above graphene oxide dispersion under magnetic stirring, and continue to stir at a speed of 100 rpm at room temperature for 8 hours to obtain the mixed precursor solution B; weigh 0.426 g Na 2 HPO 4 The solid was dissolved in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution, and the prepared disodium hydrogen phosphate solution was added dropwise to the mixed precursor solution B under agitation until gray-green turbidity appeared in the reaction system, and the addition was completed The resulting mixed solution was continuously stirred at a speed of 200 rpm for 40 min, and the obtained product was filtered with suction, washed with...

Embodiment 3

[0030] Disperse 50 mg of graphene oxide in 50 ml of deionized water and sonicate for 5 hours to obtain a graphene oxide dispersion, weigh 1.529 g of silver nitrate and 400 mg of ZnO and dissolve them in 50 ml of deionized water for 30 minutes to obtain a mixed precursor solution A, Add the mixed precursor solution A dropwise to the above graphene oxide dispersion under magnetic stirring, and continue to stir at a speed of 100 rpm at room temperature for 10 hours to obtain the mixed precursor solution B; weigh 0.426 g Na 2 HPO 4 The solid was dissolved in 20 ml of deionized water to obtain a disodium hydrogen phosphate solution, and the prepared disodium hydrogen phosphate solution was added dropwise to the mixed precursor solution B under stirring conditions until gray-green turbidity appeared in the reaction system, and the addition was completed The resulting mixed solution was continuously stirred at a speed of 200 rpm for 50 min, and the obtained product was filtered with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com