Quick-release zipper with top stop assembly and clothing using the zipper

A stopper and zipper technology, applied in the field of quick-off clothes, can solve the problems of being easily stuck, the zipper head cannot be effectively locked, and easy to rust and oxidize, so as to achieve the effect of wearing trousers quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

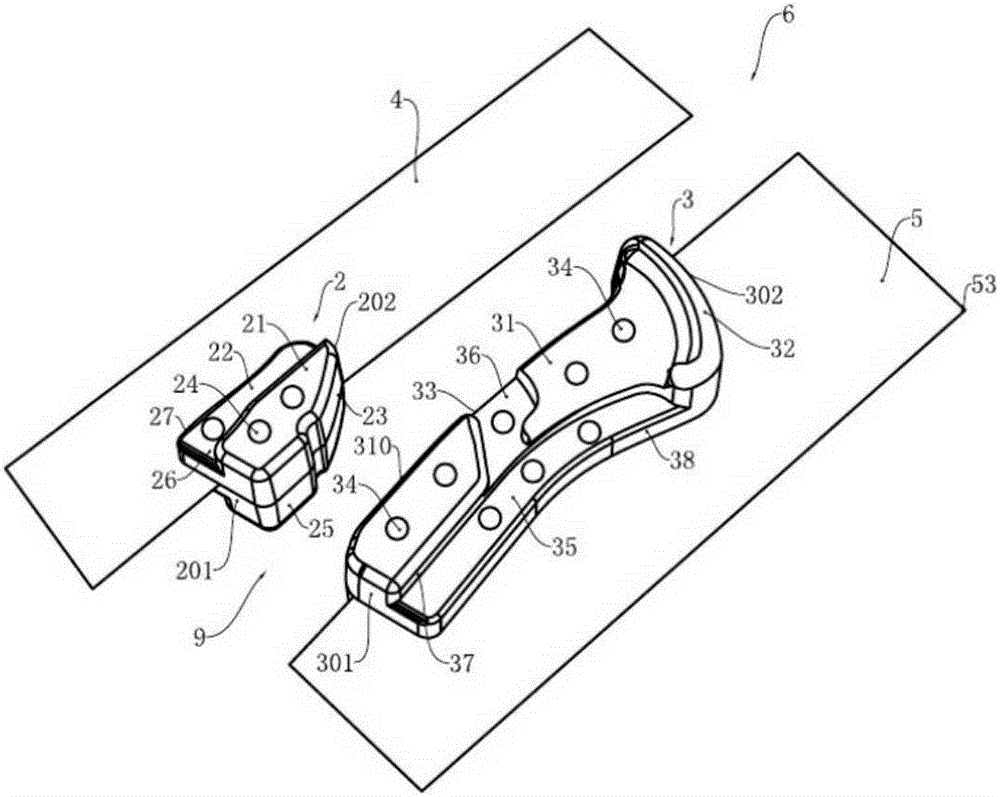

[0042] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0043] Such as figure 1 Shown is a schematic structural view of the slider 1 used in conjunction with the top stop assembly 9 . Wherein the slider 1 includes an upper cover 11, a lower cover 12, and an intermediate connecting column 13, the upper cover 11 is provided with a pull piece 16, and there is a sprocket passing between the upper cover 11 and the lower cover 12. Groove 14 and sprocket inlet and outlet, the front end of the slider 1 is the sprocket outlet end 15, and its tail end is the sprocket inlet end 10, between the sprocket outlet end 15 and the sprocket inlet end 10 The channel is sprocket through slot 14.

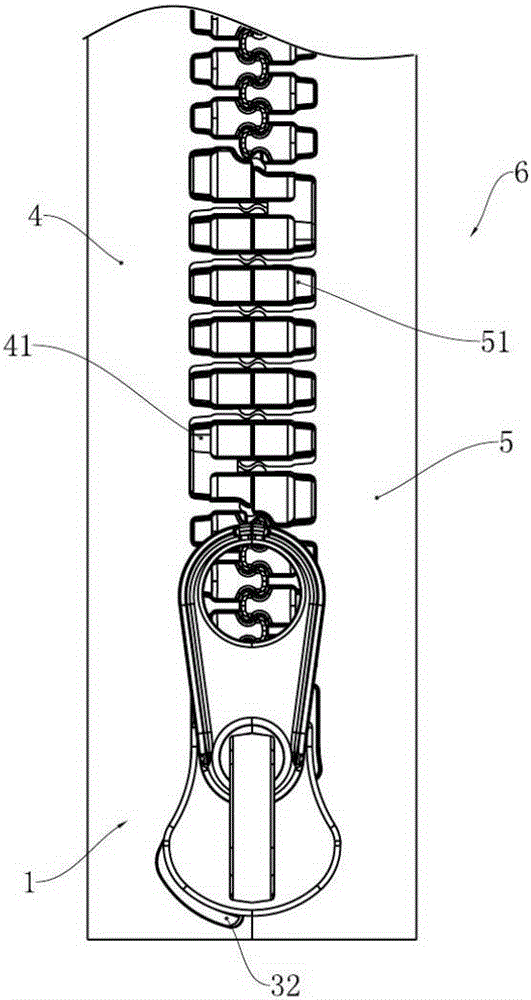

[0044] image 3 As shown, when the slider 1 is pulled downward, the chain teeth (41, 51) of the zipper 6 enter through the entrance of the entrance end 10 of the chain teeth and enter the entrances of the two sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com