Method of seasoning grilling mutton chops

A technology for conditioning barbecue and lamb chops, applied in the functions of food ingredients, food ingredients as antioxidants, food preparation, etc., can solve problems such as single taste, and achieve the effects of multi-selectivity, attractive taste and rich variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

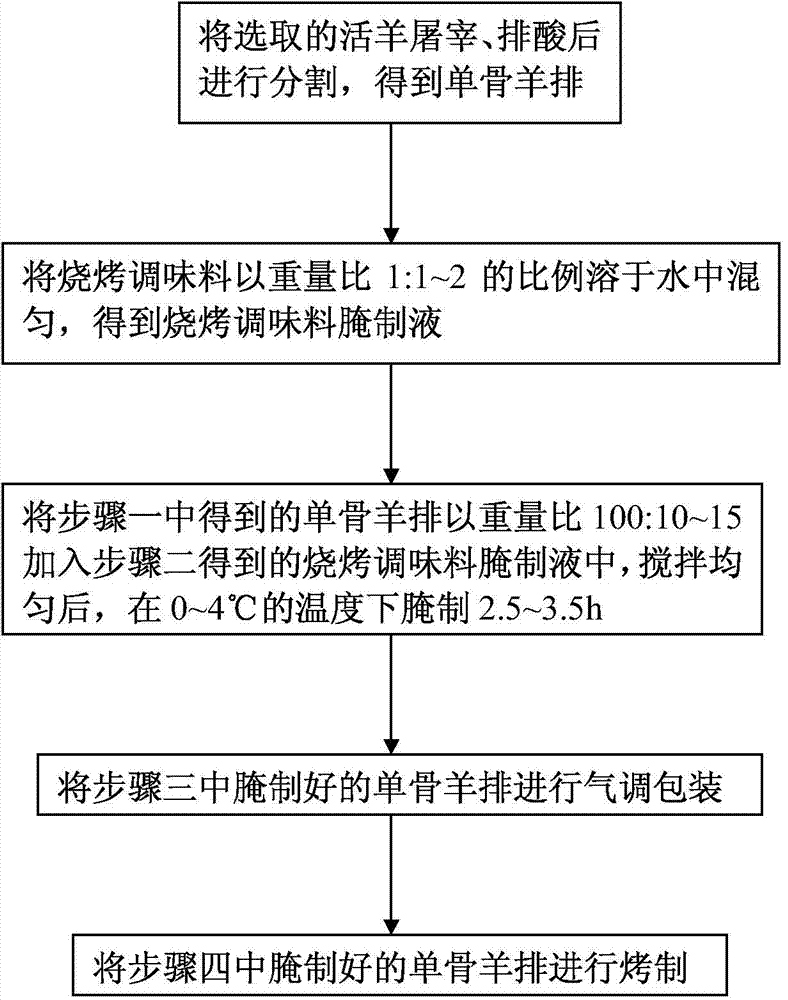

Method used

Image

Examples

Embodiment 1

[0057] A method of conditioning grilled lamb chops, comprising:

[0058] Step 1: Slaughter the selected live sheep, deacidify them for 24 hours, and divide them to obtain single-bone lamb chops;

[0059] Step 2. Dissolve the prepared black pepper flavor powder barbecue seasoning in water at a weight ratio of 1:1 and mix evenly to obtain black pepper flavor powder barbecue seasoning marinade, black pepper flavor powder barbecue seasoning formula raw material quality The servings are as follows:

[0060] 24 parts of table salt, 8 parts of monosodium glutamate, 32 parts of white sugar, 0.4 parts of I+G, 4 parts of compound phosphate, 4 parts of thirteen spices, 3 parts of chili powder, 3 parts of green onion powder, 3 parts of garlic powder, white pepper powder 2 parts, 12 parts of crushed black pepper, 3 parts of corn starch, 0.3 parts of bamboo leaf extract, 0.02 parts of papain, 0.28 parts of capsanthin, 0.8 parts of nisin, 0.2 parts of ethyl maltol;

[0061] Step 3. Add the...

Embodiment 2

[0065] A method of conditioning grilled lamb chops, comprising:

[0066] Step 1: Slaughter the selected live sheep, deacidify them for 24 hours, and divide them to obtain single-bone lamb chops;

[0067] Step 2. Dissolve the prepared cumin flavor powder barbecue seasoning in water at a weight ratio of 1:1 and mix evenly to obtain the cumin flavor powder barbecue seasoning marinade. The raw material quality of the cumin flavor powder barbecue seasoning formula is The servings are as follows:

[0068] 24 parts of table salt, 8 parts of monosodium glutamate, 32 parts of white sugar, 0.4 parts of I+G, 4 parts of compound phosphate, 4 parts of thirteen spices, 3 parts of chili powder, 8 parts of cumin powder, 3 parts of green onion powder, garlic powder 3 parts, white pepper powder 2 parts, corn starch 7 parts, bamboo leaf extract 0.3 parts, papain 0.02 parts, capsanthin 0.28 parts, nisin 0.8 parts, ethyl maltol 0.2 parts.

[0069] Step 3. Add the single-bone lamb chops obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com