Device having a heat exchanger for a thermoelectric generator of a motor vehicle

A technology for heat exchangers and internal combustion engines, which is used in heat exchange equipment, thermoelectric devices that only use the Peltier or Seebeck effect, and heat exchangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

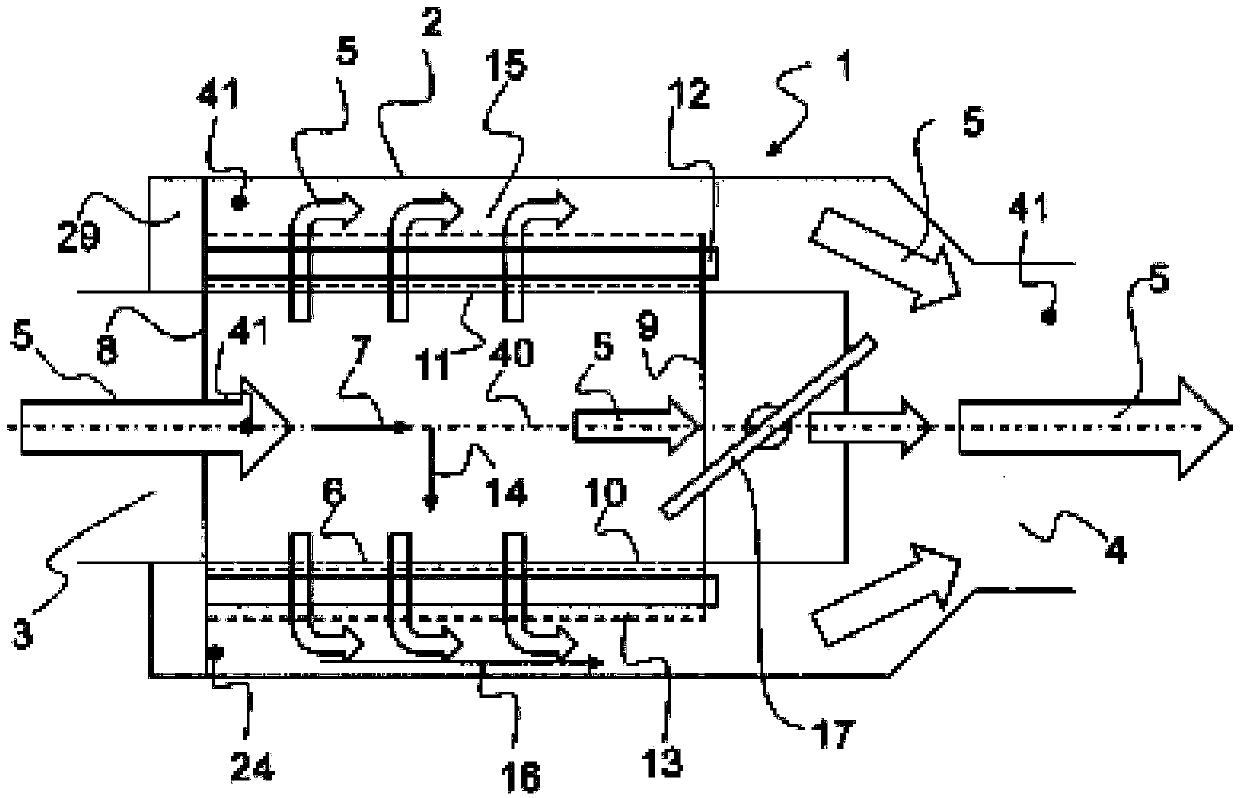

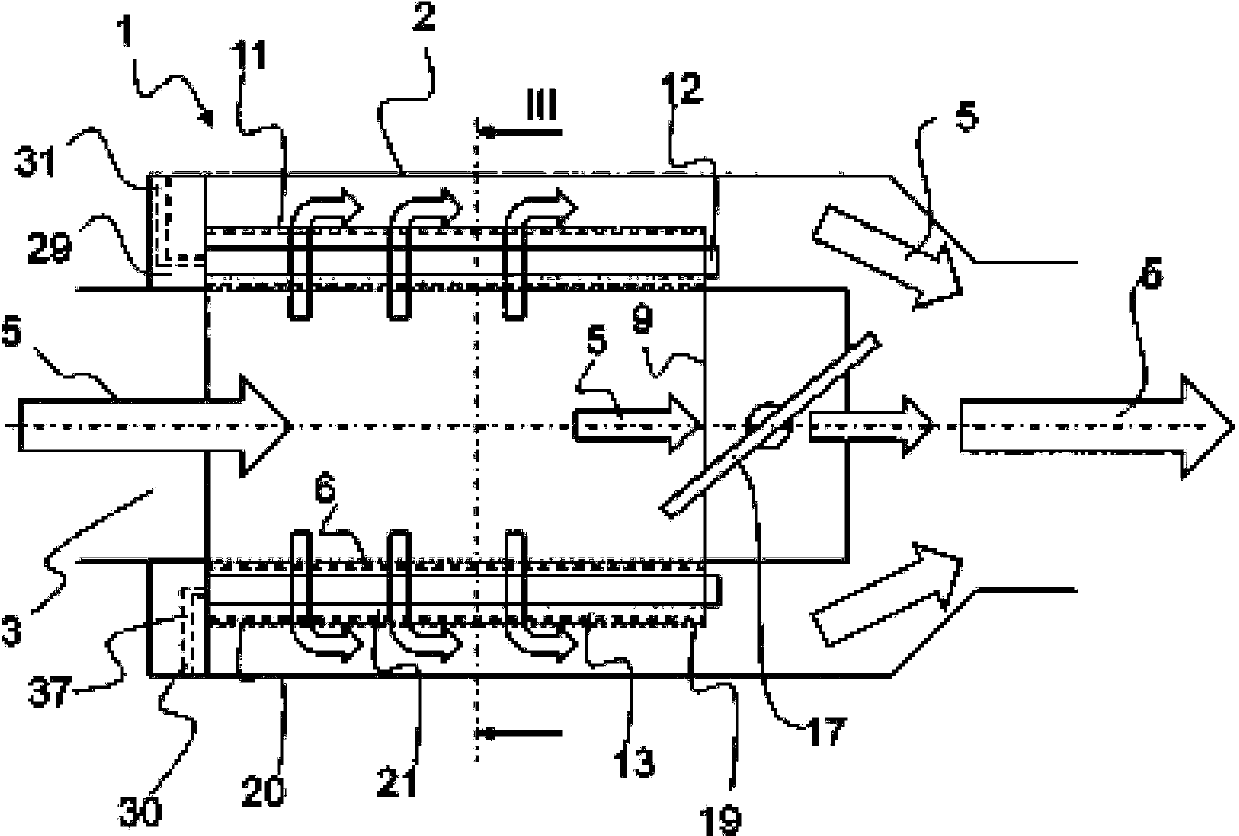

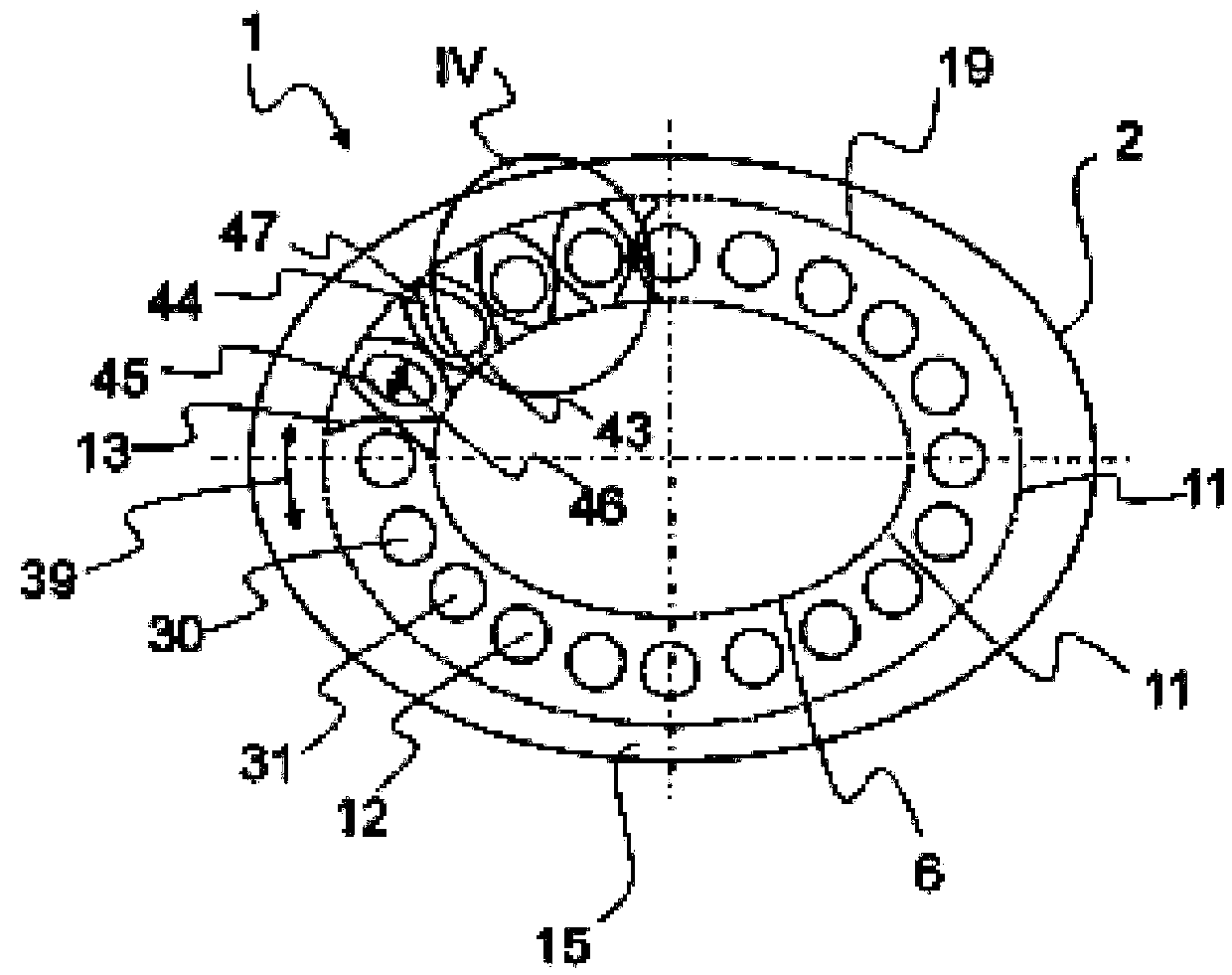

[0044] figure 1 The longitudinal section of the heat exchanger 1 is shown. The fluid 5 (or exhaust gas) flows through the inlet 3 in the axial direction 7 and flows into the inner pipe 6 of the heat exchanger 1 through the first end side 8 which is fluidly connected to the inlet 3. Here, the fluid flow is at least partially deflected, so that the fluid 5 then flows in the radial direction 14 in the direction of the first circumferential surface 10 of the inner pipe 6. The fluid 5 passes through the first circumferential surface 10 through the opening 11 and impinges on the heat exchanger tube 12 arranged at the outer side of the first circumferential surface 10. A guide part 13 is arranged between the heat exchanger tubes 12, which guides the fluid 5 around the heat exchanger tube 12. The fluid 5 flowing in the radial direction 14 enters the outflow pipe 15 which surrounds the heat exchanger pipe 12 on the outside and is bounded by the housing 2 on its own outside. Here, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com