Vinyl chloride resin composition for injection molding

A vinyl chloride resin, injection molding technology, applied in the field of vinyl chloride resin composition for injection molding, can solve the problems of poor gloss, unsatisfactory heat resistance of stabilizer, poor surface, etc., and achieves injection molding processability Excellent, no appearance defects, excellent thermal stability and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

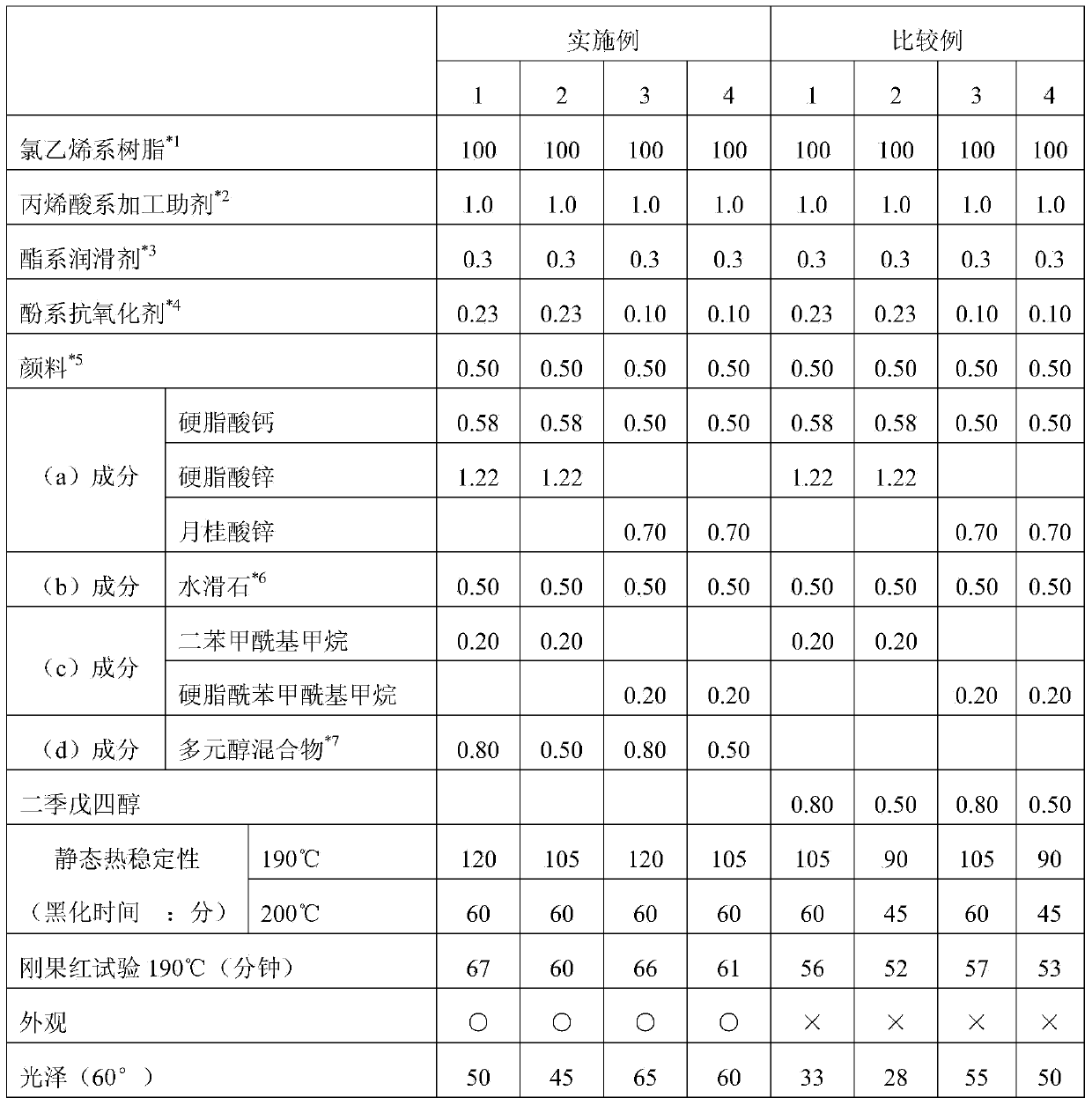

Embodiment 1~4 and comparative example 1~4

[0084]

[0085] The complexes in Table 1 below were stirred at 2000 rpm using a 10 L Henschel mixer, and the temperature was raised to 120°C. After reaching 120° C., it was cooled to 50° C. at 1000 rpm to obtain a compound for injection molding test.

[0086]

[0087] The obtained compound was injection-molded using an injection molding machine EC60NII manufactured by Toshiba Machine Co., Ltd. under the following conditions to obtain a cup-shaped molded body.

[0088] Injection molding conditions:

[0089] Cylinder temperature is 170~200℃

[0090] The injection pressure is 90~95MPa

[0091] Mold temperature is 40°C

[0092] The appearance of the obtained molded body was confirmed visually. Regarding the evaluation of the appearance, the case with burrs (surface defect) was evaluated as x, and the case without burrs was evaluated as ◯. The results are shown in Table 1. In addition, the gloss of the surface of the molded article was measured using a gloss meter (VG-200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com