Loudspeaker vibration system

A vibration system and loudspeaker technology, applied in the direction of sensors, transducer diaphragms, electromechanical sensors, etc., can solve the problems that cannot fully meet the requirements of high acoustic performance of products, and cannot meet the technical requirements of low f0 of products, and achieve Improve the acoustic performance, improve the sound effect, and reduce the effect of f0

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

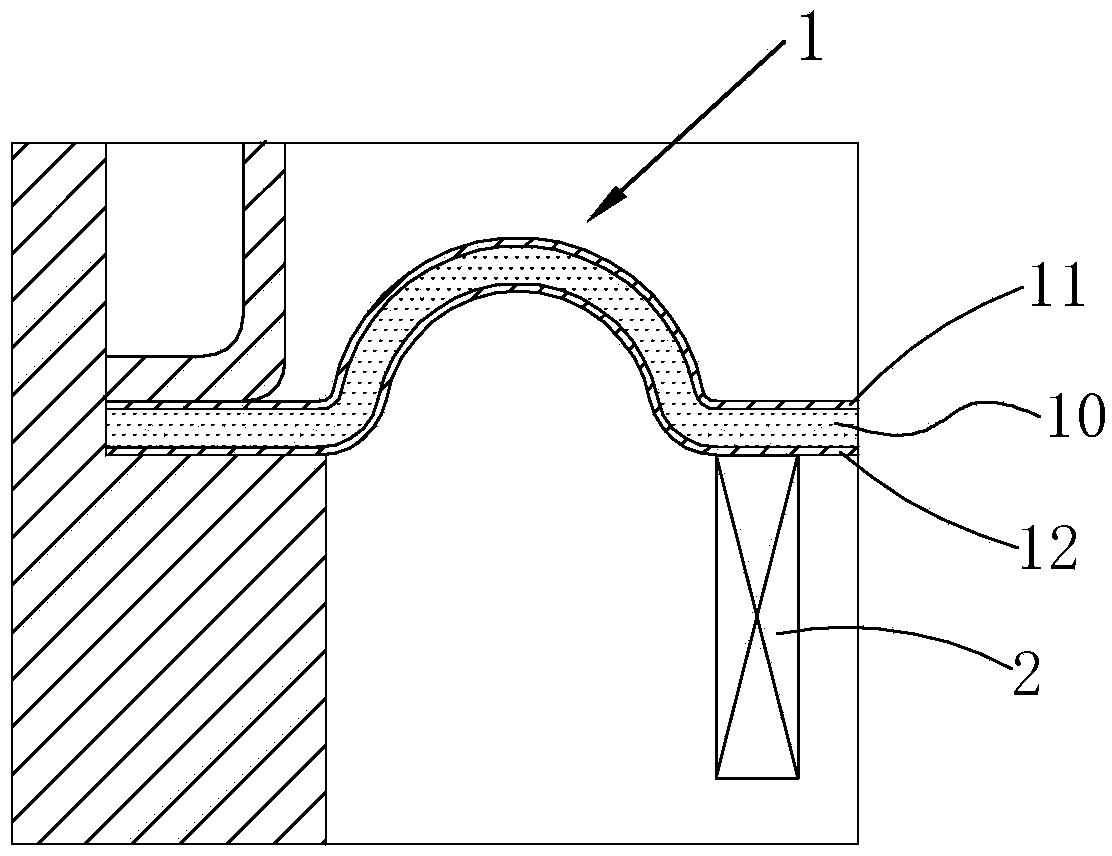

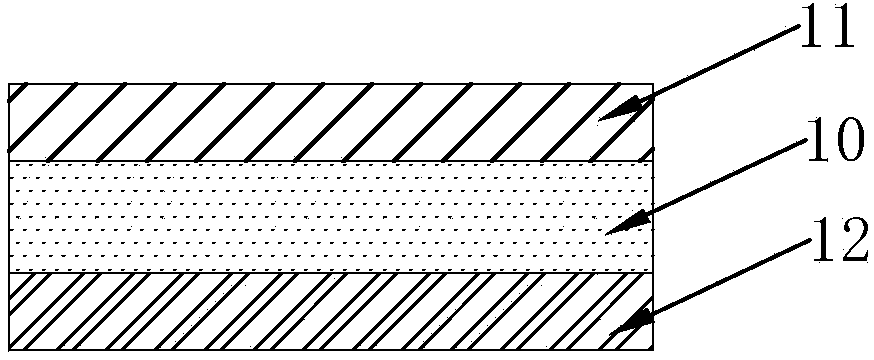

[0022] Such as figure 1 and figure 2 As shown, the speaker vibration system includes a diaphragm 1 and a voice coil 2 combined with one side of the diaphragm 1. The voice coil 2 vibrates up and down in the magnetic gap formed by the magnetic circuit system of the speaker after being connected to an electric signal. The vibration of the voice coil 2 It can simultaneously drive the diaphragm to vibrate to produce sound. Some characteristics of the vibrating membrane 1, including rigidity, material, etc., will affect the effect of the sound produced by its vibration. The diaphragm of this embodiment is composed of at least two layers of polyetheretherketone (PEEK) material base film. PEEK has rigidity and flexibility, outstanding fatigue resistance, high tensile strength, and good durability. High temperature / low temperature characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com