Novel steel-structure groove type cable bridge and processing equipment thereof

A technology of cable tray and processing equipment, applied in the direction of mechanical equipment, pipe supports, pipes/pipe joints/pipes, etc., can solve the problems of increasing the production cost of grooved cable trays, adding mounting brackets or hangers, and saving installation costs. , the effect of increasing the overall strength and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

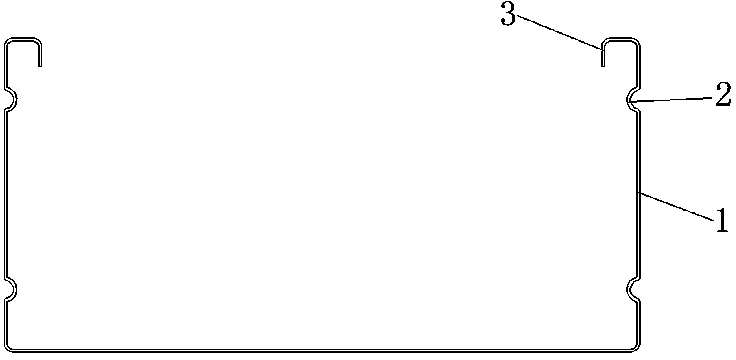

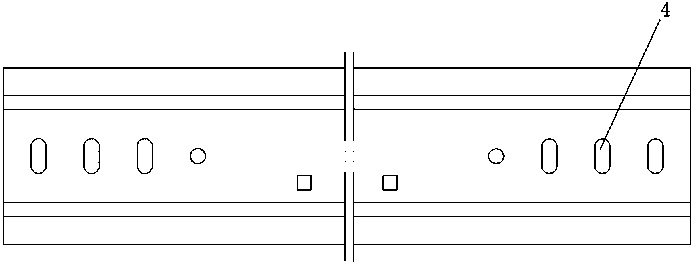

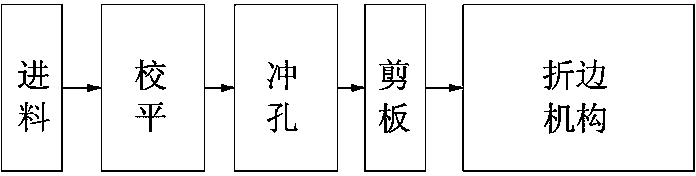

[0025] Such as figure 1 , 2 As shown, the trough body of the trough-type cable tray is a U-shaped long trough folded from a whole piece of steel plate. There are connection holes 4 on the side plates 1 at both ends of the trough body. The connection holes include 3 connection holes and 1 grounding wire Hole, a seven-character buttonhole on the cover plate, two raised ribs 2 are pressed along the length direction on the two side plates 1 of the tank body, and a 180-degree fold is folded inward along the length direction on the upper end of the two side plates. Side 3, so that the overall strength of the tank can be effectively increased on the basis of a certain plate thickness.

[0026] According to the size of the cross-section of the tank, the number of raised ribs on both sides can be adjusted. When the height of the tank is less than or equal to 100mm, the number of raised ribs is 2. When the height of the tank is greater than or equal to 150mm , the number of raised rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com