Antimicrobial and mildewproof paint and preparation method thereof

An antibacterial, antifungal and coating technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. Direct-contact, long-lasting, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

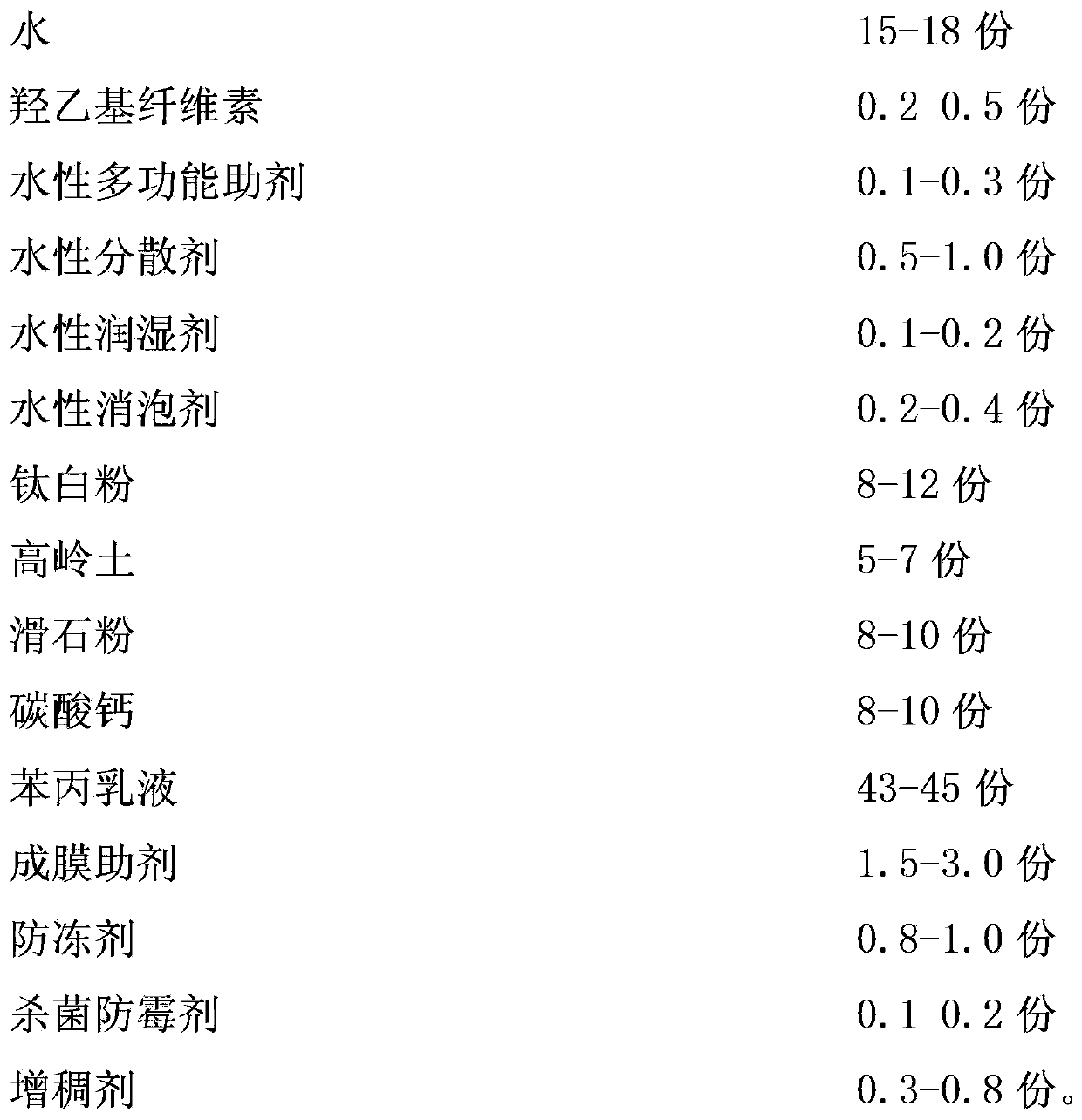

[0033] The preparation method of above-mentioned antibacterial antifungal paint, it comprises the following steps of carrying out in sequence:

[0034] (1) Add 15-18 parts of water into the dispersing tank, add 0.2-0.5 parts of hydroxyethyl cellulose and 0.1-0.3 parts of water-based multifunctional additives in turn under the stirring state of 350-550r / min, and stir for 1min-3min;

[0035] (2) After increasing the speed to 800-1000r / min, add 0.5-1.0 parts of water-based dispersant, 0.1-0.2 parts of water-based wetting agent, 0.2-0.4 parts of water-based defoamer, 8-12 parts of titanium dioxide, 5- After 7 parts of kaolin, 8-10 parts of talcum powder and 8-10 parts of calcium carbonate, increase the speed again to 1800-2000r / min and disperse for 15min-20min, then check whether the fineness is ≤60, if the fineness is ≤60, continue Execute step (3);

[0036] (3) Add 43-45 parts of styrene-acrylic emulsion, 1.5-3.0 parts of film-forming aids, 0.8-1.0 parts of antifreeze, 0.1-0.2 ...

Embodiment 1

[0038] Embodiment 1 is the best embodiment

[0039] A kind of antibacterial antifungal paint, it is made of the raw material of following weight ratio:

[0040]

[0041] The preparation method of above-mentioned antibacterial antifungal paint, it comprises the following steps of carrying out in sequence:

[0042] (1) Add 17.7 parts of water into the dispersing tank, add 0.3 parts of hydroxyethyl cellulose and 0.2 parts of water-based multifunctional additives in sequence under stirring at 400r / min, and stir for 1 minute;

[0043] (2) After increasing the rotation speed to 800r / min, add 0.6 parts of water-based dispersant, 0.1 part of water-based wetting agent, 0.4 parts of water-based defoamer, 12 parts of titanium dioxide, 5 parts of kaolin, 8 parts of talc and 8 parts of carbonic acid After calcium, increase the speed again to 1800r / min and disperse for 15 minutes, then check whether the fineness is ≤60, if the fineness is ≤60, continue to step (3);

[0044] (3) Add 44 ...

Embodiment 2

[0046] A kind of antibacterial antifungal paint, it is made of the raw material of following weight ratio:

[0047]

[0048] The preparation method of above-mentioned antibacterial antifungal paint, it comprises the following steps of carrying out in sequence:

[0049] (1) Add 18 parts of water into the dispersing tank, add 0.5 parts of hydroxyethyl cellulose and 0.3 parts of water-based multifunctional additives in sequence under stirring at 350r / min, and stir for 3 minutes;

[0050](2) After increasing the speed to 800r / min, add 1 part of water-based dispersant, 0.1 part of water-based wetting agent, 0.2 part of water-based defoamer, 8 parts of titanium dioxide, 5 parts of kaolin, 8 parts of talc and 8 parts of carbonic acid After calcium, increase the speed again to 2000r / min and disperse for 20 minutes, then check whether the fineness is ≤60, if the fineness is ≤60, continue to step (3);

[0051] (3) Add 45 parts of styrene-acrylic emulsion, 3.0 parts of film-forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com