Compound thermal insulation material manufactured by using waste fibers and manufacturing method thereof

A composite thermal insulation material and waste fiber technology, applied in the field of processing and manufacturing of composite thermal insulation materials, can solve the problems of poor thermal insulation effect, poor ablation resistance, energy consumption, etc., and achieve the effects of improving product quality, ensuring purity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

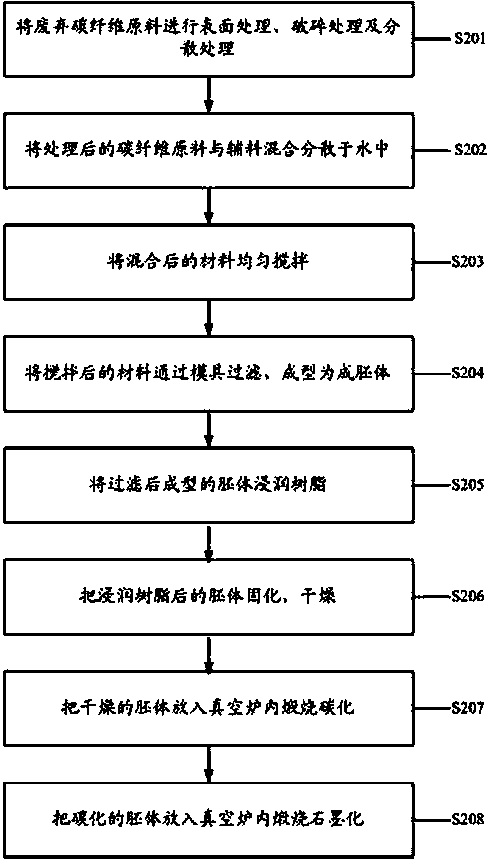

[0047] Please refer to image 3 , this embodiment is a flow chart of using waste carbon fiber as a raw material to manufacture a composite thermal insulation material. It can be seen that it mainly includes the following steps:

[0048] A manufacturing method of using waste carbon fiber to make a composite thermal insulation material, comprising:

[0049] S201: Surface treatment, crushing and dispersion of waste carbon fiber raw materials;

[0050] Carbon fiber is made by spinning, and the short carbon fiber is cut or crushed according to a preset length through a special tool (such as a gantry knife) or a gas crusher. Of course, in order to better combine with auxiliary materials, before preparing chopped carbon fibers, it is necessary to perform surface treatment on carbon fibers according to different auxiliary materials to improve the performance of composite materials.

[0051] If necessary, it is also necessary to put the treated chopped carbon fiber into the grinder f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com