Main chord and its standard section, tower crane

A technology of main chords and standard joints, which is applied to cranes and other directions, can solve problems affecting welding quality, high welding process requirements, uneven heat distribution, etc., to improve welding quality, reduce thickness difference, and reduce welding process requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments. It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict.

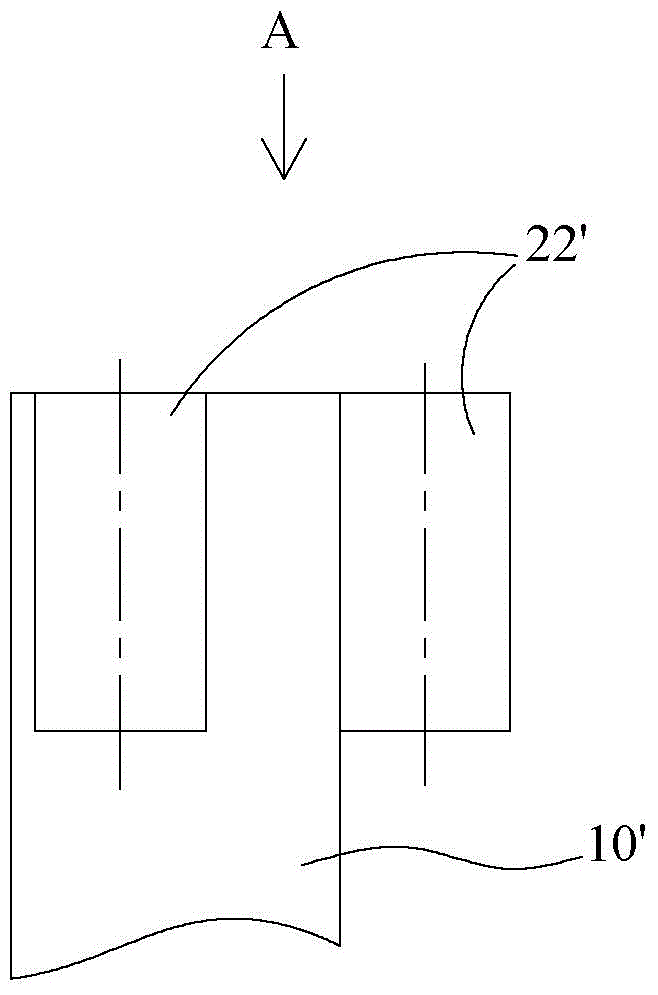

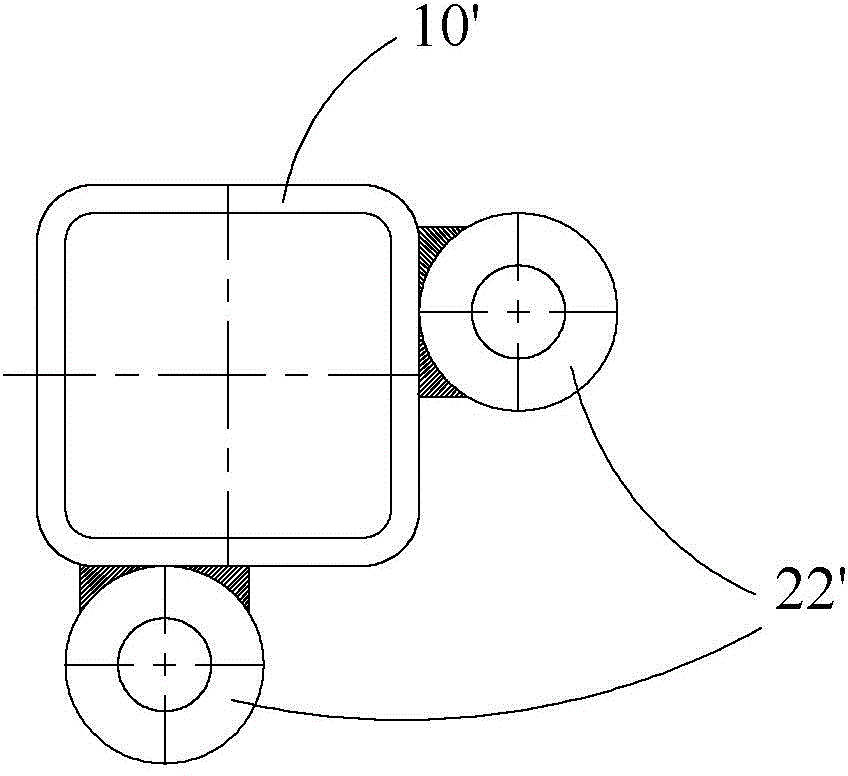

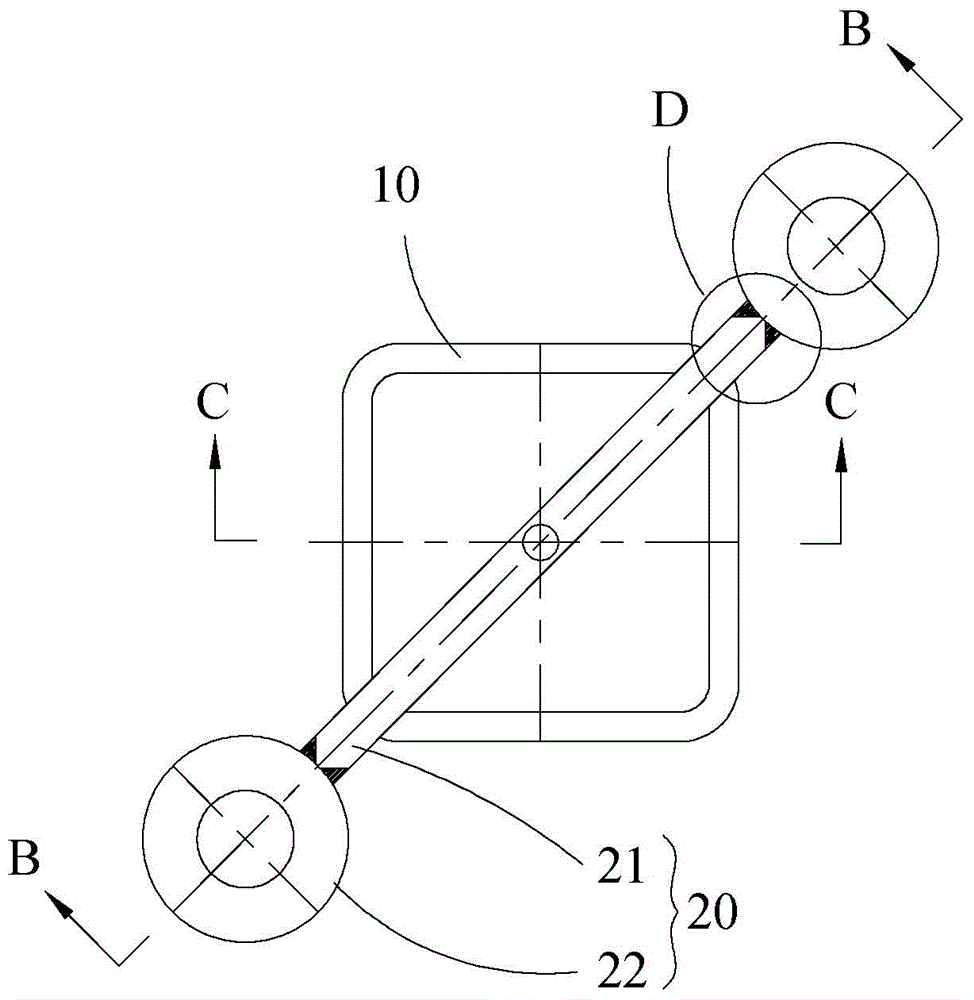

[0027] like Figure 3 to Figure 6 As shown, according to the embodiment of the present invention, a main chord is provided. Preferably, the main chord is applied to a standard section of a tower crane. The main chord includes a main chord body 10 and a connecting structure 20, wherein the connecting structure 20 includes a connecting plate 21 and a connecting sleeve 22, the connecting plate 21 is welded and fixed on the main chord body 10, and the connecting sleeve 22 is welded and fixed on the connecting plate 21 Above, the connecting sleeve 22 is used as the main connection basis for the connection of two adjacent main chord bodies 10, the thickness of the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com