Space microgravity environment ground simulation experiment device

A technology of ground simulation and experimental equipment, applied in the field of simulation, can solve the problems of high cost and short test time, and achieve the effect of low cost, convenient operation and unlimited test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

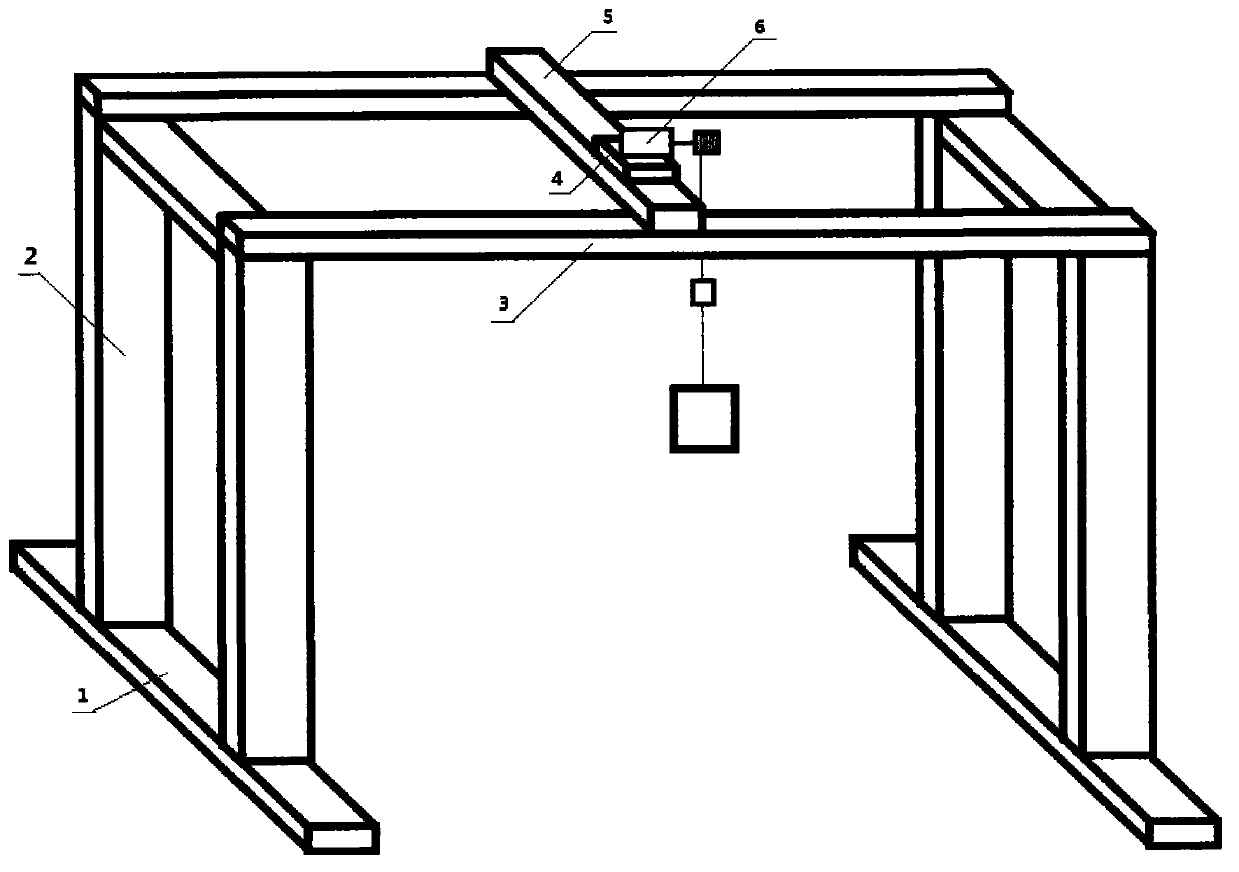

[0014] Such as figure 1 As shown, a space microgravity environment ground simulation experiment device includes a foundation 1, two supporting columns 2, a horizontal air-floating rail 3, a longitudinal air-floating rail 5, a pulley 4 and a weightlessness simulation control system 6, and two supporting columns 2 They are respectively installed horizontally on the foundation 4, the horizontal air-floating guide rail 3 is installed on the two supporting columns 2, the longitudinal air-floating guide rail 5 is installed on the horizontal air-floating guide rail 3, the trolley 4 is installed on the longitudinal air-floating guide rail 5, and the weightlessness simulation control System 6 is installed on the tackle 4, and controller is installed on the tackle 4; Described weightlessness simulation control system 6 comprises servomotor 7, coiling wheel 8, hanging wire 9, force sensor 10 and aircraft 11, and servomotor 7 connects coil Wire wheel 8, wire winding wheel 8 are connected ...

Embodiment 2

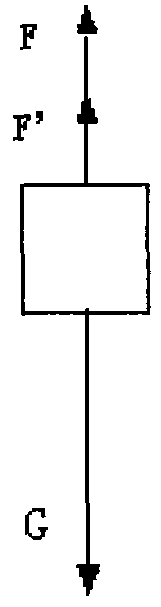

[0016] according to figure 1 , figure 2 , the working principle of the present invention is such: at first assume that aircraft is subjected to the effect of a force passing through the center of mass of the aircraft in three-dimensional space. Force can be equivalently decomposed into horizontal component and vertical component in three-dimensional space. The horizontal component of the force pulls the trolley to move in the horizontal direction, because there is approximately no friction between the air-floating guide rail and the trolley, so the approximately friction-free movement of the aircraft in the horizontal direction is realized by means of the air-floating guide rail; the vertical force of the force The component changes the feedback value of the force sensor that senses the pulling force of the hanging wire, thereby controlling the drive motor to make a corresponding response according to a predetermined control rule to ensure that the tension of the hanging wir...

Embodiment 3

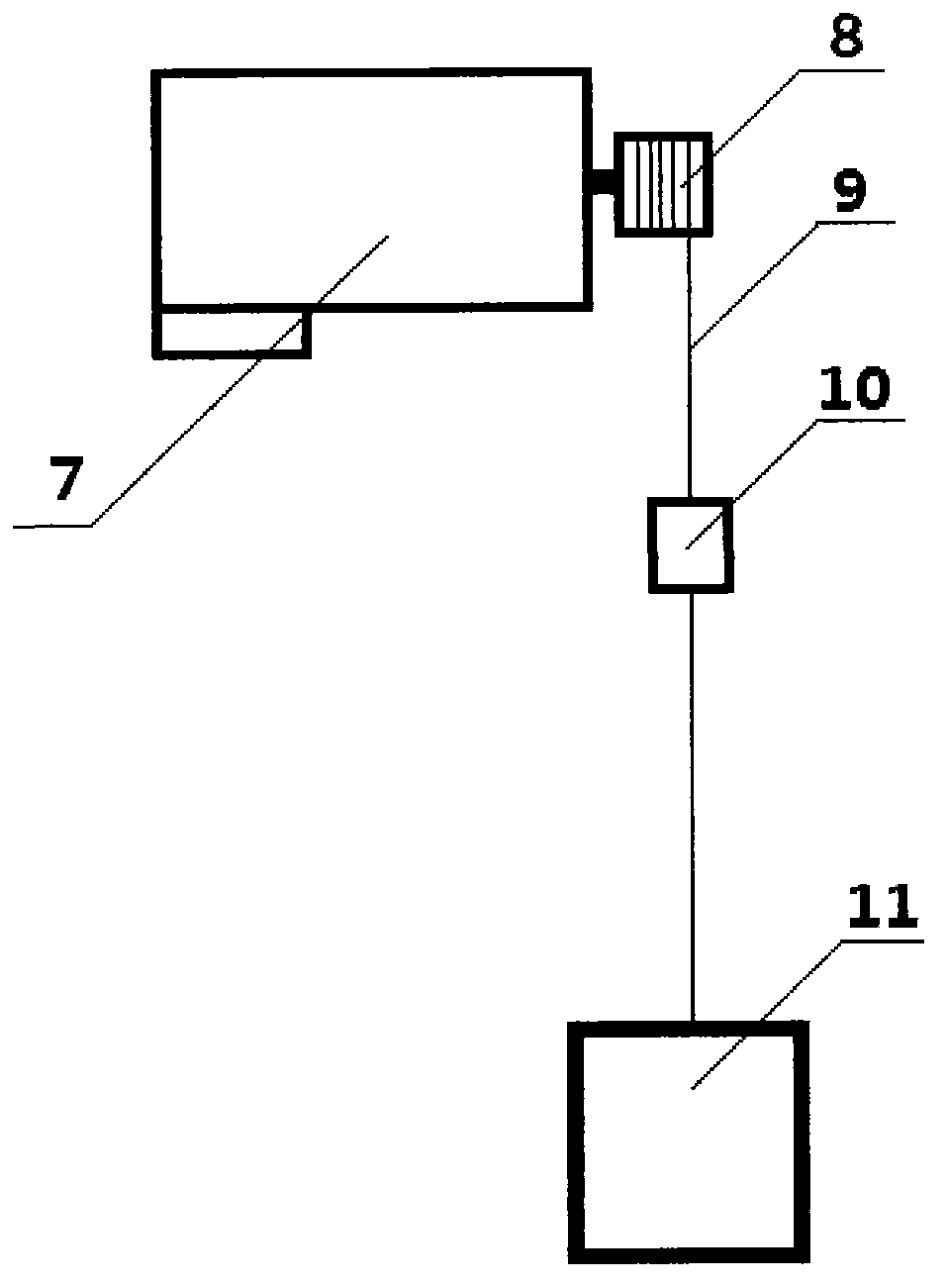

[0018] to combine figure 2 , image 3 , the structural design of the weightlessness simulation control system can be as follows figure 2 As shown, the weightlessness simulation control system 6 is composed of a motor 7 , a winding wheel 8 , a hanging wire 9 , and a force sensor 10 . The motor 7 is connected to the wire winding wheel 8 , the wire winding wheel 8 is connected to the hanging wire 9 , the hanging wire 9 is connected to the force sensor 10 , and the sensor 10 is connected to the aircraft 11 .

[0019] The working process of the weightlessness simulation control system is as follows: the control command of the servo motor comes from the controller placed on the pulley. When the tension of the hanging wire changes, the feedback value of the force sensor that senses the pulling force of the hanging wire changes, and the controller calculates the control command through the feedback value of the force sensor. The input signal of the controller is the feedback value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com