Railway wagon parking brake

A technology for parking brakes and railway wagons, applied to pneumatic brakes, railway car body parts, hydrostatic brakes, etc., can solve problems such as low work efficiency, difficult control, and high difficulty, and achieve convenient combination, reliable principle, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

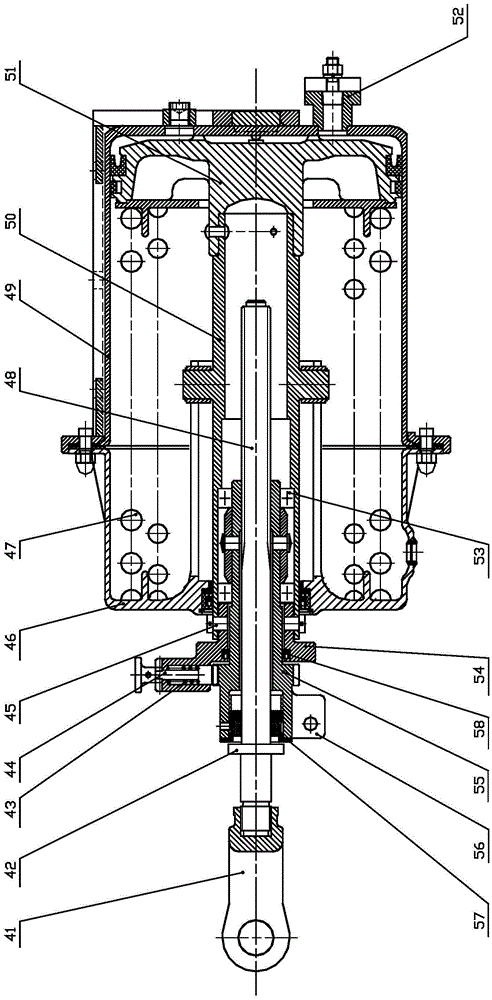

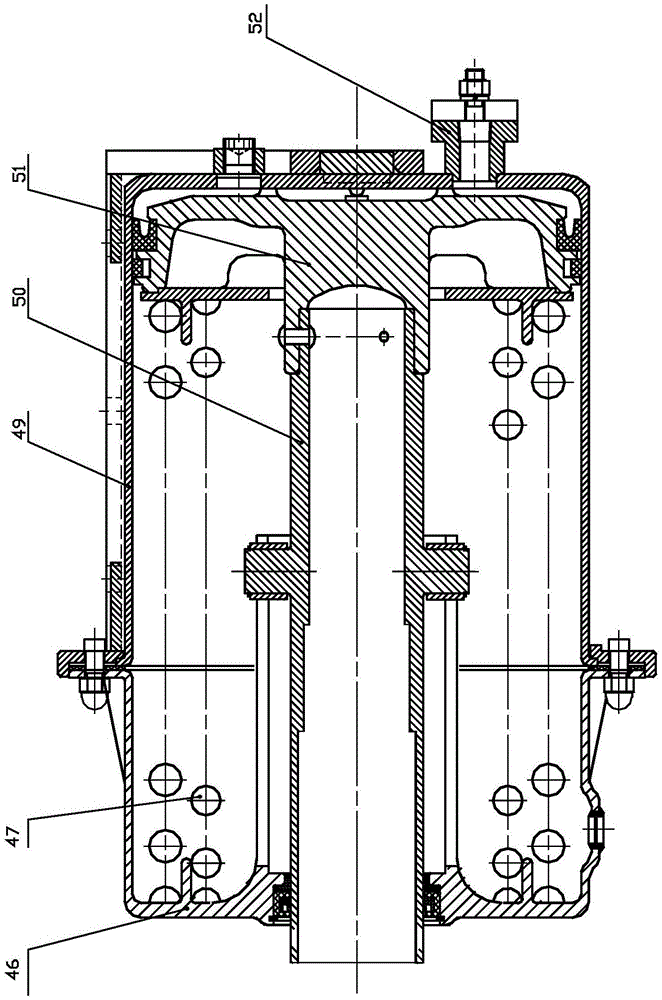

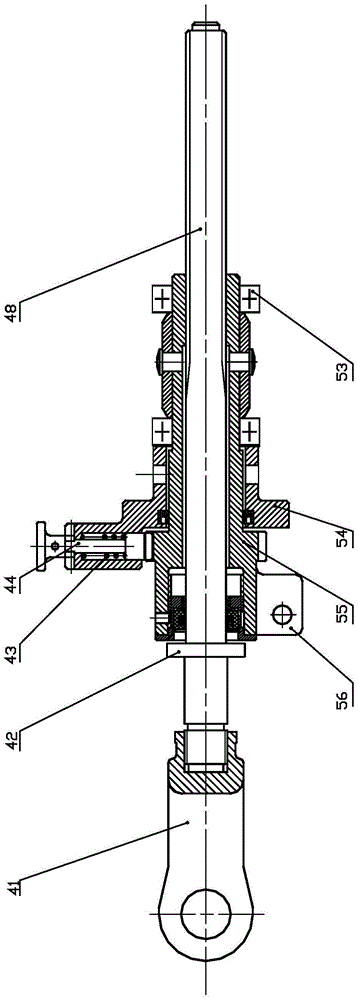

[0042] Such as Figure 1-7 As shown, the railway freight car parking brake of the present invention is mainly composed of an energy storage cylinder and a telescopic pull rod mechanism. The structure of each part is described as follows:

[0043] The energy storage cylinder consists of an energy storage cylinder body 49 and an energy storage cylinder head 46. The bottom of the energy storage cylinder body 49 is provided with a charging and exhaust flange joint 52. The energy storage cylinder body 49 is provided with a piston 51. The design stroke of the piston 51 is 160mm, an energy storage spring 47 is arranged between the backing plate at the bottom of the piston 51 and the energy storage cylinder cover 46, the center of the bottom of the piston 51 is connected with one end of the hollow piston rod 50, and the other end of the holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com