A combination fixture for rail vehicle machining

A technology of combining fixtures and rail vehicles, which is applied in the directions of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing the utilization rate of equipment, and the fixtures cannot be completely spread out, so as to improve the utilization rate and overcome flexibility. Insufficient sex, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

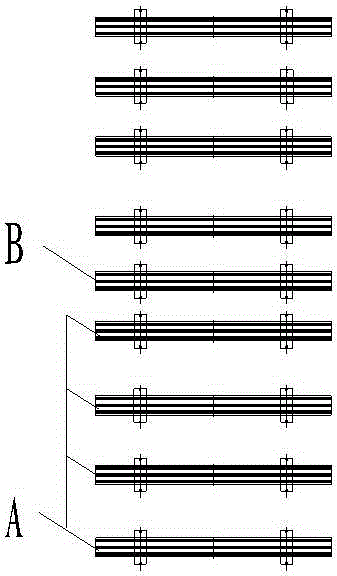

[0033] like figure 1 As shown, a combination fixture for rail vehicle machining is composed of 4 A unit modules and 16 B unit modules (not fully shown) arranged in parallel, and the A unit module is located on the outside of the B unit module.

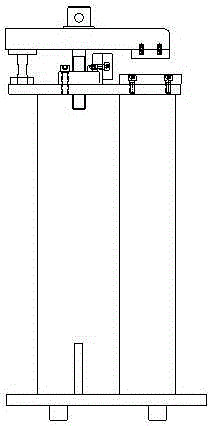

[0034] like figure 2 As shown, the A unit module includes the beam platform 8, the floor machining fixture, the overall machining fixture after the roof is welded, and the long and large section machining fixture. The overall machining jig is set on the left and right sides of the long and large bar machining jig, and the floor machining jig is set on the outside of the overall machining jig after the roof is welded;

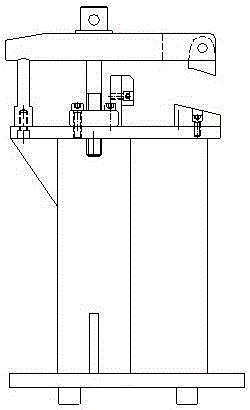

[0035] like image 3 As shown, the B unit module includes the beam platform 8, the overall machining fixture after the roof is welded and the long and large section machining fixture. The long and large section machining fixture is set in the middle of the beam platform 8, and the overall machining fixture after the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com