Independent automatic electrode cap replacement unit

An automatic replacement and electrode cap technology, which is applied in the direction of resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of automobile production capacity impact, single function, automatic electrode cap replacement equipment without corresponding products, etc., to achieve efficiency and reliability High, volume-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

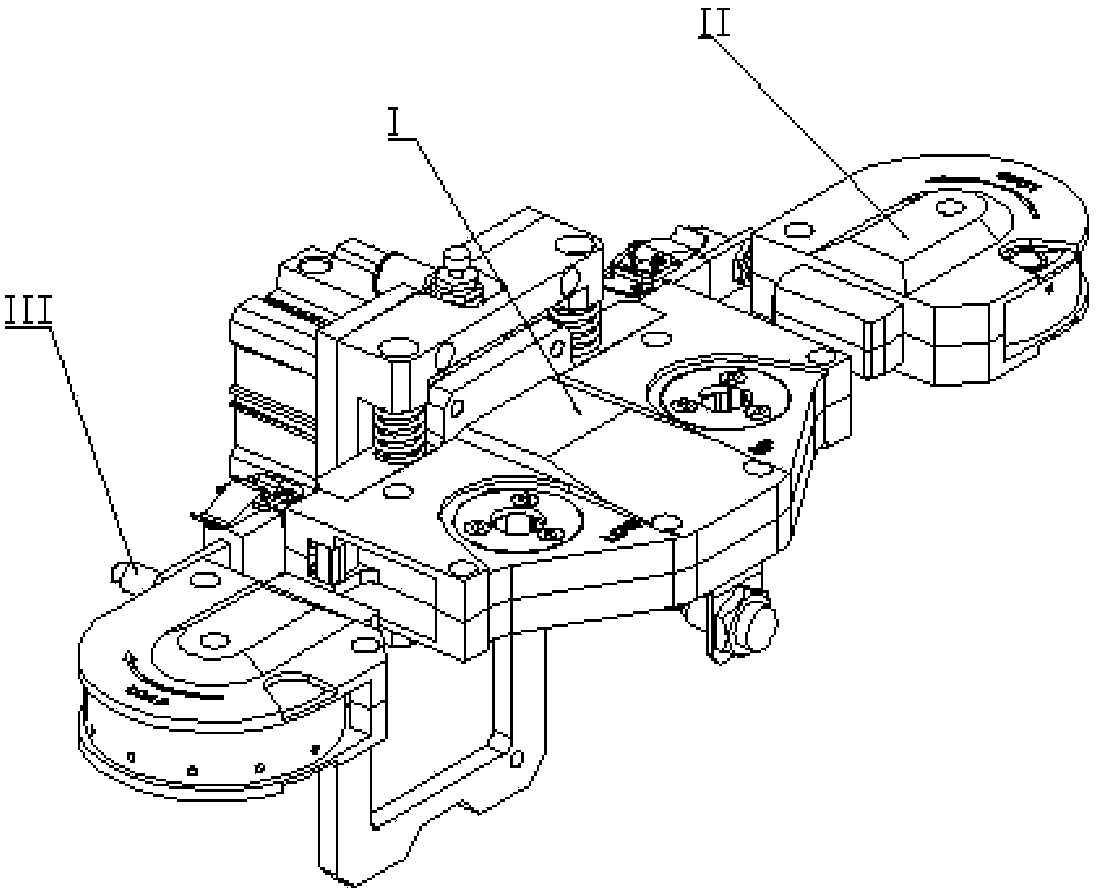

[0024] The present invention provides a kind of self-contained electrode cap automatic replacement equipment aiming at existing deficiencies, such as figure 1 As shown, it includes an electrode cap removal unit I, an electrode cap storage unit II and a sensing detection unit III. The electrode cap storage unit II is arranged on both sides of the electrode cap removal unit I, and is connected in the form of quick insertion. The sensing detection unit III includes five sensors, which are respectively installed in five positions of the electrode cap removal unit I, for 1 electrode cap disassembly detection sensor 13, 2 electrode cap quantity detection sensors 9, and 2 stroke detection sensors 18.

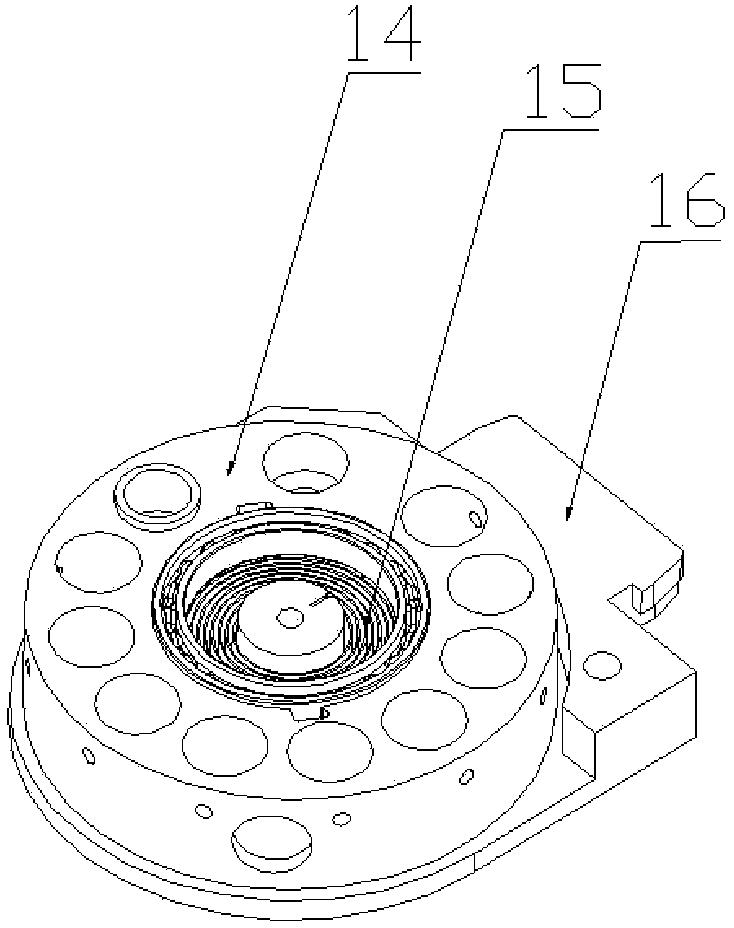

[0025] Such as figure 2 As shown, the electrode cap remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com