A self-flattening shirt collar and its sewing method

A collar and shirt technology, applied in the field of shirt collars, can solve the problems of unevenness, easy wrinkles on the collar, affecting the aesthetic comfort of shirts, etc., and achieves the effects of suitable neck hugging, smooth appearance, and reasonable relationship between inner and outer layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The total length of the neckline of a men's shirt is 37cm, and the collar structure is as follows:

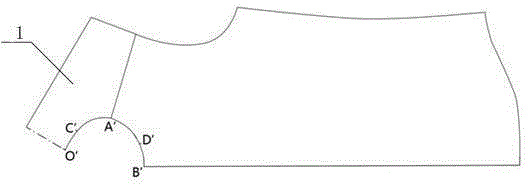

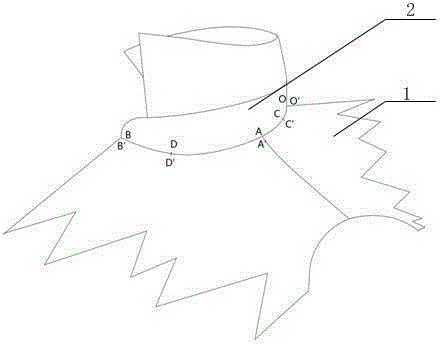

[0039] as attached figure 1 As shown, the collar opening 1 includes the rear center O' of the collar opening, the shoulder point A' of the collar opening, the end point B' of the front neck opening, the rear control point C' of the collar opening and the front control point D' of the collar opening. The distance to the back control point C' of the collar is 4.0cm; the distance from the front collar end point B' to the front control point D' of the collar is 4.0cm; the distance from the back center of the neckline O' to the collar shoulder point A' is 10.1 cm, the distance from collar shoulder point A' to front neckline end point B' is 8.0 cm.

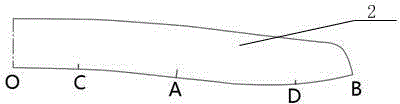

[0040] as attached figure 2 As shown, the collar seat 2 includes the rear center O of the collar seat, the shoulder point A of the collar seat, the front center point B, the rear control point C of the collar seat, and the fron...

Embodiment 2

[0043] The total length of the neckline of a men's shirt is 45cm, and the collar structure is as follows:

[0044] as attached figure 1 As shown, the collar opening 1 includes the rear center O' of the collar opening, the shoulder point A' of the collar opening, the end point B' of the front neck opening, the rear control point C' of the collar opening and the front control point D' of the collar opening. The distance to the back control point C' of the collar is 5.0cm; the distance from the front collar end point B' to the front control point D' of the collar is 5.0cm; the distance from the back center of the collar O' to the collar shoulder point A' is 11.7cm, the distance from collar shoulder point A' to front neckline endpoint B' is 10.4 cm.

[0045] as attached figure 2 As shown, the collar seat 2 includes the rear center O of the collar seat, the shoulder point A of the collar seat, the front center point B, the rear control point C' of the collar seat, and the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com