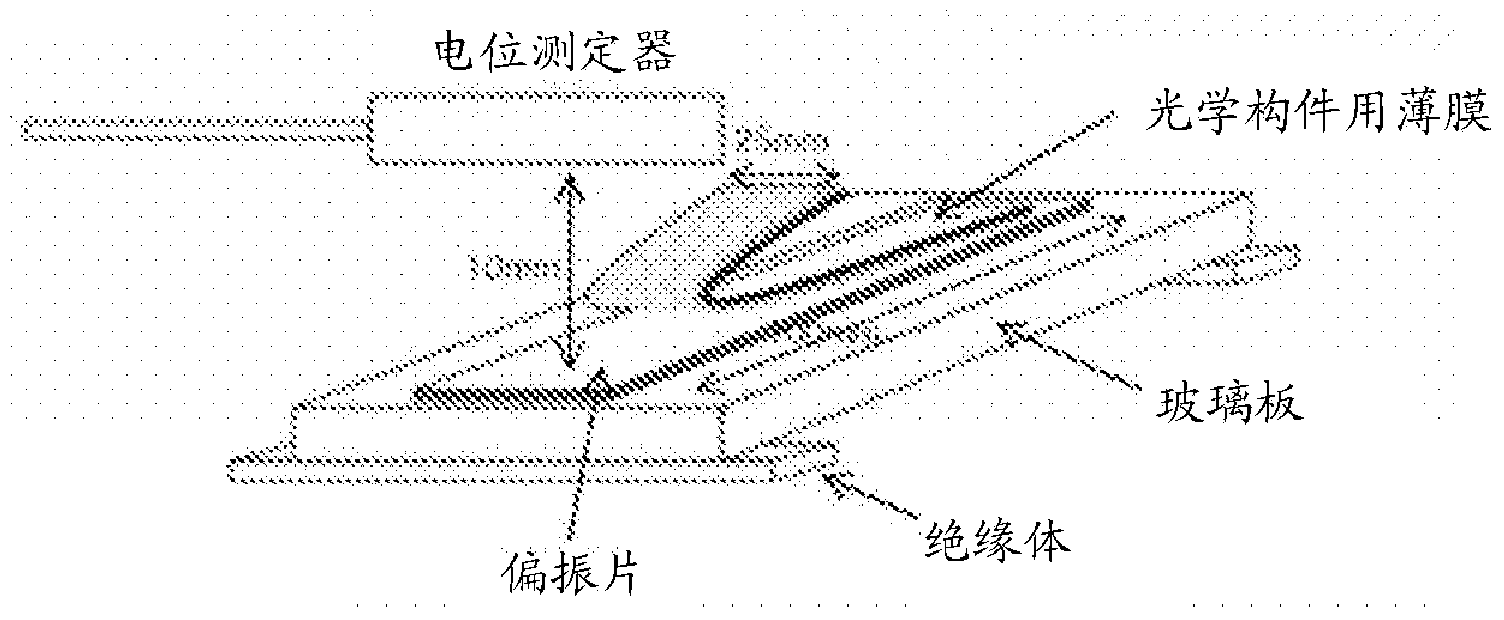

Adhesive composition and film for optical member

A composition and adhesive technology, applied in the direction of optical components, adhesive types, ester copolymer adhesives, etc. Excellent glue transfer viscosity, suppressing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0128] The effects of the present invention will be specifically described below with examples and comparative examples, but the present invention is not limited by these examples. Moreover, unless otherwise indicated, "part" and "%" are mass standards.

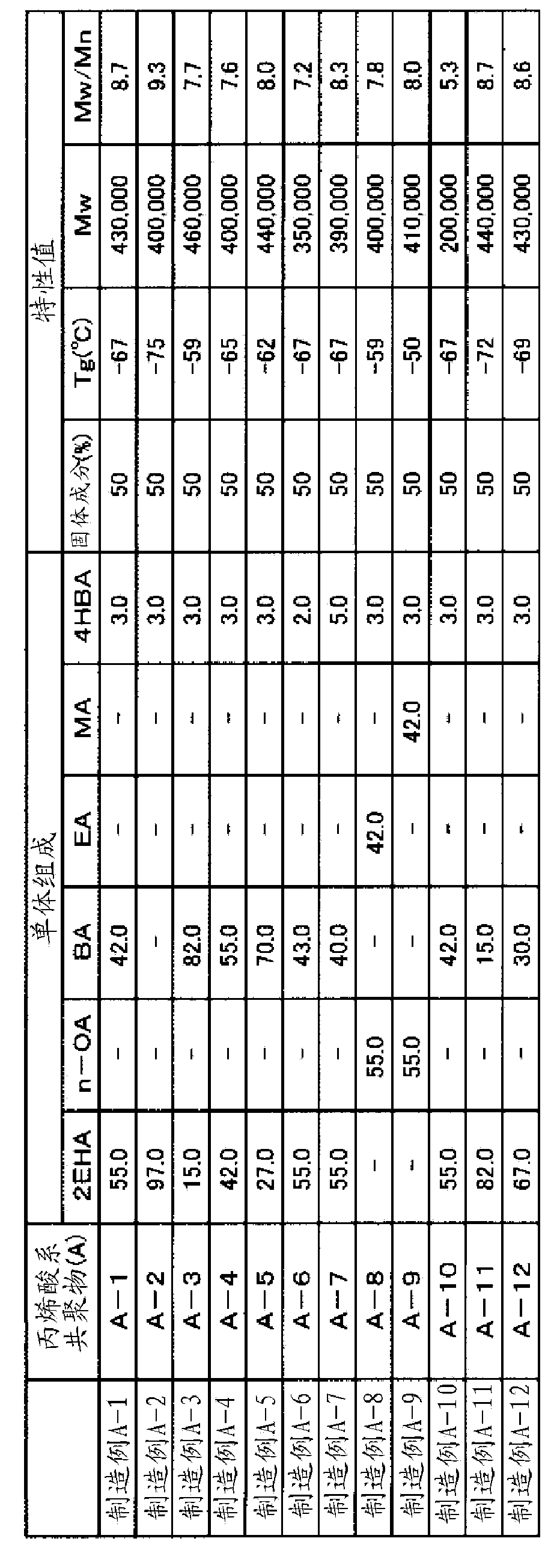

[0129] Production of acrylic copolymer (A) solution

manufacture example A-1)

[0131] 35.0 parts by mass of ethyl acetate were added to a reaction container equipped with a thermometer, a stirrer, a nitrogen gas introduction pipe, and a reflux cooler. In another container, 55.0 parts by mass of 2-ethylhexyl acrylate (2EHA), 42.0 parts by mass of n-butyl acrylate (BA), and 3.0 parts by mass of 4-hydroxybutyl acrylate (4HBA) were added and mixed to prepare monomer The mixture, 15% by mass of which was charged into a reaction vessel, was then heated to reflux temperature while stirring under a nitrogen atmosphere. Thereafter, a mixed solution obtained by mixing the entire amount of the remaining monomer mixture, 10 parts by mass of ethyl acetate, 10 parts by mass of toluene, and 0.1 parts by mass of azobisisobutyronitrile was gradually added to the reaction at the reflux temperature over 100 minutes. container, then reacted for 45 minutes while maintaining reflux temperature. Thereafter, a solution obtained by mixing 15 parts by mass of ethyl acetate and 0...

manufacture example A-2~A

[0133] (Manufacturing examples A-2 to A-12)

[0134] Solutions of acrylic copolymers (A-2) to (A-12) were produced in the same manner as in Production Example A-1, except that the monomer composition was changed to the monomer composition shown in Table 1, and the initiator amount was appropriately adjusted. . Table 1 shows the solid content, glass transition temperature (Tg), weight average molecular weight (Mw), and degree of dispersion (Mw / Mn) of the obtained acrylic copolymer solution.

[0135] [Table 1]

[0136]

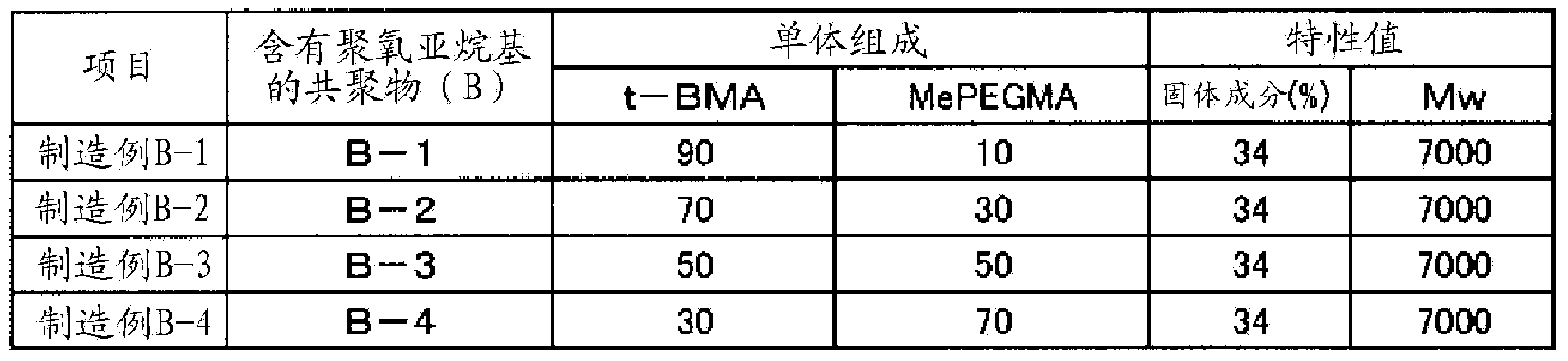

[0137] Production of polyoxyalkylene-containing copolymer (B)

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com