Automobile optical fiber illumination engine

An optical fiber lighting and automotive technology, applied in the field of automotive lighting systems, can solve the problems of the light source being affected by the lamp body, energy consumption, hidden danger of spontaneous combustion of cables, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

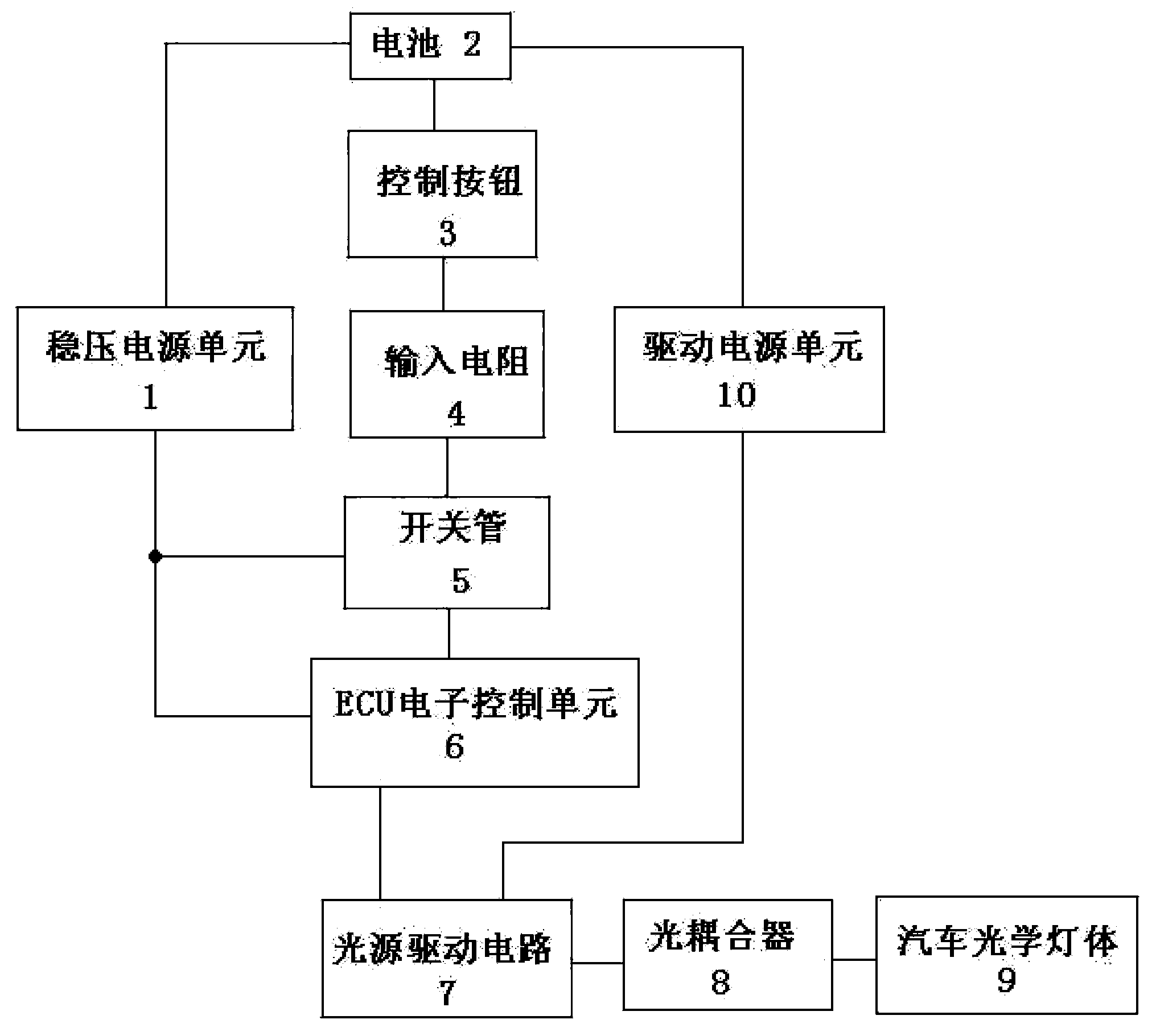

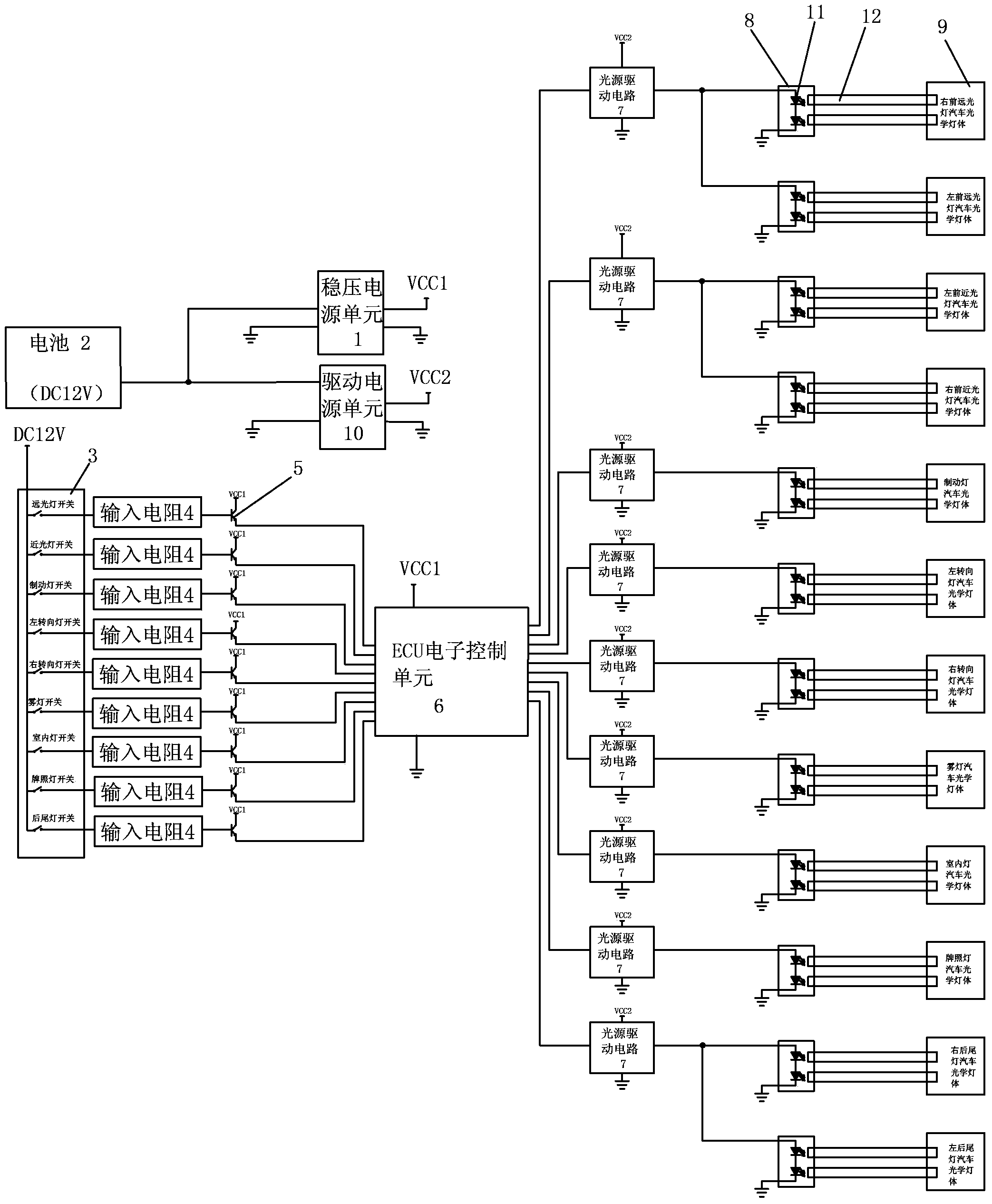

[0032] Embodiment one: a kind of automobile optical fiber lighting engine, such as figure 1 , figure 2 As shown, it includes a battery 2, a regulated power supply unit 1, a drive power supply unit 10, several mutually independent control buttons 3, several mutually independent input resistors 4, several mutually independent switch tubes 5, a ECU Electronic control unit 6, several mutually independent light source driving circuits 7, several mutually independent optical couplers 8, several optical fibers 12 and several mutually independent automotive optical lamp bodies 9, wherein, ECU The electronic control unit includes several signal input interfaces and several signal output interfaces; the battery is connected to the electrical input terminal of the regulated power supply unit, the battery is connected to the electrical input terminal of the driving power supply unit, and the front end of the control button is connected to the battery; the input resistance The number is...

Embodiment 2

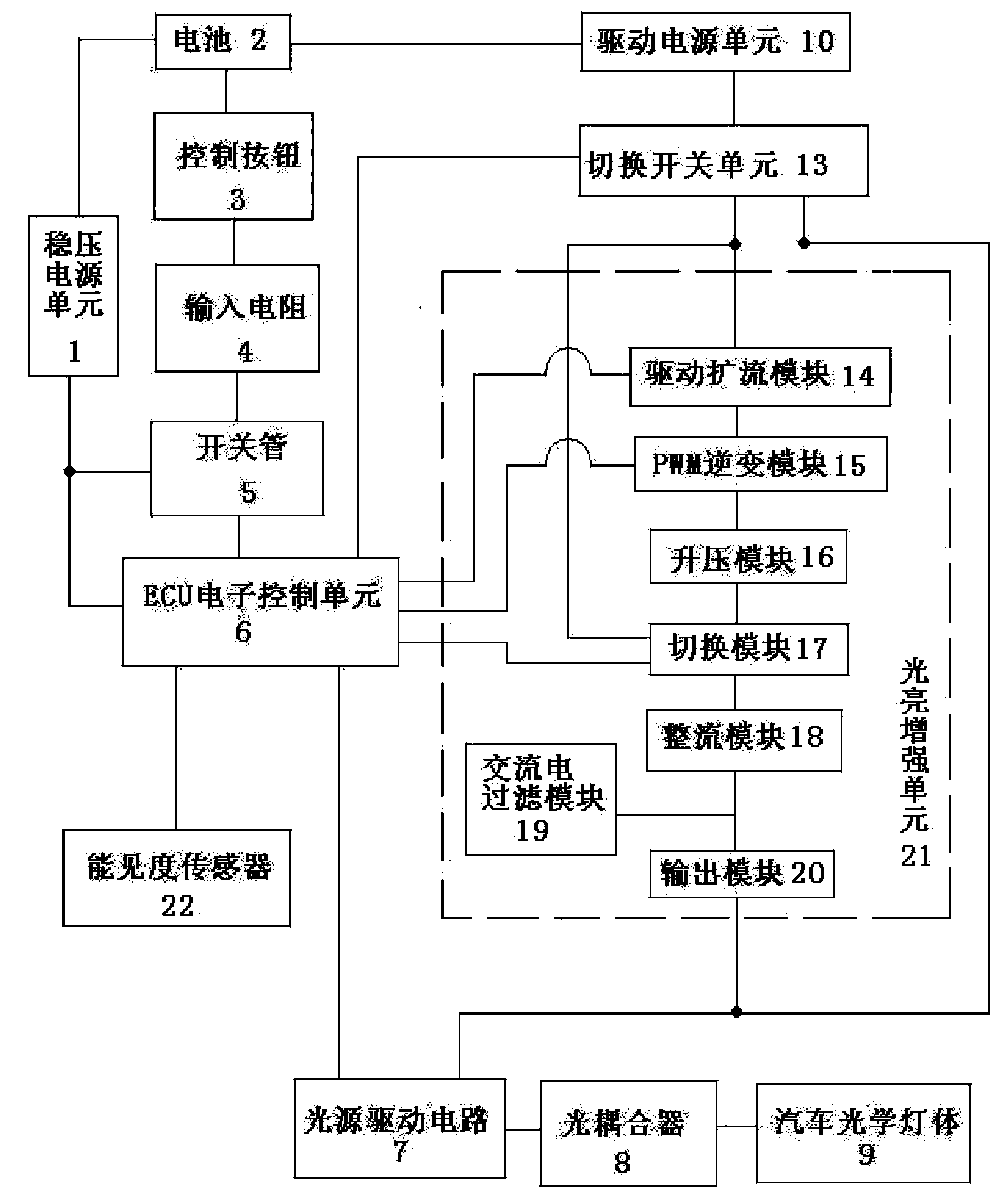

[0034] Embodiment two, see image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the second embodiment adds the visibility sensor 22, the switching unit 13 and the light enhancement unit 21 on the basis of the first embodiment. Specifically, the visibility sensor 22 is used to measure the visibility of the air. The function of the switch unit 13 is to switch and select the DC input mode of the light source drive circuit under the instruction of the ECU electronic control unit, specifically to switch and select the DC output after the drive power unit, and to switch the selected DC or directly Sending to the electrical input of the light source driving circuit, or directly feeding to the electrical input of the drive expansion module of the brightness enhancement unit, there are only two options, and only one of the two options can be selected at the same time. The function of the light enhancement unit 21 is to provide the light source driving ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com