Device and method for preparing gate electrodes of solar cell

A technology for solar cells and grid electrodes, applied in the field of solar cells, can solve the problems of low light absorption rate and low conversion efficiency of solar cells, and achieve the effect of high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

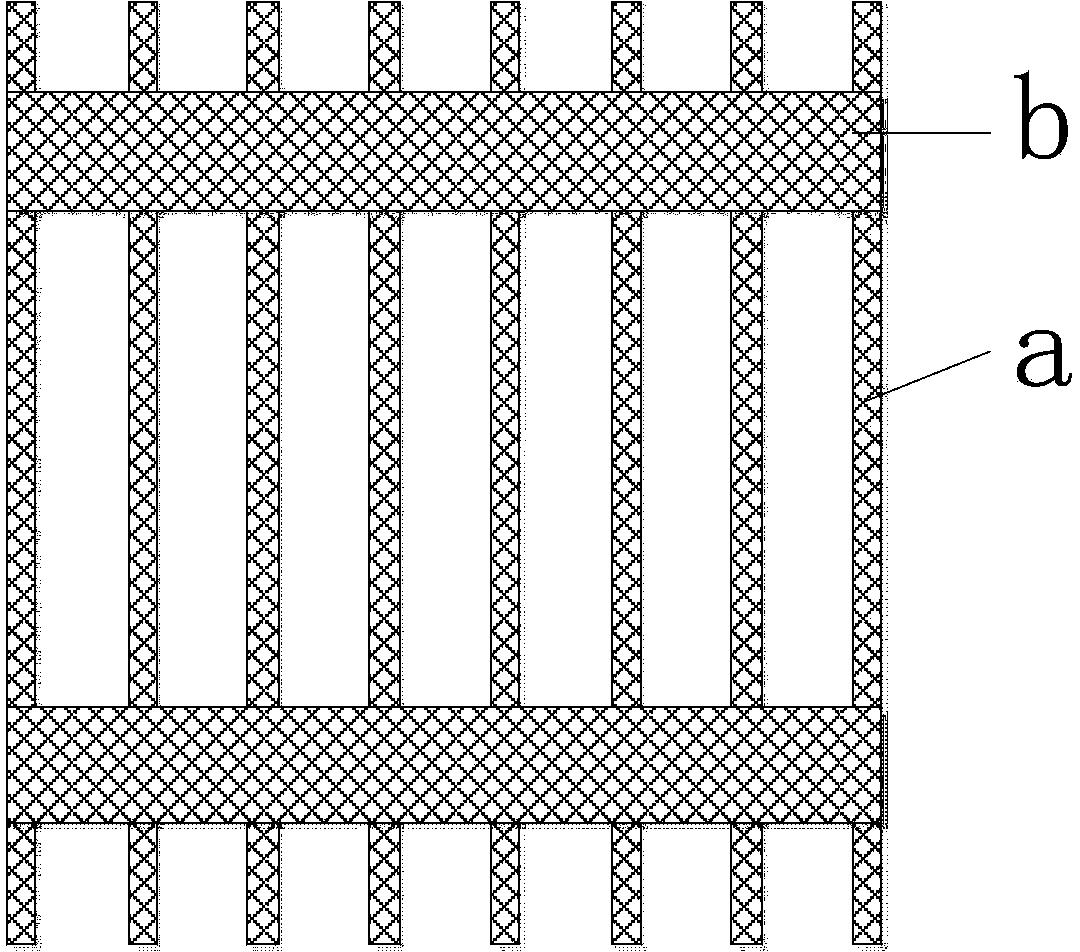

[0039] figure 2 It is a schematic structural diagram of a device for preparing solar cell grid electrodes provided by an embodiment of the present invention, including: a silver paste supply device 1, a nozzle height adjustment module 2, a nozzle 3, a programmable high-voltage generator 4, an adsorption platform 5, and a motion platform 6 , solar substrate 7, control unit 8. The silver paste supply device 1 supplies silver paste to the nozzle 3 and provides the back pressure required for electrospinning. The nozzle height adjustment module 2 is used to precisely adjust the height of the nozzle 3 . The height of the nozzle 3 is defined as the distance between the printing end and the solar cell to be printed. Nozzle 3 is a direct actuator for printing grid electrodes, including a printing end, a silver paste supply interface and an electrical interface. The nozzle 3 is to be metallized for establishing an electric field. The function of the nozzle 3 is: as the positive ele...

Embodiment 1

[0071] Example 1: Now it is necessary to print an n with a side length of 125mm and a diagonal of 165mm + The upper electrode of the p-type monocrystalline silicon solar cell is made of silver paste, and its volume resistivity is 3.0uΩ.cm. According to the solar cell grid optimization theory and technological constraints, it is calculated that the spacing of the fine grid lines should be controlled at About 2.5mm, the height is controlled between 10-30um. Further, array nozzles are used to improve production efficiency.

[0072] Specific steps are as follows:

[0073] (1) The nozzle array is arranged in two rows, placed at equal intervals, each row has 25 nozzles, and the distance between the nozzles is set to 5mm, and the diameter of the nozzles is 200um, so that the theoretical thin grid line spacing printed out is 2.5mm, and the nozzles The width that can be printed is equal to the width of the battery sheet, and the printing of the fine grid can be completed in a single ...

Embodiment 2

[0079] Embodiment 2: On the basis of Embodiment 1, the height of the thin grid is controlled between 15-20um, and the parameters are reset as follows:

[0080] (1) The nozzle array is arranged in two rows, placed at equal intervals, each row has 25 nozzles, and the distance between the nozzles is set to 5mm, and the diameter of the nozzles is 300um, so that the theoretical thin grid line spacing printed out is 2.5mm, and the nozzles The width that can be printed is equal to the width of the battery sheet, and the printing of the fine grid can be completed in a single printing.

[0081] (2) Place the solar cells to be printed with grid lines on the adsorption platform and absorb them well.

[0082] (3) Add the silver paste to be printed into the cavity of the nozzle, and fill the metal nozzle. Connect the nozzle to the positive pole of the high voltage generator, and set the voltage to 1.5kV;

[0083] (4) Adjust the height of the nozzle array, and set the height to 1.5cm;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com