Double-plastics finned wound corrugated pipe and method for manufacturing same

A corrugated pipe and reinforcement technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of easy corrosion and reduced ring stiffness, and achieve the effect of reliable connection, full shape, and guaranteed ring stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

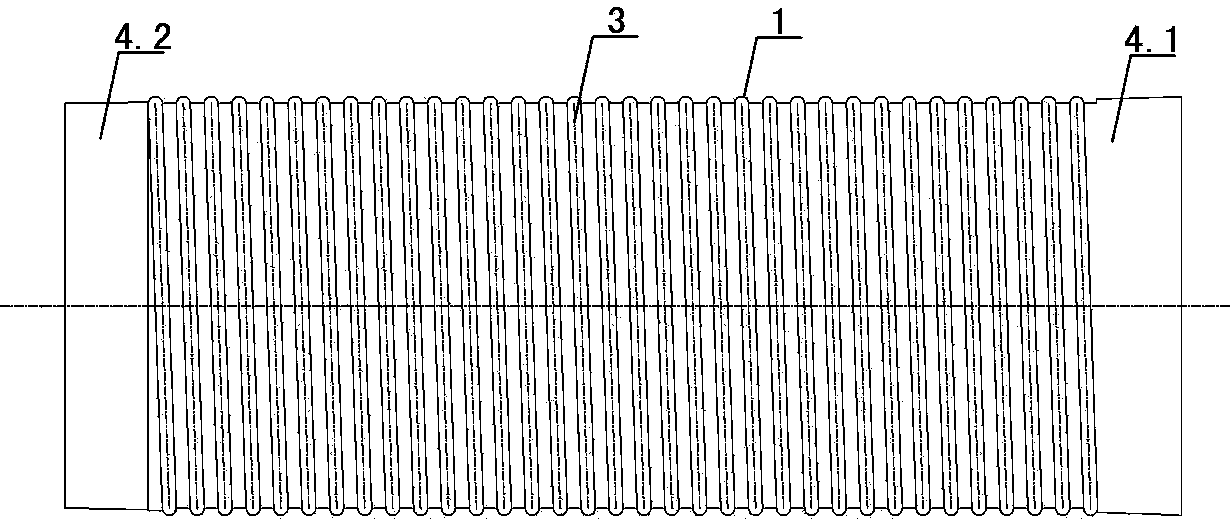

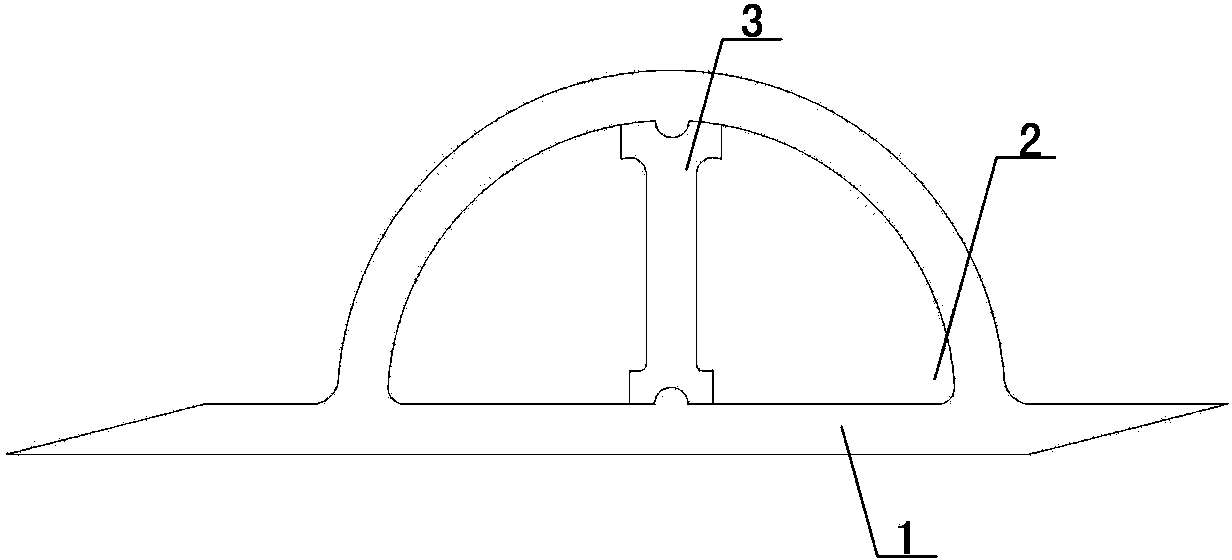

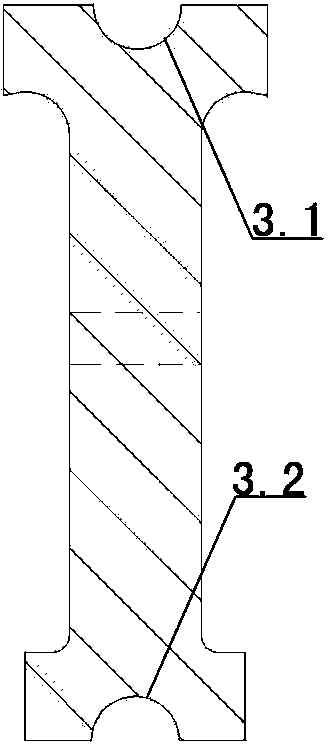

[0074] Examples see figure 1 As shown, this kind of double-plastic reinforced winding bellows has a pipe wall 1 that is extruded, inflated, spirally wound and hot-melted into one bellows shape, and there are sockets 4 at both ends, and the head of the double-plastic reinforced winding bellows The end is a contracted socket end 4.2, and the tail end is a diffused socket end 4.1. There is a cavity 2 in the corrugation of the pipe wall 1, and there is a sheet-shaped plastic reinforcing rib 3 in the cavity 2. The plastic The reinforcing rib 3 is perpendicular to the pipe wall 1, its outer edge is hot-melt connected with the crest annular surface of the cavity, and its inner edge is connected with the other surface of the cavity in a circumferential hot-melt direction. The material of the pipe wall 1 is PE polyethylene. The material of the plastic rib 3 is PP polypropylene.

[0075] see figure 2 As shown, the two leaf edges of each circle of tube wall are parallel inclined plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com