A kind of manufacturing method of double-flat-wall steel-plastic composite pipe

A steel-plastic composite pipe and a technology for manufacturing method, which are applied to tubular articles, other household appliances, household appliances, etc., can solve problems such as affecting the service life of engineering quality pipes, inability to use pressure-conveying liquid pipelines, and uneven thickness of plastic layers, etc. , to improve the efficiency of on-site operations, save plastic raw materials, and achieve good molding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

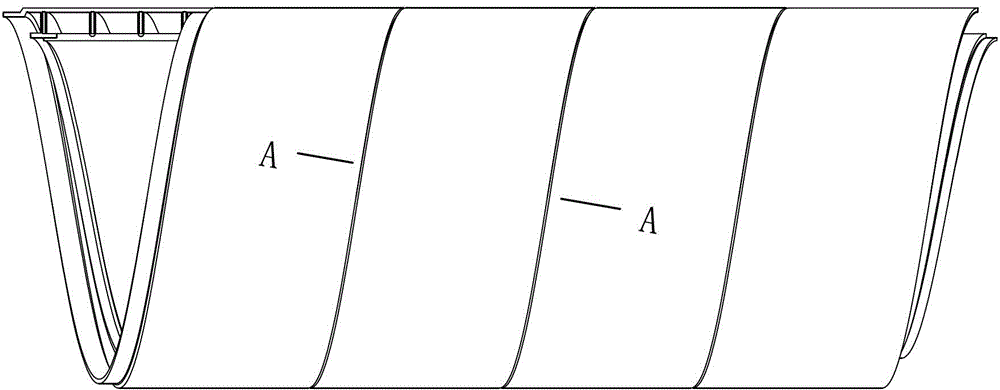

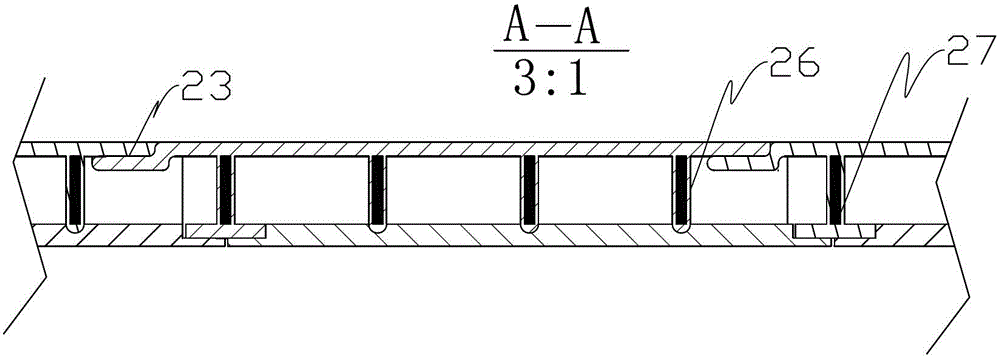

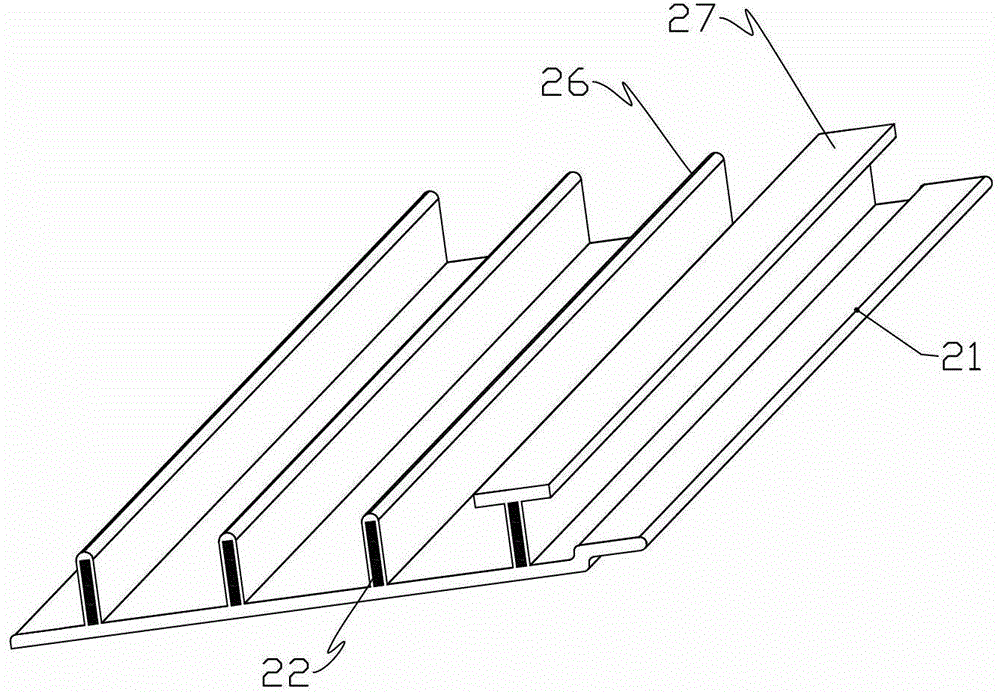

[0039] Such as figure 2 , image 3 As shown, a steel-plastic strip is an extruded steel-plastic strip 21, and a vertical steel rib 22 is embedded in the inner rib of the steel-plastic strip, and the vertical steel rib is essentially a steel strip; In this way, both the anti-corrosion performance of the plastic and the rigidity of the vertical steel rib are used to ensure the ring rigidity of the buried pipe. There are two types of reinforcing ribs, one is I-shaped reinforcing rib 26, and the other is T-shaped reinforcing rib 27, wherein the T-shaped rib is used for matching and welding with the outer plastic strip. At the same time, the lap joint structure 23 is adopted at the side joint of the steel-plastic strip 21, and the lap joint is carried out by hot-melt welding, so that when the adjacent strip bodies are combined, the contact when the two sides are bonded is greatly increased. The area makes the pipes more firmly bonded and greatly improves the joint strength of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com