Pure oxygen and diesel combined heat carrier generator system

A technology of composite heat carrier and generator, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of composite heat carrier oil increase technology limitation, easy gas channeling, etc., to prevent high nitrogen content, Achieve zero carbon emissions and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

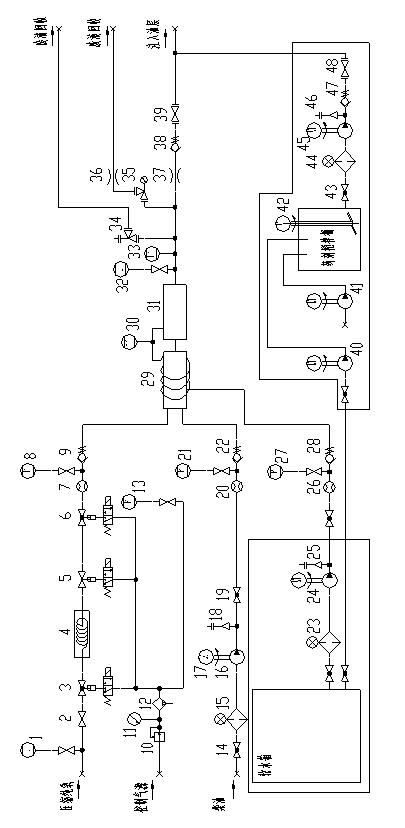

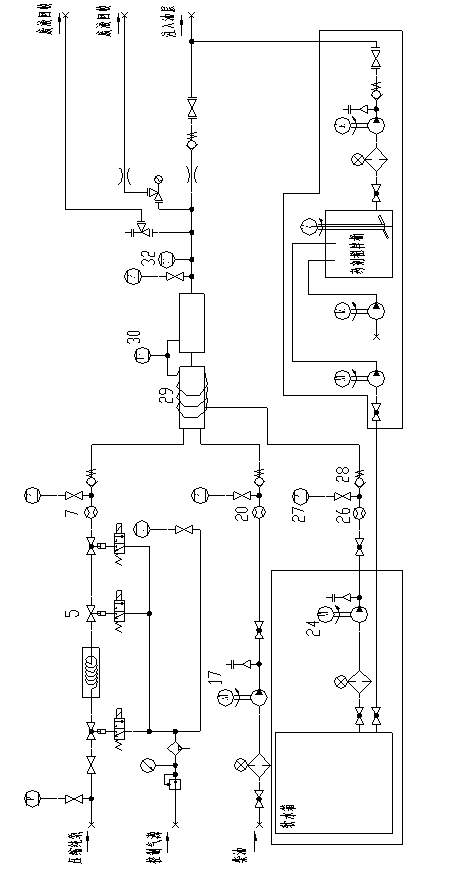

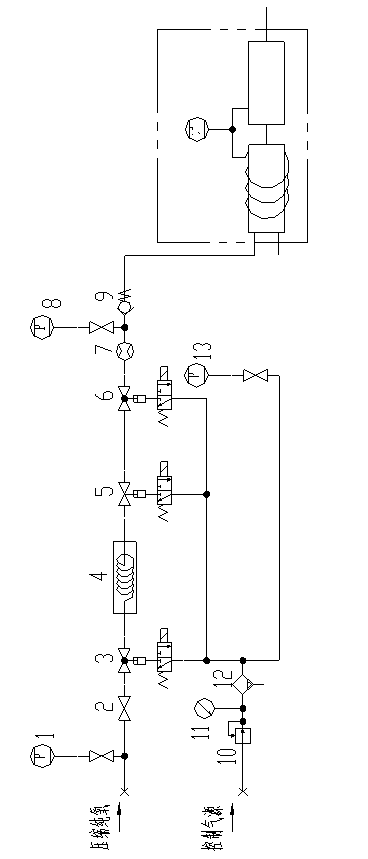

[0068] see figure 1 , a pure oxygen diesel composite heat carrier generator system of the present invention, it comprises the pure oxygen composite heat carrier generator that is made up of pure oxygen combustor 29 and heat carrier gasification chamber 31, described pure oxygen composite heat carrier generator input The ends are respectively connected with the pure oxygen pipeline, the diesel pipeline and the water pipeline, and the pure oxygen pipeline is provided with a pure oxygen pressure sensor 1, a pure oxygen stop valve 2, a No. 1 pure oxygen dynamic ball valve 3 and a pure oxygen temperature control System 4, No. Ⅱ pure oxygen flow regulating valve 5, No. Ⅲ pure oxygen dynamic ball valve 6, pure oxygen mass flow meter 7, generator inlet pressure transmitter 8 and one-way check valve 9, the pure oxygen pipeline is connected in parallel There is a regulating pipeline, and the regulating pipeline is provided with a control air source pressure regulating valve 10, a contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com