Multistage Single Screw Continuous Steam Explosion Device for Plant Fiber

A plant fiber and single-screw technology, applied in the direction of raw material separation, etc., can solve the problems of difficult control of process parameters, poor reaction effect, low degree of automation, etc., to overcome the contradiction between pressure and temperature, safe and reliable equipment utilization, Good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

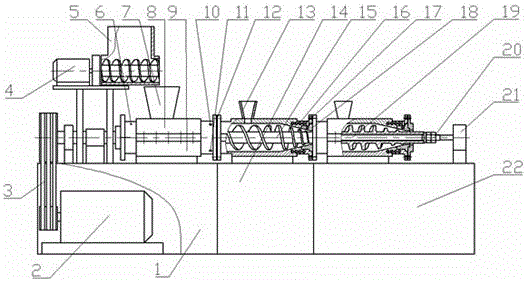

[0037] Such as figure 1 as shown, figure 1It is a structural schematic diagram of a multi-stage single-screw continuous steam explosion device for plant fibers of the present invention. The multi-stage single-screw continuous steam explosion device of plant fibers comprises: the first frame 1, the second frame 14, the third frame 22, the first frame 1 and the second frame 14 pass through the guide device and The fastening mechanism is fixed, the second frame 14 and the third frame 22 are fixed by the guide device and the fastening mechanism, which is convenient for disassembly and assembly, and can be refitted into a single-stage, two-stage, three-stage steam explosion machine as required 2 Installed on the first frame 1, the power is transmitted through the belt 3, the second motor 4 and the screw feeder 5 are fixed on the first frame 1 through the bracket, and there is a water filling hole 6 on the barrel to adjust the material Moisture content, the screw feeder 5 feeds th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com