Bottom blowing gas supply method for stainless steel converter and stainless steel converter bottom thereof

A technology of converter bottom blowing and stainless steel, applied in the manufacture of converters, etc., can solve problems such as brick collapse, furnace bottom scour, and furnace bottom refractory materials are prone to defects caused by machine vibration, so as to achieve the effect of synchronous life and reduced erosion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The present embodiment is carried out on the stainless steel converter 90t, and the gas is supplied at the bottom of the stainless steel converter of the present invention, and what is smelted is 430 stainless steel. In this process, the carbon content needs to be blown from 4.0% to 0.25%. Bottom gun gas distribution mode: carbon content reduced from 4.0% to 0.5% bottom gun center pipe and ring pipe for N 2 ; During the process of dropping from 0.5% to 0.25%, N is supplied in the central tube of the bottom gun 2 and O 2 , ring pipe for N 2 , N 2 :O 2 =2:1.

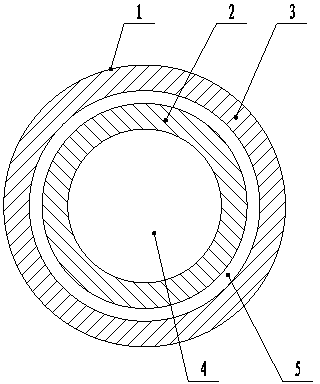

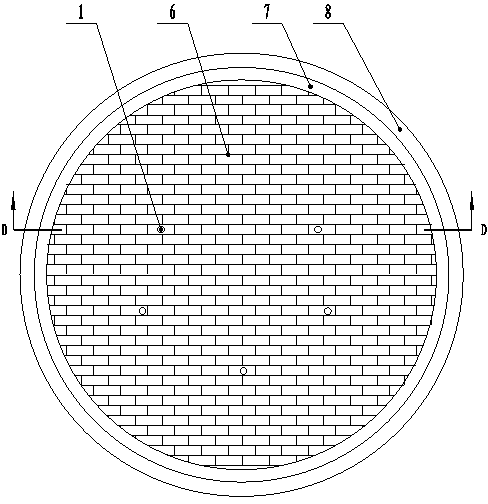

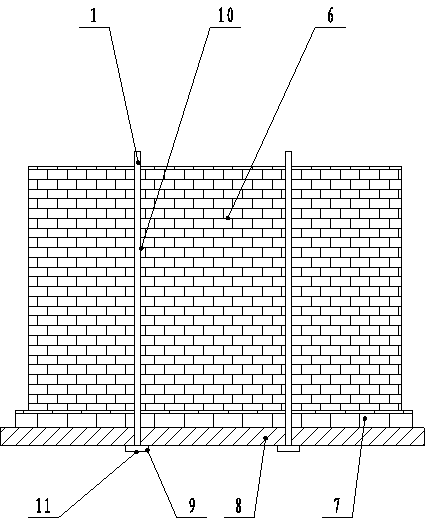

[0019] The diameter of the air supply hole 4 of the central pipe 2 is Φ12mm, the thickness of the central pipe 2 is 2mm, and the gap 5 between the ring pipe 3 and the central pipe 2 is 1mm. The ratio of the gas supply area of the ring pipe 3 ie the cross-sectional area of the gap 5 to the gas supply area of the central tube 2 ie the gas supply hole 1 is 0.47. See figure 1 .

[0020] On the premise of ...

Embodiment 2

[0022] The present embodiment is carried out on the stainless steel converter 90t, the gas is supplied at the bottom of the stainless steel converter of the present invention, and 409L stainless steel is smelted. In this process, the carbon content needs to be blown from 4.0% to 0.25%. Bottom gun gas distribution mode: the carbon content is reduced from 4.0% to 0.5% and Ar is supplied to the center tube and ring tube of the bottom gun; Ar and O are supplied to the center tube of the bottom gun during the process of decreasing from 0.5% to 0.25% 2 , ring pipe for Ar, N 2 :O 2 =2:1.

[0023] The diameter of the air supply hole 4 of the central pipe 2 is Φ12mm, the thickness of the central pipe 2 is 2mm, and the gap 5 between the ring pipe 3 and the central pipe 2 is 1mm. The gas supply area of the ring pipe 3, that is, the cross-sectional area of the gap 5, and the ratio of the gas supply area of the central tube 2, that is, the gas supply hole 1, is 0.47, see figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com