Bioenzyme-containing gasoline composite additive as well as preparation method and application for same

A compound additive and bio-enzyme technology, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of fuel improvement performance differences, etc., and achieve the effects of improving combustion performance and effect, mild action, and improved combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

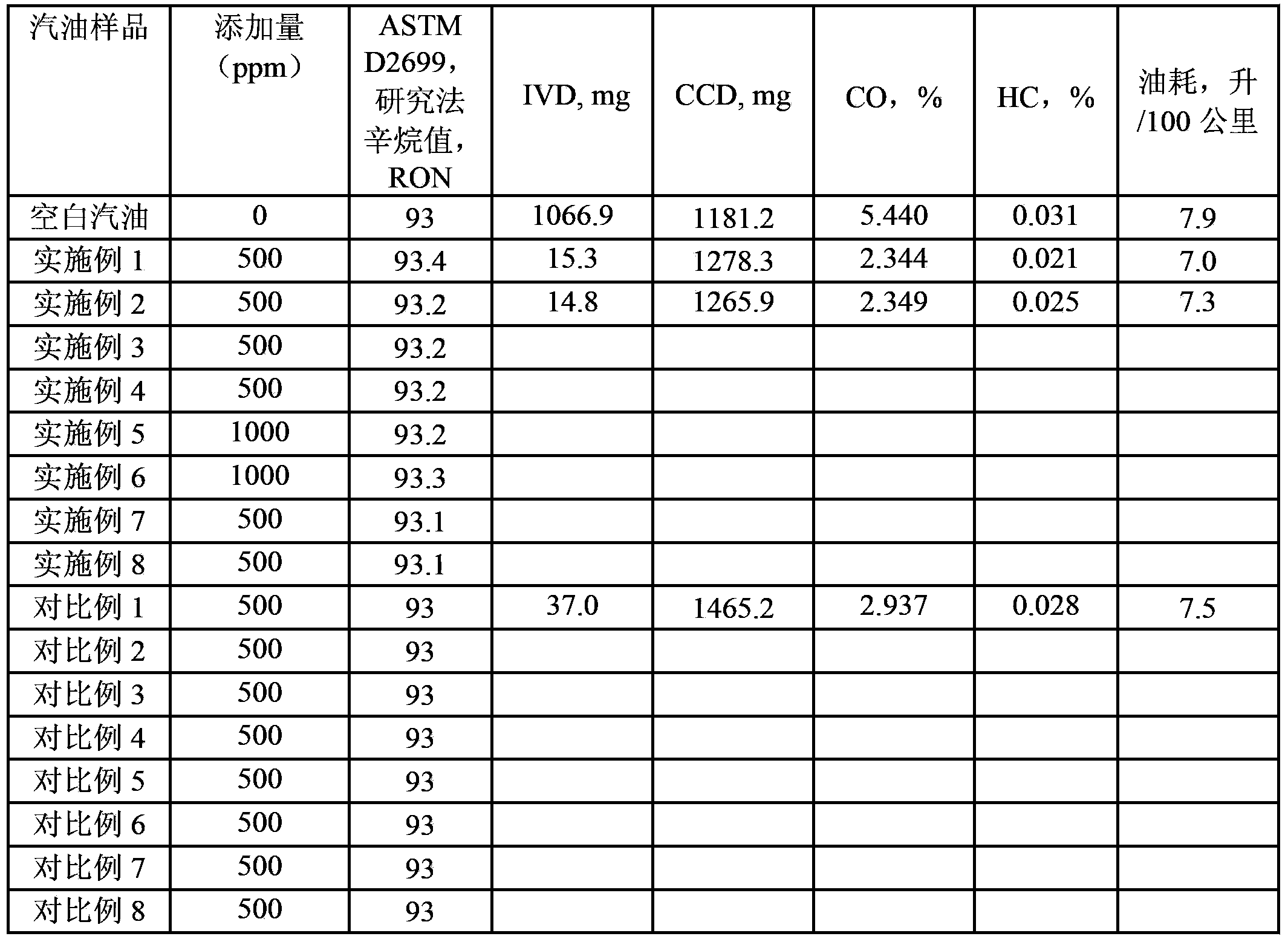

Examples

Embodiment 1

[0040] The gasoline composite additive described in this embodiment includes a detergent, a carrier agent and a biological enzyme in a weight ratio of 1:6:0.1, wherein:

[0041] Described detergent is polyisobutenyl amine 1000g;

[0042] Described carrier is mineral oil 6000g;

[0043] The biological enzyme is 100g, including: sulfonase 0.5g, alcohol oxidase 8g, aldehyde oxidase 0.5g, amine oxidase 7.5g, sulfhydryl oxidase 2g, methylthiol oxidase 8g, menaquinone oxidation 1g enzyme, 22.5g peroxidase, 1g iron chelatase, 26g demethylase, 1g decarboxylase, 9g aldolase, 0.5g oxyacid lyase, 8g alcohol, acid and ester dehydratase, dehydratase Thiolase 0.5g, desulfurization methylase 4g, cobalt chelase trace, magnesium chelase trace.

[0044] The above detergents, carrier agents and biological enzymes are tempered and formed into gasoline complex additives at room temperature to 60°C according to selected amounts.

Embodiment 2

[0046] The gasoline composite additive described in this embodiment includes a detergent, a carrier agent and a biological enzyme in a weight ratio of 1:3:3.1, wherein:

[0047] Described detergent is polyisobutenyl polyamine 28 parts by weight;

[0048] Described carrier is 84 parts by weight of poly-alpha olefin;

[0049] The biological enzyme is 88 parts by weight, including: 4 parts by weight of sulfonase, 1 part by weight of alcohol oxidase, 9 parts by weight of aldehyde oxidase, 1 part by weight of amine oxidase, 11 parts by weight of sulfhydryl oxidase, methyl mercaptan 2 parts by weight of oxidase, 8 parts by weight of menaquinone oxidase, 5 parts by weight of peroxidase, 8 parts by weight of ferrochelatase, 7 parts by weight of demethylase, 17 parts by weight of decarboxylase, 1 part by weight of aldolase Parts by weight, 8 parts by weight of oxyacid lyase, 1.5 parts by weight of alcohol, acid and ester dehydratase, 4 parts by weight of desulfurylase, 0.5 part by wei...

Embodiment 3

[0052] The gasoline composite additive described in this embodiment includes a detergent, a carrier agent and a biological enzyme in a weight ratio of 1:0.7:5, wherein:

[0053] The detergent is 19.2 parts by weight of polyisobutenyl amine;

[0054] The carrying agent is 4.7 parts by weight of polyisobutylene and 8.74 parts by weight of polyether;

[0055] The biological enzyme is 96 parts by weight, including: 3 parts by weight of sulfonase, 3 parts by weight of alcohol oxidase, 7 parts by weight of aldehyde oxidase, 3 parts by weight of amine oxidase, 7 parts by weight of sulfhydryl oxidase, methanethiol 3 parts by weight of oxidase, 7 parts by weight of menaquinone oxidase, 10 parts by weight of peroxidase, 6 parts by weight of ferrochelatase, 15 parts by weight of demethylase, 15 parts by weight of decarboxylase, 3 parts by weight of aldolase Parts by weight, 7 parts by weight of oxyacid lyase, 3 parts by weight of alcohol, acid and ester dehydratase, 3 parts by weight of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com