Preparation method of high-purity longifolene

A longifolene, high-purity technology, applied in chemical instruments and methods, distillation purification/separation, hydrocarbon purification/separation, etc., can solve the problem of low content of longifolene products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

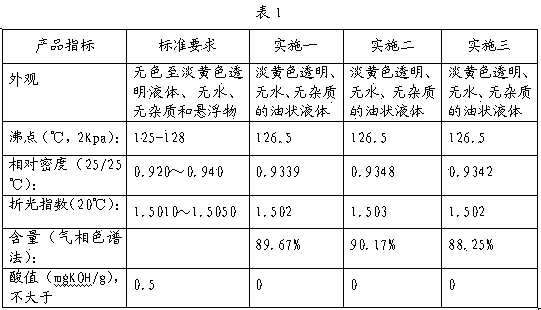

Embodiment 1

[0010] The small-scale test method of this high-purity longifolene, enters 100 grams of 65% longifolene primary products in a 250-gram three-necked flask with a thermometer, a stirrer and a spherical condenser as a raw material, and then adds 10 grams of high-efficiency solid acid D113 is used as a catalyst, i.e. macroporous weakly acidic acrylic cation exchange resin D113, then start the agitator to start heating, the reaction temperature is controlled at 60°C°, and the caryophyllene content is sampled and analyzed after 3 hours, and the sample is taken every 0.5-1 hour , until the content of caryophyllene is less than 3%, stop adding and start to cool down, lower the temperature to below 40 degrees, then filter in turn, recover the catalyst, and finally obtain the analysis results of the crude product of longifolene: the content of longifolene is 68.755%, and the content of caryophyllene is 2.2% %. The longifolene crude product is distilled and rectified, and the longifolene...

Embodiment 2

[0013] Expanded test of this high-purity longifolene: add 10,000 grams of 60% longifolene in a 20L reactor with condensation and stirring device, and then add 1000 grams of high-efficiency solid acid D113 as a catalyst, that is, macroporous weakly acidic Acrylic cation exchange resin D113, then start the agitator to start heating, control the reaction temperature to 90°C, take samples and analyze the caryophyllene content after 3 hours, take a sample every 0.5-1 hour, stop until the caryophyllene content is less than 3% After adding, the temperature was lowered, and the temperature was lowered to below 40 degrees, followed by filtration and catalyst recovery. Finally, the analysis results of the crude longifolene were obtained: the content of longifolene was 62.245%, and the content of caryophyllene was 2.3%. The longifolene crude product is distilled and rectified, and the longifolene with the required content (more than 80%, 85% or 90%) is intercepted according to the custome...

Embodiment 3

[0016] The pilot test implementation of this high-purity longifolene is as follows: add 63% longifolene 100kg longifolene / pot in the pilot test reactor, and then add 10kg high-efficiency solid acid D113 as a catalyst, that is, macroporous weakly acidic acrylic acid It is cation exchange resin D113, then start the agitator to start heating, control the reaction temperature to 110°C, take a sample to analyze the caryophyllene content after 3 hours, take a sample every 0.5-1 hour, stop adding until the caryophyllene content is less than 3%. Lower the temperature to below 40 degrees, then filter and recover the catalyst in sequence, and finally obtain the analysis results of the crude longifolene: the content of longifolene is 63.135%, and the content of caryophyllene is 2.5%. The longifolene crude product is distilled and rectified, and the longifolene with the required content (more than 80%, 85% or 90%) is intercepted according to the customer's index requirements, which is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com