Transparent plastic part manufacturing method and transparent plastic part manufacturing system

A manufacturing method and technology of a manufacturing system, applied in the direction of coating, can solve the problems of shrinkage of injection molded parts, inability to inject transparent plastic parts, etc., to eliminate welding marks, meet the needs of appearance design, and prevent the effect of being too thick and unable to be injected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0036] The invention provides a method for manufacturing a transparent plastic part.

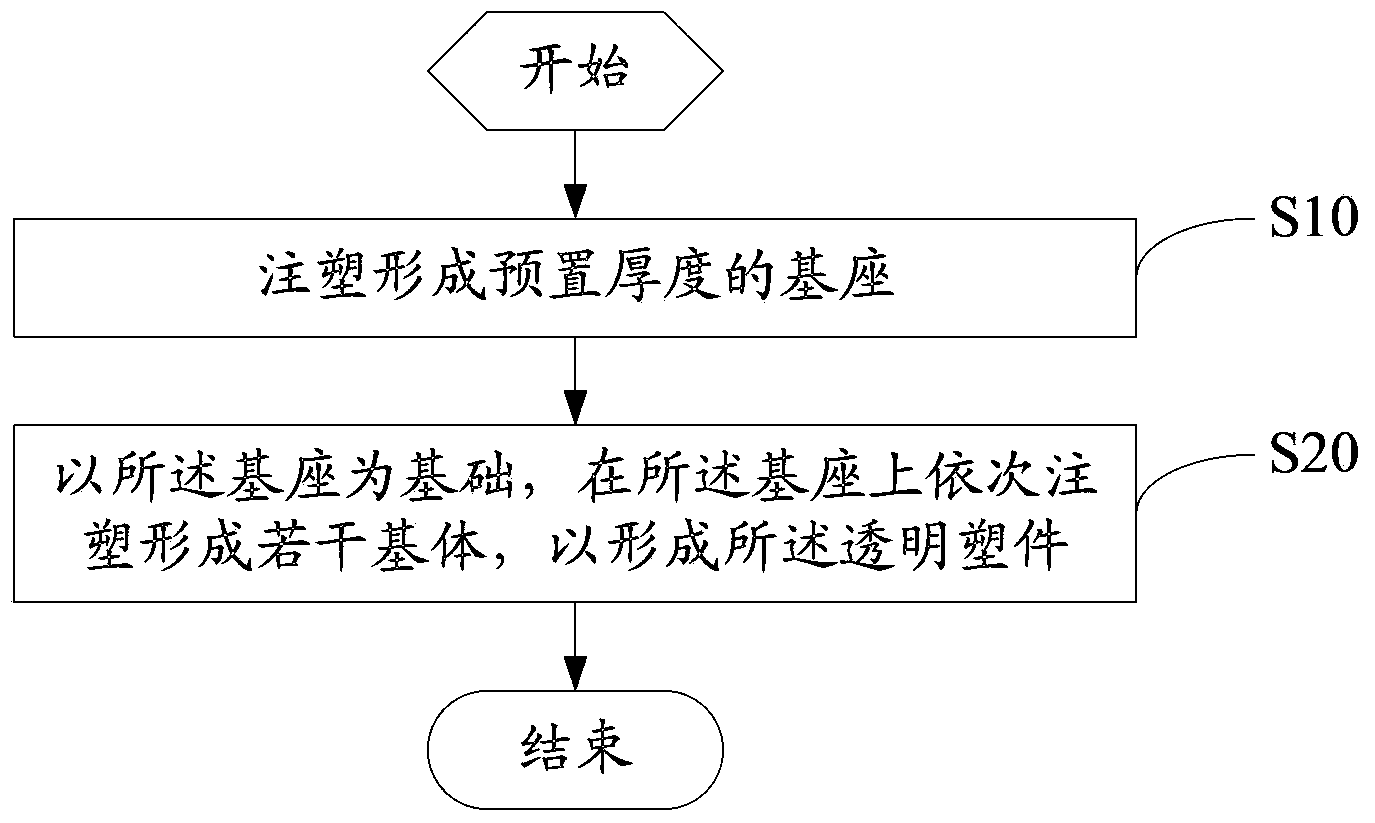

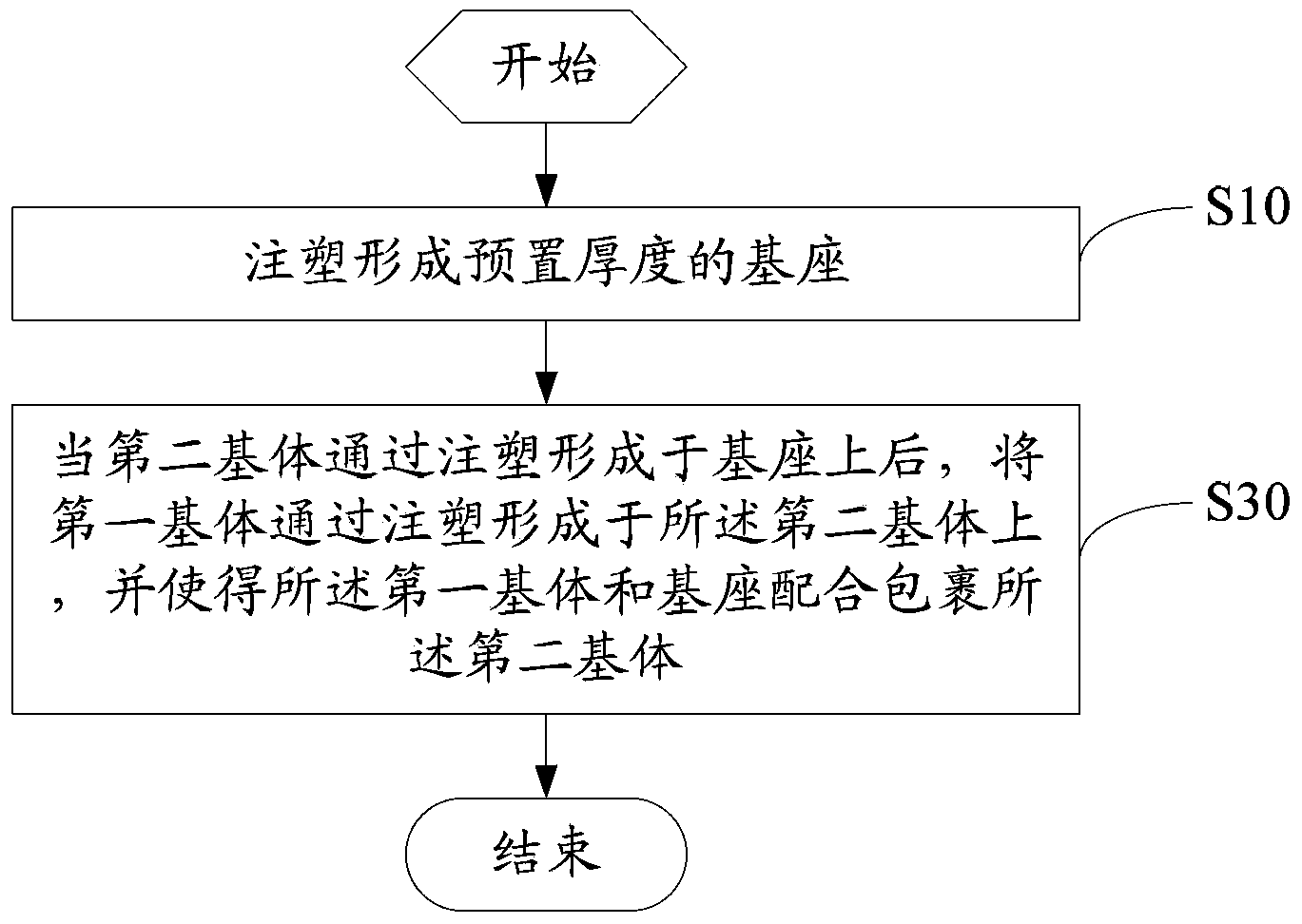

[0037] refer to figure 1 , figure 1 It is a schematic flow chart of an embodiment of the manufacturing method of the transparent plastic part of the present invention. The manufacturing method of the transparent plastic part provided in this embodiment includes the following steps.

[0038] Step S10, forming a base with a preset thickness by injection molding;

[0039] Step S20, based on the base, sequentially injection molding several substrates on the base to form the transparent plastic part.

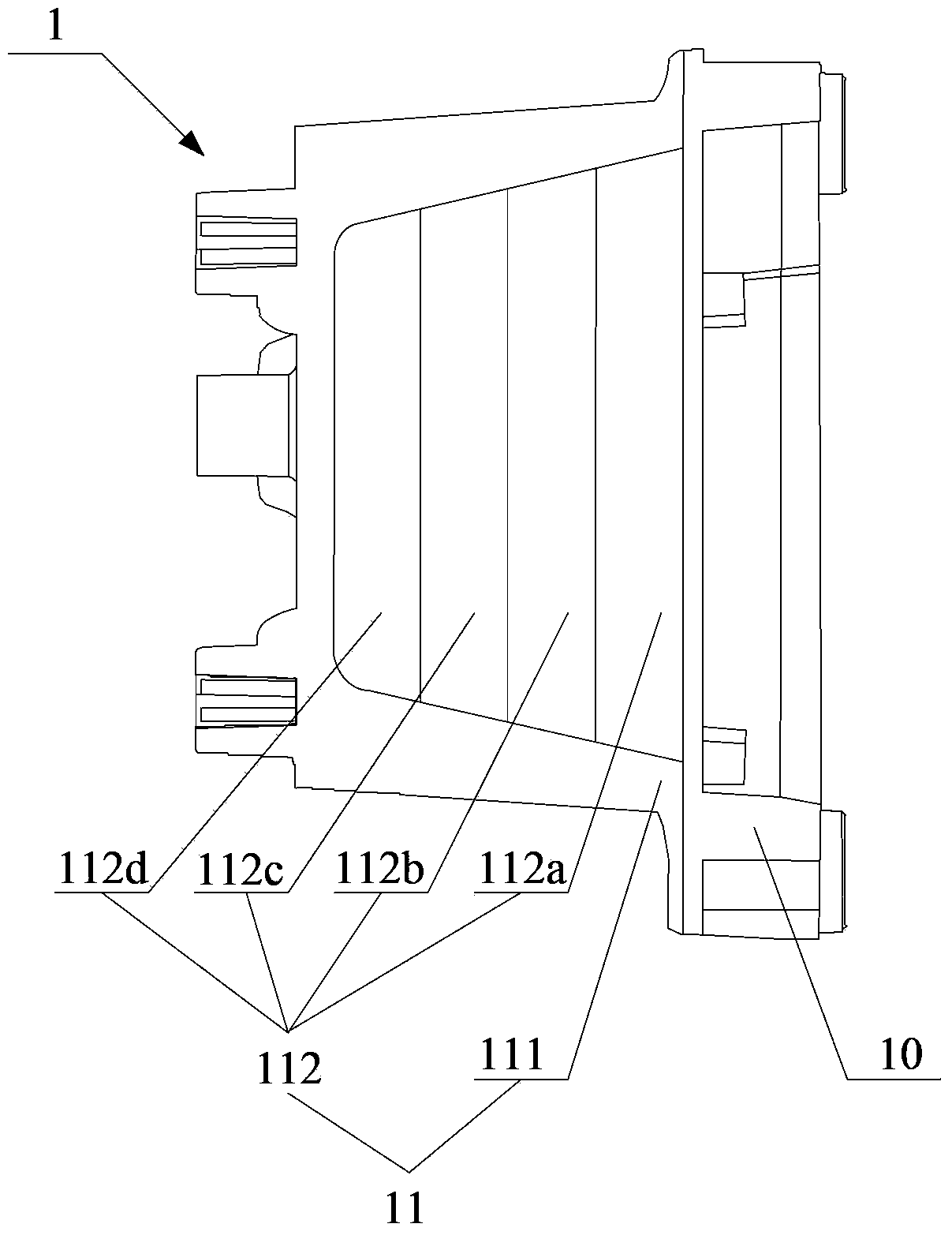

[0040] combined reference figure 2 , figure 2 It is a schematic structural diagram of a transparent plastic part in a preferred embodiment of the present invention. In this embodiment, the thickness of the above-mentioned base 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com