A kind of automobile head lamp and its assembly structure and the assembly method of the assembly structure

An assembly structure and front roof technology, which is applied in the direction of headlights, lighting device parts, lighting device damage prevention measures, etc., can solve the problems of bloated structure, single appearance, and large space occupation, and achieve multiple functions and assembly efficiency High, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

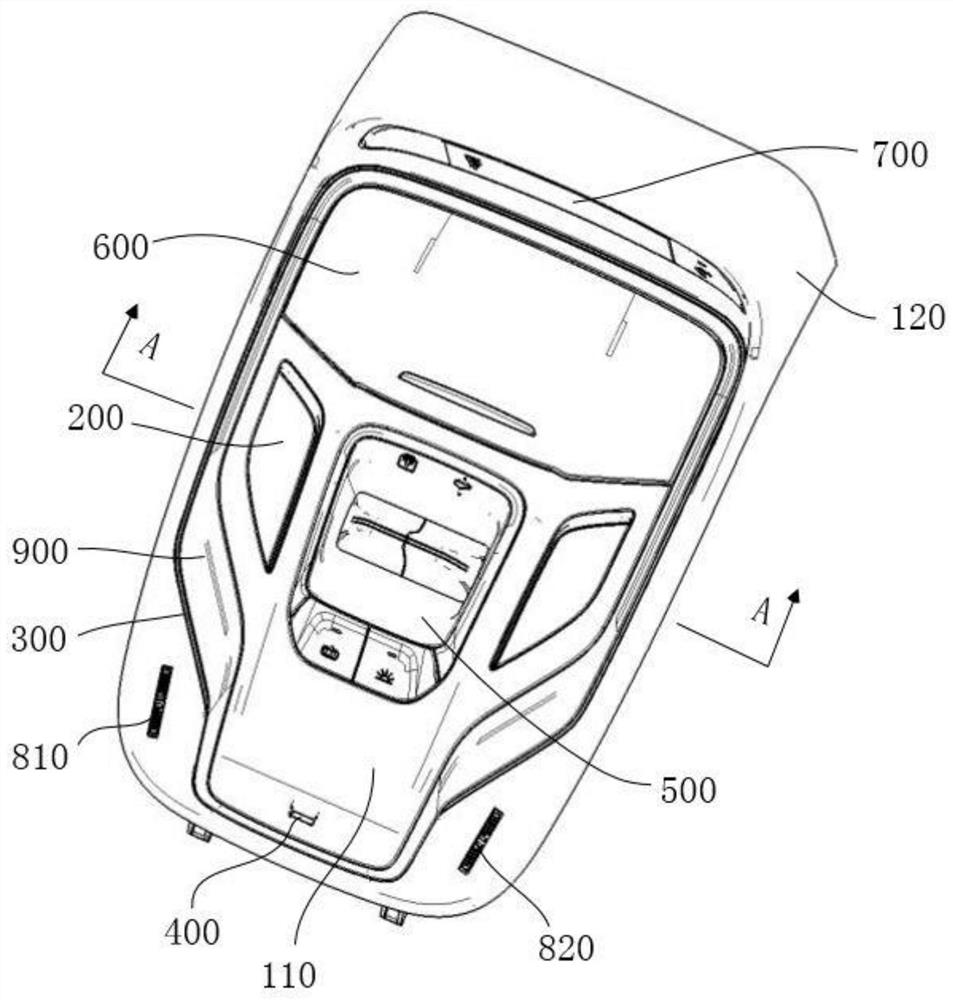

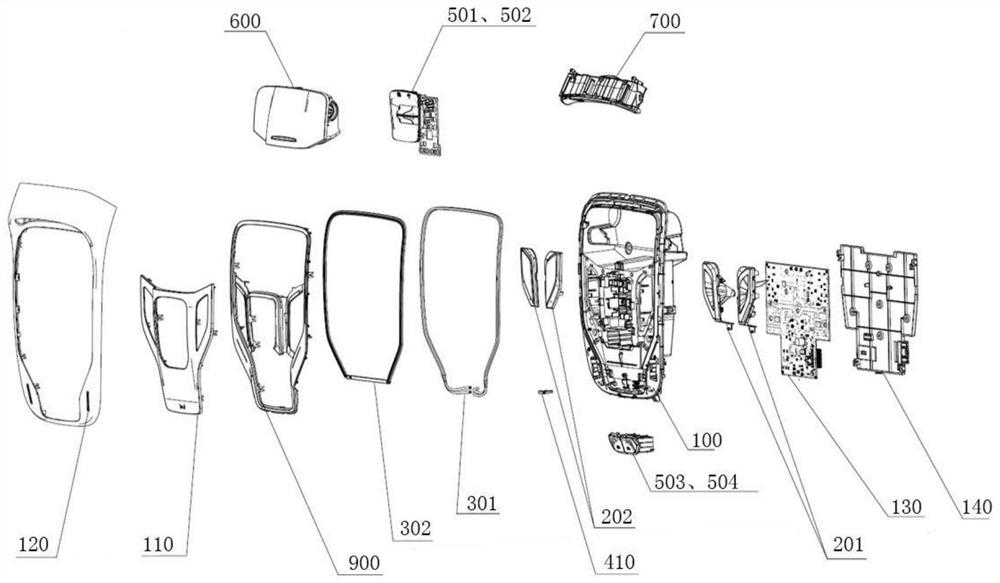

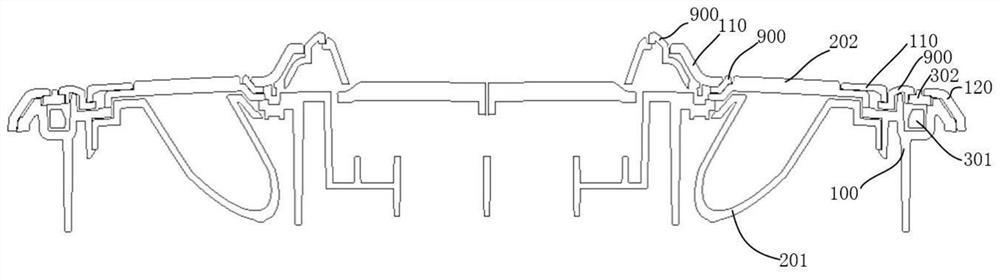

[0030] See attached figure 1 , attached figure 2 , attached image 3 , the invention discloses an automobile front dome lamp and an assembly structure thereof.

[0031] The headlights include:

[0032] - Housing 100

[0033] Used to install other components that house the headlight.

[0034] - Reading light unit 200

[0035] The reading light unit 200 is used to illuminate the driver's seat and the passenger's seat. When the light in the car is insufficient, it can provide enough brightness for the occupants to facilitate reading in the car. The reading light unit 200 includes a light source, a reading light reflecting bowl 201 and a reading light mask 202 . Preferably, the reading light includes a left reading light and a right reading light, which are used to illuminate the driver's seat and the co-pilot's seat resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com