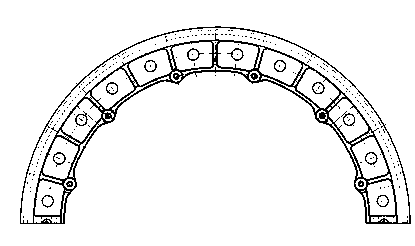

Process for preventing deformation of wheel disk of semi-gear rim

A technology of semi-gear and radial plate, which is applied in the field of preventing the deformation of the semi-gear and radial plate, can solve the problems of large riser volume, large shrinkage, slow cooling speed, etc., meet the requirements of feeding, improve the quality of castings, Guarantee the effect of qualified size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

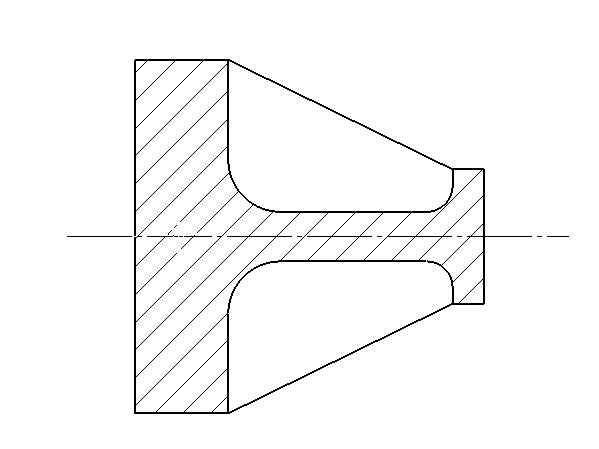

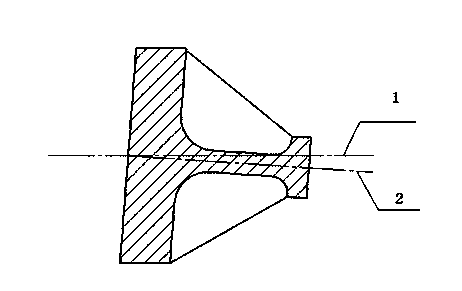

[0015] As attached when casting Figure 4 As shown, the machining amount of the outer circle of the rim is placed obliquely, so that the casting can be artificially solidified sequentially, so that the part of the casting away from the riser solidifies first, then the part close to the riser solidifies, and finally the riser itself Solidification, and control the temperature gradient of the solidification process. The specific method is: control the ratio of the riser modulus to the casting hot section modulus; use different pouring methods; use heat-insulating materials to control the temperature gradient from the casting to the riser. Prevent excessive shrinkage of the outer circle of the rim due to excessive shrinkage of the riser, resulting in insufficient machining of the outer circle, resulting in the scrapping of the half ring gear.

[0016] The machining amount of the outer circle of the rim is placed obliquely, so that the casting can be artificially solidified sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com