Isothermal die forging technique of large-sized magnesium alloy component

A technology of isothermal die forging and magnesium alloy, applied in the field of warm die forging, can solve the problems of increasing die damage, difficulty in filling the cavity, and increasing cost, and achieves the effect of improving plastic deformation ability, reducing deformation difficulty and easy deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

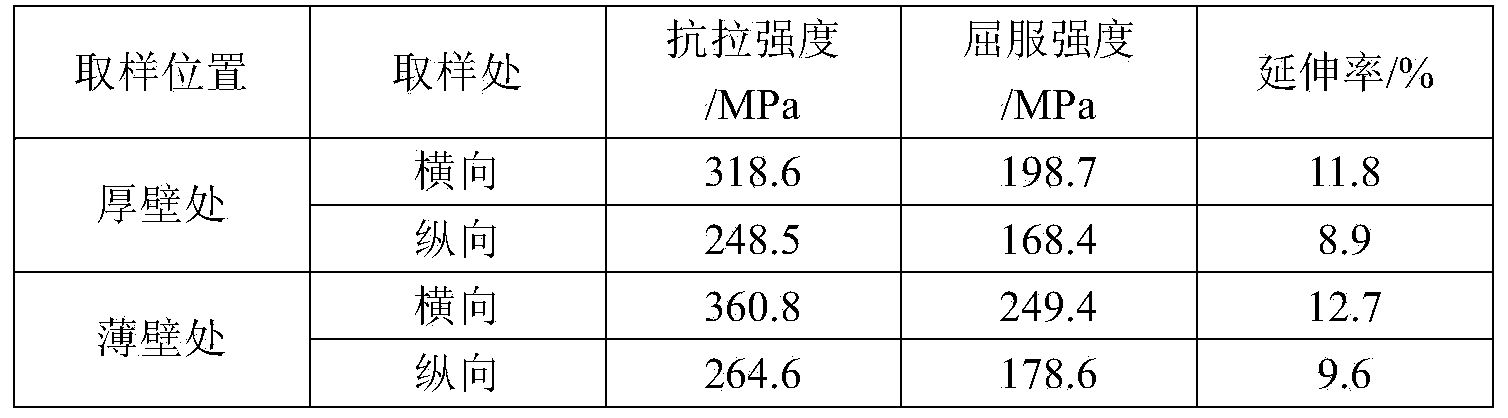

[0044] An isothermal die forging process for large-size magnesium alloy parts, the size is Φ670×100mm, and the composition is (wt.%): Al8.2~8.5; Mn0.2~0.25; Zn0.4~0.5; Cu≦0.05 ; Ni≦0.005; Si≦0.15; Be≦0.02; Fe≦0.05; Area up to 0.4m 2 magnesium alloy parts; including the following steps:

[0045] 1. Machining and flaw detection of billets: Remove visible cracks and scale on the surface of large-size magnesium alloy forging cakes and process them into billets with a size of Φ670×100mm. Ultrasonic waves are used to detect flaws on the billets to ensure that there are no obvious cracks and shrinkage inside the billets. Hole, inclusion defects;

[0046] 2. Billet heating: place the processed billet in a resistance furnace, heat it to 380°C, and keep it warm for 6 hours;

[0047] 3. Fix the lower mold base in the isothermal forming heater, fix the upper and lower molds on the upper and lower mold bases respectively, the matching gap between the mold and the reference plane of the ...

Embodiment 2

[0052] An isothermal die forging process for large-size magnesium alloy parts, the size is Φ670×100mm, and the composition is (wt.%): Al8.2~8.5; Mn0.2~0.25; Zn0.4~0.5; Cu≦0.05 ; Ni≦0.005; Si≦0.15; Be≦0.02; Fe≦0.05; Projected area up to 0.45m 2 magnesium alloy parts; including the following steps:

[0053] 1. Machining and flaw detection of billets: Remove visible cracks and scale on the surface of large-size magnesium alloy forging cakes and process them into billets with a size of Φ670×100mm. Ultrasonic waves are used to detect flaws on the billets to ensure that there are no obvious cracks and shrinkage inside the billets. Hole, inclusion defects;

[0054] 2. Blank heating: place the processed blank in a resistance furnace, heat it to 420°C, and keep it warm for 3 hours;

[0055] 3. Fix the lower mold base in the isothermal forming heater, fix the upper and lower molds on the upper and lower mold bases respectively, the matching gap between the mold and the base surface o...

Embodiment 3

[0060] An isothermal die forging process for large-size magnesium alloy parts, the size is Φ670×100mm, and the composition is (wt.%): Al8.2~8.5; Mn0.2~0.25; Zn0.4~0.5; Cu≦0.05 ; Ni≦0.005; Si≦0.15; Be≦0.02; Fe≦0.05; Horizontal projection area up to 0.5m 2 magnesium alloy parts; including the following steps:

[0061] 1. Machining and flaw detection of billets: Remove visible cracks and scale on the surface of large-size magnesium alloy forging cakes and process them into billets with a size of Φ670×100mm. Ultrasonic waves are used to detect flaws on the billets to ensure that there are no obvious cracks and shrinkage inside the billets. Hole, inclusion defects;

[0062] 2. Blank heating: place the processed blank in a resistance furnace, heat it to 400°C, and keep it warm for 5 hours;

[0063] 3. Fix the lower mold base in the isothermal molding heater, fix the upper and lower molds on the upper and lower mold bases respectively, the matching gap between the mold and the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com