Rough rolling temperature-measuring feedback control method

A temperature measurement feedback and control method technology, which is applied in temperature control, heat treatment process control, manufacturing tools, etc., to achieve the effects of ensuring output, avoiding frequent adjustments, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention is not limited thereto.

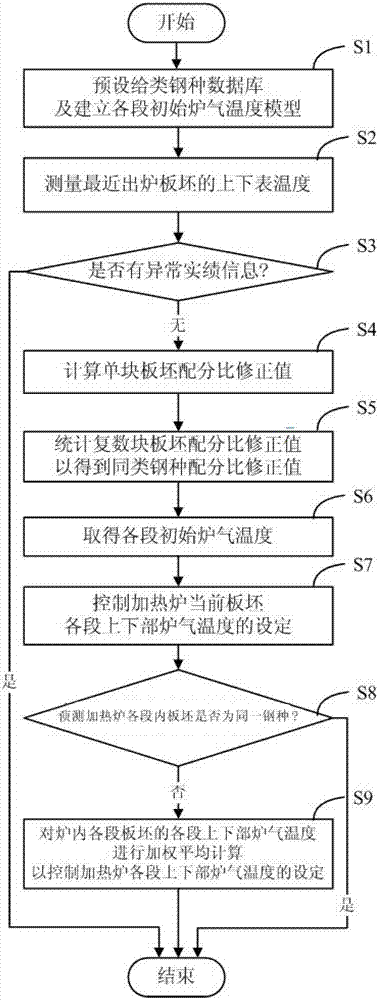

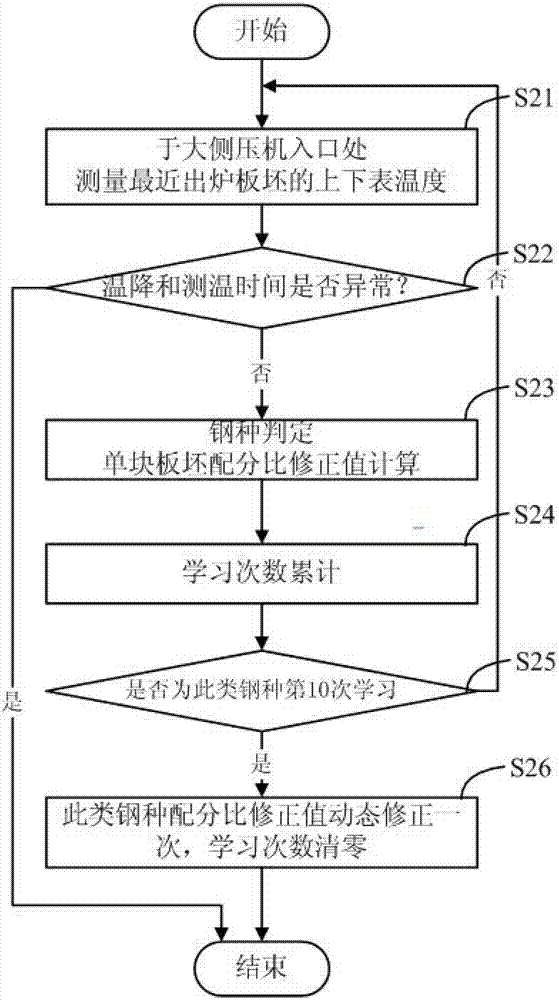

[0051] figure 1 It is a schematic flow chart of the rough rolling temperature measurement feedback control method of the present invention, the method comprises the following steps:

[0052]In step S1, the steel-type database is preset and the initial furnace gas temperature model of each section is established, and then step S2 is performed. Among them, the pre-set steel type database includes: set the steel type and its corresponding expected temperature difference between the upper and lower tables, the learning coefficient and the weight database in the controllable section; and the initial furnace gas temperature model of each section is based on the use of furnace, furnace The specific rules will be detailed in the following steps for the establishment of the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com