A cone type tartary buckwheat hulling device

The technology of tartary buckwheat and conical cylinder is applied in the directions of grain hulling, grain processing and application, which can solve the problems of low hulling rate and whole kernel rate, loss of nutrients in tartary buckwheat, etc. value, the effect of reducing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

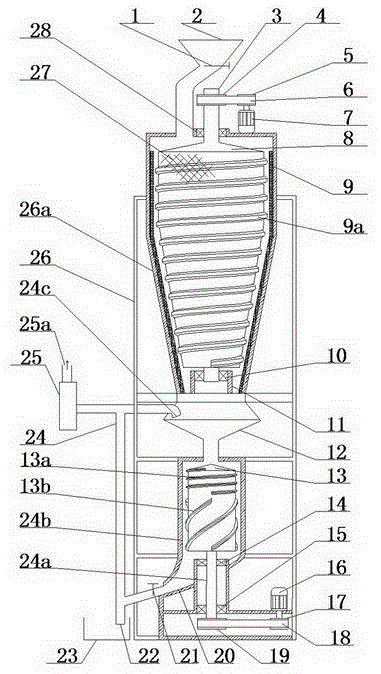

[0030] Embodiment 1: A cone type tartary buckwheat hulling device

[0031] Such as figure 1 It is a conical tube type tartary buckwheat hulling device, comprising a frame 26, a conical grinding cylinder 26a is vertically fixed in the middle of the frame 26, and a conical grinding roller 8 is concentrically installed inside the conical grinding cylinder 26a; There is a gap of 1 to 4 times the diameter of the shelled grain between the cylinder 26a and the inner conical grinding roller 8, and the gap gradually decreases from top to bottom at the conical portion of the conical grinding cylinder 26a. The inner wall of the conical grinding cylinder 26a has a grinding cylinder abrasive layer 9; the conical grinding roller 8 has a grinding roller abrasive layer 27; the cylindrical surface and the conical surface of the conical grinding roller 8 also have a grinding roller spiral 9a , the rotation direction of the grinding roller spiral 9a cooperates with the rotation direction of the...

Embodiment approach 2

[0040] Embodiment 2: A method of using a cone type tartary buckwheat shelling device

[0041] Pour tartary buckwheat grains with appropriate moisture content from the feed hopper 2, and control the feed flow rate through the feed valve 1. After the grains pass through the feed valve 1, they fall into the gap between the conical grinding roller 8 and the conical grinding cylinder 26a. The gap is large at the top and small at the bottom, so that the material forms a certain accumulation in the gap, and falls under the action of gravity as a whole; during the falling process of the material, the abrasive layer on the surface of the conical grinding cylinder 26a and the conical grinding roller 8 grinds the material shell , so that the husks at the corners are worn away and gradually become white (the kernels at the corners leak out), and the bonding strength of the husks of the grains is greatly reduced. During the grinding process, the grinding roller spiral 9a on the roller surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com