Method for cooperatively degrading organic matters by visible light photoelectric-Fenton

A technology of synergistic degradation and visible light, applied in the direction of protection devices against harmful chemicals, etc., can solve the problems of high cost, human injury, hindering popularization and application, etc., to achieve the effect of simple operation, reducing compounding, and improving photocatalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

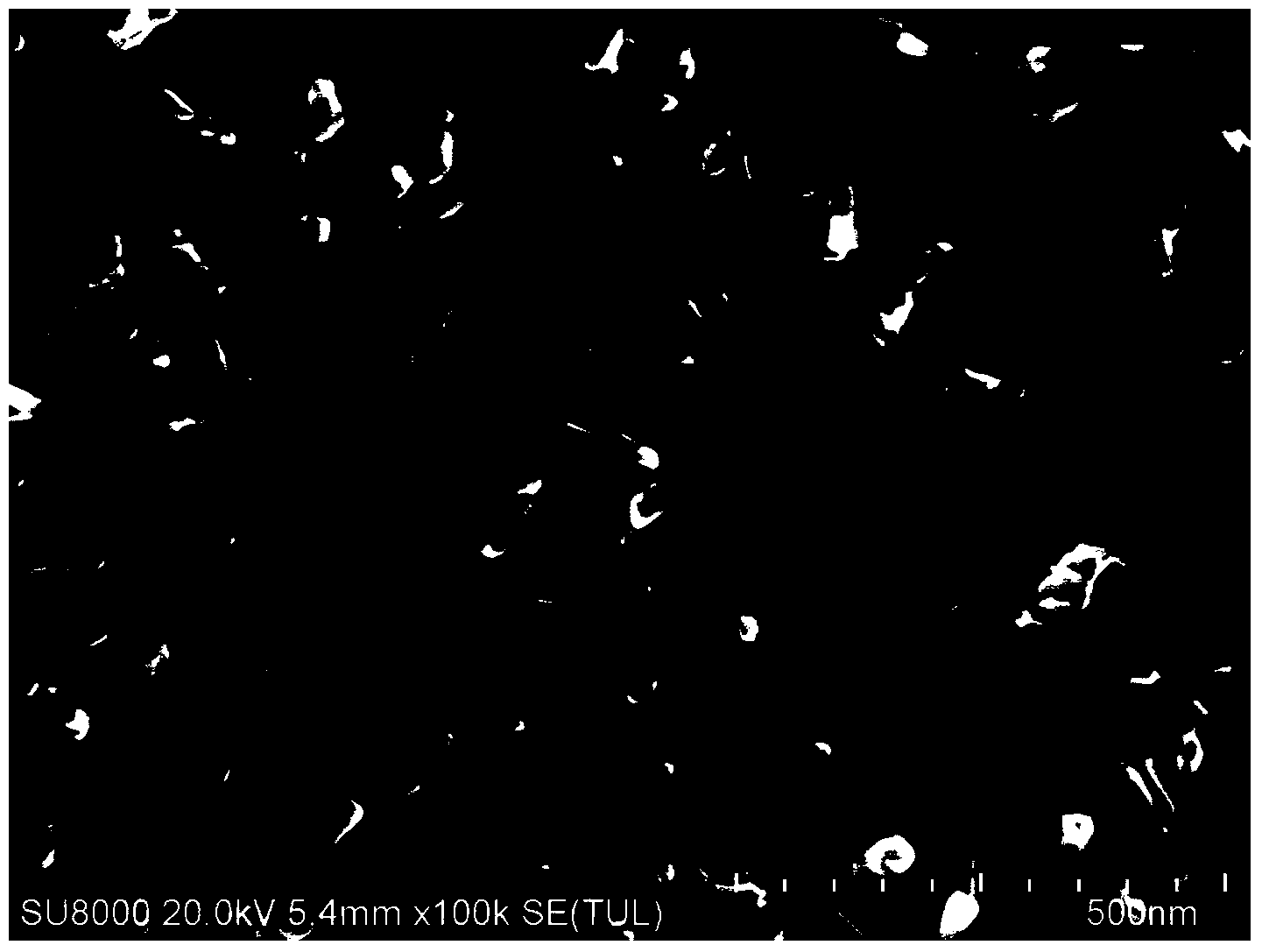

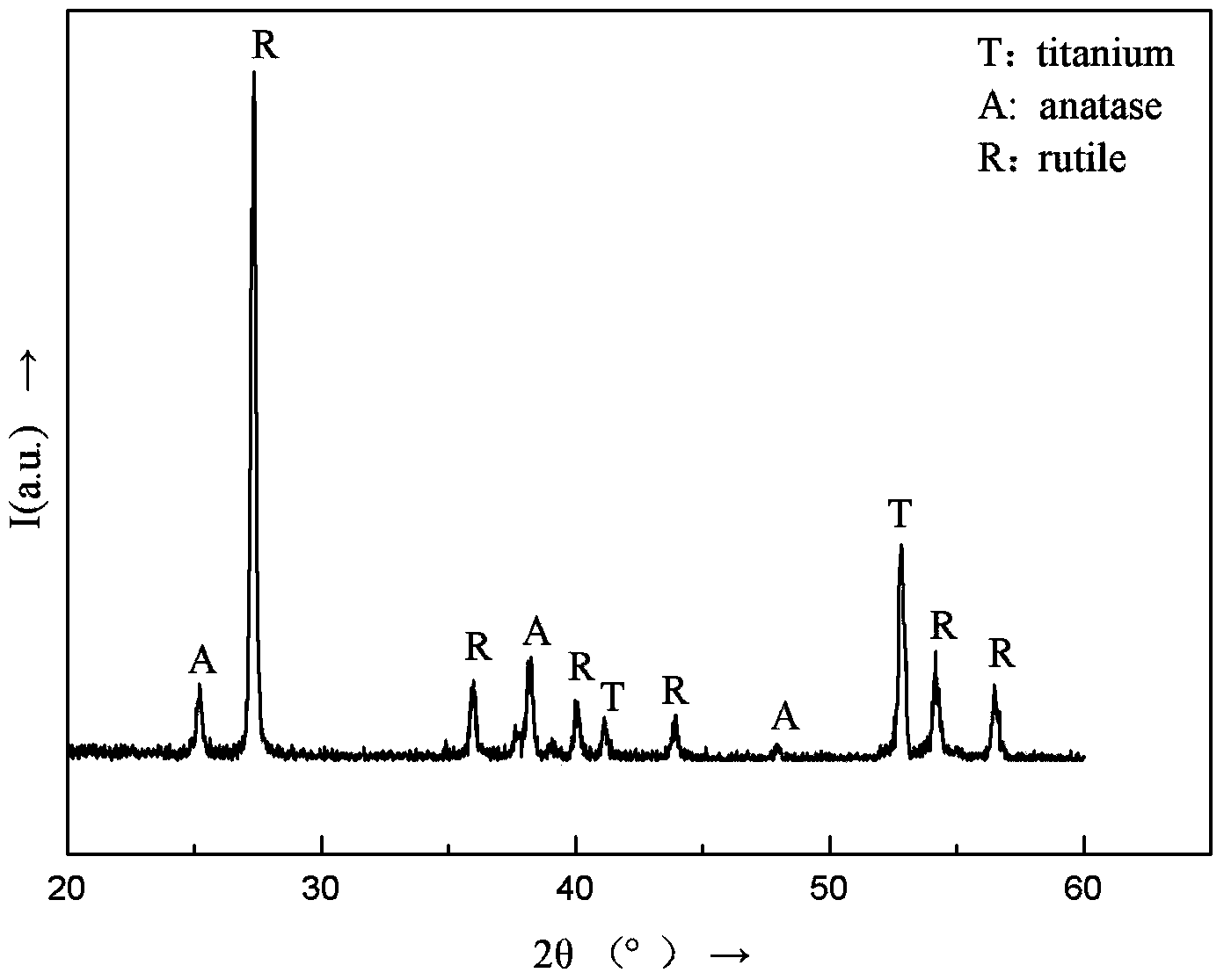

[0028] Polish the Ti-based substrate with a purity >99.6% with metallographic sandpaper of 500#, 1000#, and 1500# in sequence until the surface is smooth, and then immerse in a volume ratio of HF:HNO 3 :H 2 Chemical polishing was carried out in the polishing solution of O=1:4:5 for 30 s, and then cleaned in an ultrasonic cleaner with acetone and pure water in sequence. The treated Ti-based substrate was used as the anode, the graphite electrode was used as the cathode, and the distance between the anode and the cathode was 4 cm. 4 The mixed solution of F and glycerol is used as the electrolyte, the volume ratio of glycerol to water is 1:9, and it contains NH 4 The concentration of F is 0.5 wt%. Use copper wires as wires to connect the two stages to a DC stabilized power supply for electrochemical anodic oxidation. In this reaction, the controlled voltage was 30 V, and the anodic oxidation time was 90 min, to obtain amorphous mesoporous TiO 2 Thin film electrode; after 120 ...

Embodiment 2

[0032] Polish the Ti-based substrate with a purity >99.6% with metallographic sandpaper of 500#, 1000#, and 1500# in sequence until the surface is smooth, and then immerse in a volume ratio of HF:HNO 3 :H 2 Chemical polishing was carried out in the polishing solution of O=1:4:5 for 30 s, and then cleaned in an ultrasonic cleaner with acetone and pure water in sequence. The treated Ti-based substrate was used as the anode, the graphite electrode was used as the cathode, and the distance between the anode and the cathode was 5 cm, and the NH 4 The mixed solution of F and glycerol is used as the electrolyte, the volume ratio of glycerol to water is 1:9, and it contains NH 4 The concentration of F is 0.3 wt%. Use copper wires as wires to connect the two stages to a DC stabilized power supply for electrochemical anodic oxidation. In this reaction, the controlled voltage was 10 V, and the anodic oxidation time was 150 min to obtain amorphous mesoporous TiO 2 Thin film electrode;...

Embodiment 3

[0036] Polish the Ti-based substrate with a purity >99.6% with metallographic sandpaper of 500#, 1000#, and 1500# in sequence until the surface is smooth, and then immerse in a volume ratio of HF:HNO 3 :H 2 Chemical polishing was carried out in the polishing solution of O=1:4:5 for 30 s, and then cleaned in an ultrasonic cleaner with acetone and pure water in sequence. The treated Ti-based substrate was used as the anode, the graphite electrode was used as the cathode, and the distance between the anode and the cathode was 3 cm. 4 The mixed solution of F and glycerol is used as the electrolyte, the volume ratio of glycerol to water is 1:9, and it contains NH 4 The concentration of F is 0.2 wt%. Use copper wires as wires to connect the two stages to a DC stabilized power supply for electrochemical anodic oxidation. In this reaction, the controlled voltage was 40 V, and the anodic oxidation time was 90 min to obtain amorphous mesoporous TiO 2 Thin film electrode; after 120 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com