A clamping claw for thermosetting cutting knife

A technology of cutting knives and clamping claws, which is applied in the field of medical machinery, can solve the problems of claws scalding internal tissues, small load-bearing capacity of clamping claws, and difficult production, so as to prevent overheating and broken wires, accurate temperature setting, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

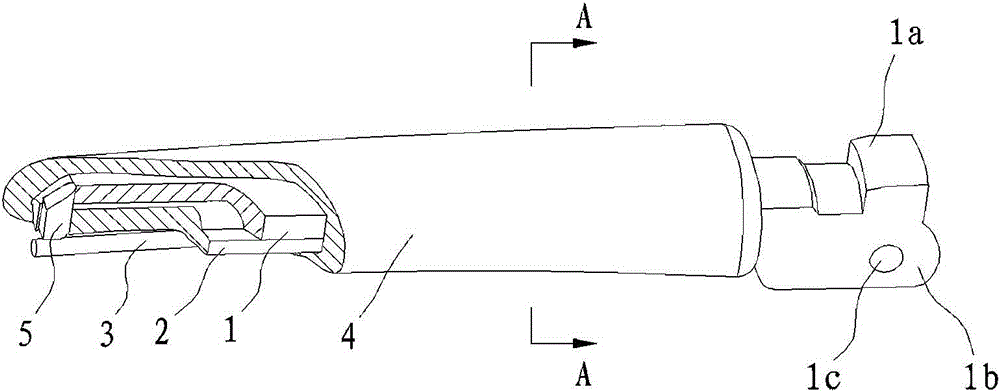

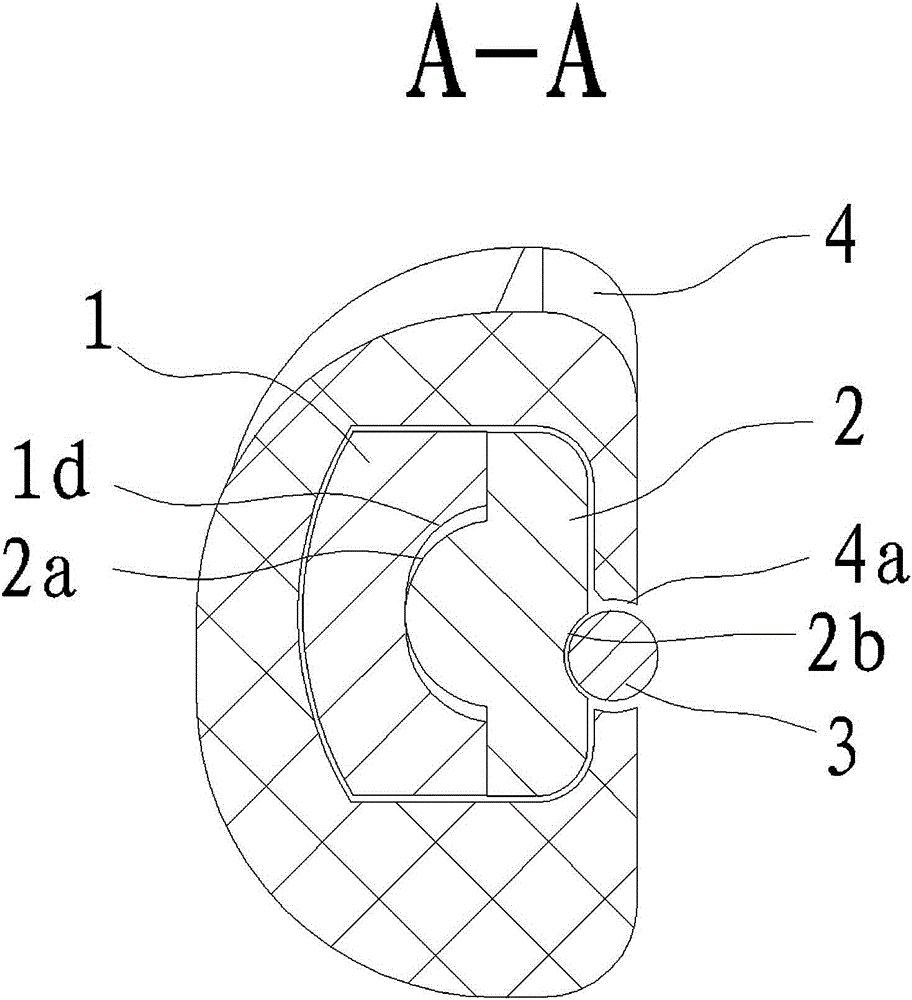

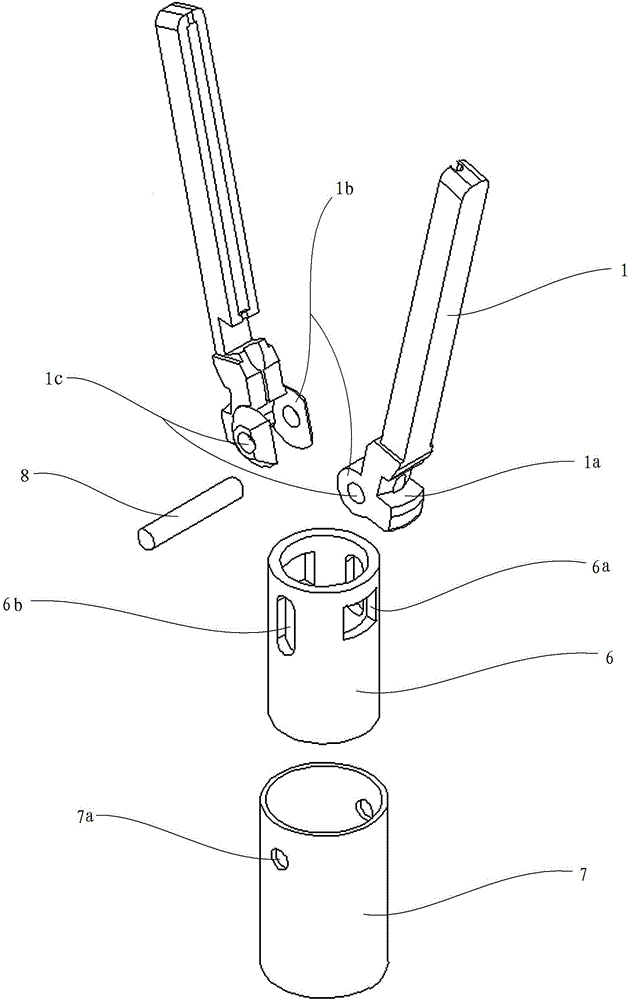

[0020] Such as figure 1 and figure 2 As shown, the present invention provides a clamping claw for thermal coagulation cutting knife, comprising a claw body 1, a heating wire 3 is arranged on the claw body 1, and a claw shell 4 is arranged outside the claw body, and is characterized in that:

[0021] a. A connection block 1b is provided on the inner surface of the rear end of the claw body 1, a pin hole 1c is provided on the connection block 1b, and a square board 1a is provided on the outer surface of the rear end of the claw body 1. The inner surface of the clamping part of 1 is provided with a groove 1d, and the isolation layer 2 is matched and connected in the groove 1d, and a boss 2a is provided on one side of the isolation layer 2, and a relief groove 2b is provided on the other side. The boss 2a and the groove 1d are correspondingly matched, and a heating wire 3 is connected in the relief groove 2b. The isolation layer 2 and the heating wire 3 are sintered together, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com